Construction method for transverse beam hoisting in-position of arch first and beam late tied-arch bridge

A technology of tie-rod arch bridge, arch first and then beam, applied in arch bridges, bridges, bridge forms, etc., can solve the problems of potential safety hazards, heavy lifting burden of slings, and high construction costs, saving equipment and construction process, and reducing construction costs. Strength, the effect of reducing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

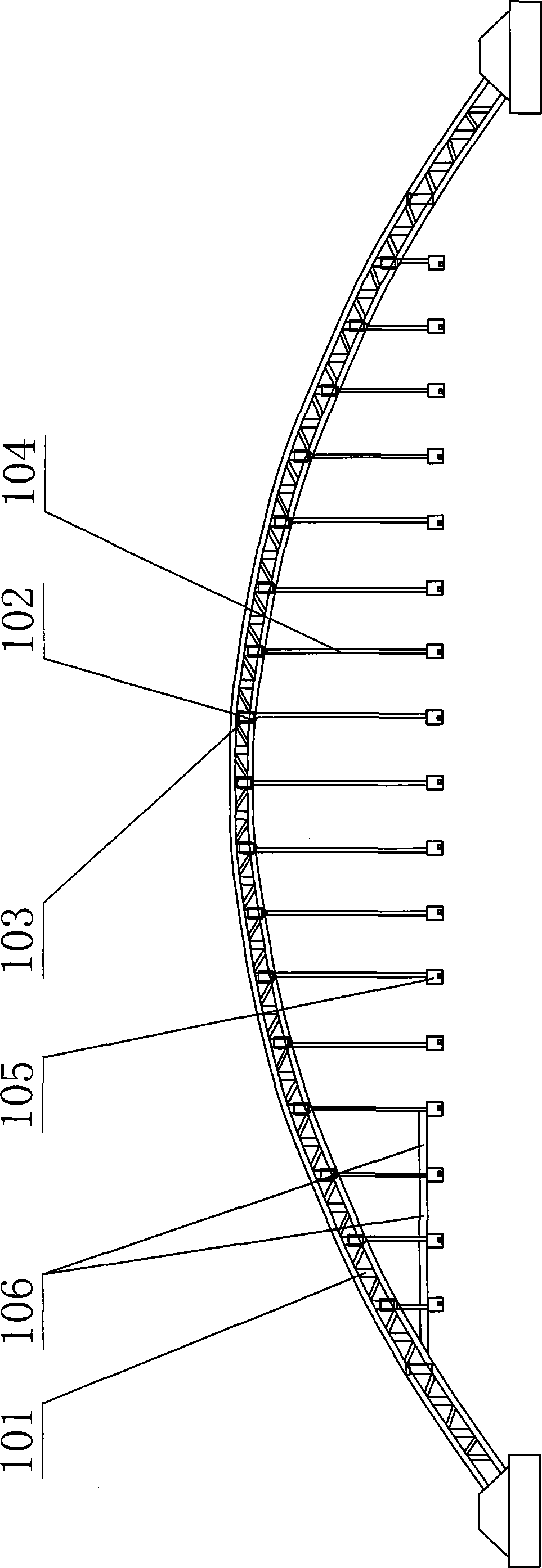

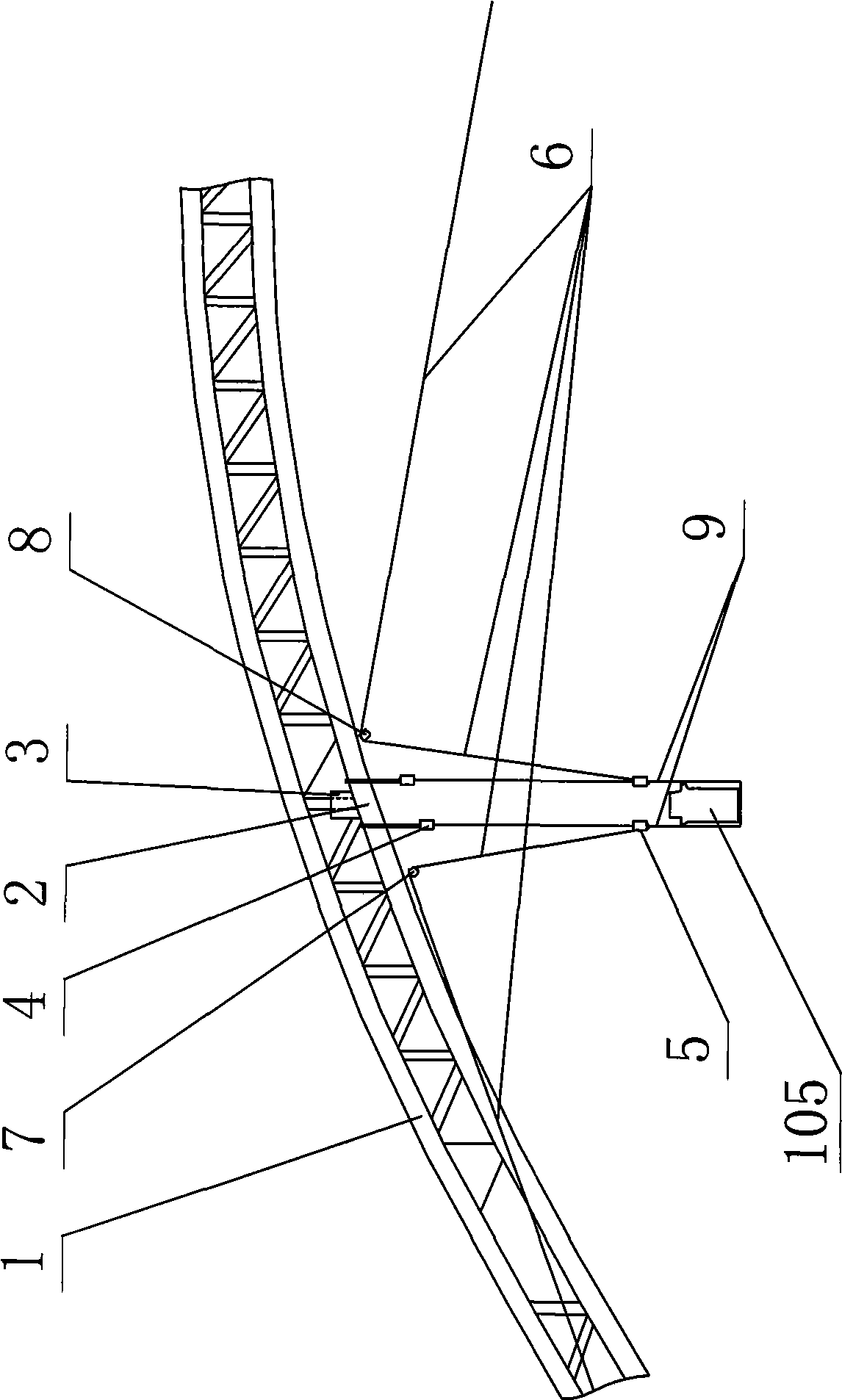

[0033] like figure 2 , image 3 , Figure 4 Shown, the construction method of the crossbeam hoisting in place of beam tie-rod arch bridge after first arch of the present invention, it comprises following construction steps:

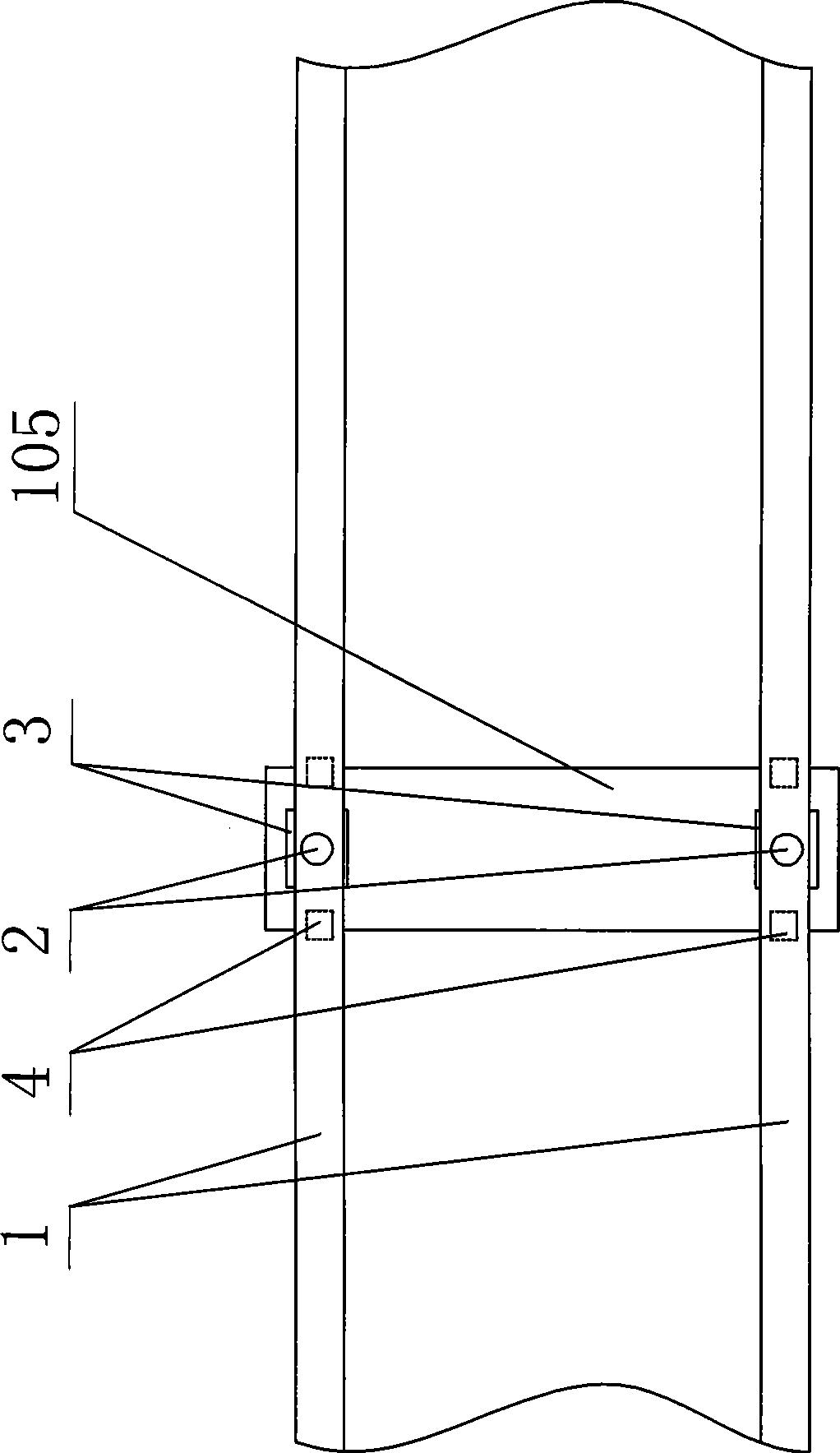

[0034] a. The construction personnel use the double-running head-through method to string the pulley group 4 and select an arch rib node 2 on the formed arch rib 1 across both banks of the river as the lifting point, and then stand beside the arch rib 1 for construction On the platform, the block block 4 is suspended under the anchor box 3 of the arch rib node 2, so that the two outgoing rope ends of the running rope 6 (steel cable) of the block block 4 are pulled out from the movable block, and the block block 4 Divide into two parts and hang on both sides below the anchor box 3, the number of moving blocks suspended ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com