Full-automatic dielectric oil chromatographic analysis system

A chromatographic analysis and insulating oil technology, which is applied in the field of automatic chromatographic analysis systems and detection and analysis instruments, can solve the problems that affect the accurate judgment of oil-filled electrical equipment failures, the impact of chromatographic analysis accuracy, and high requirements for operators, so that it is not easy to cross-contaminate, High degree of automation and good injection repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

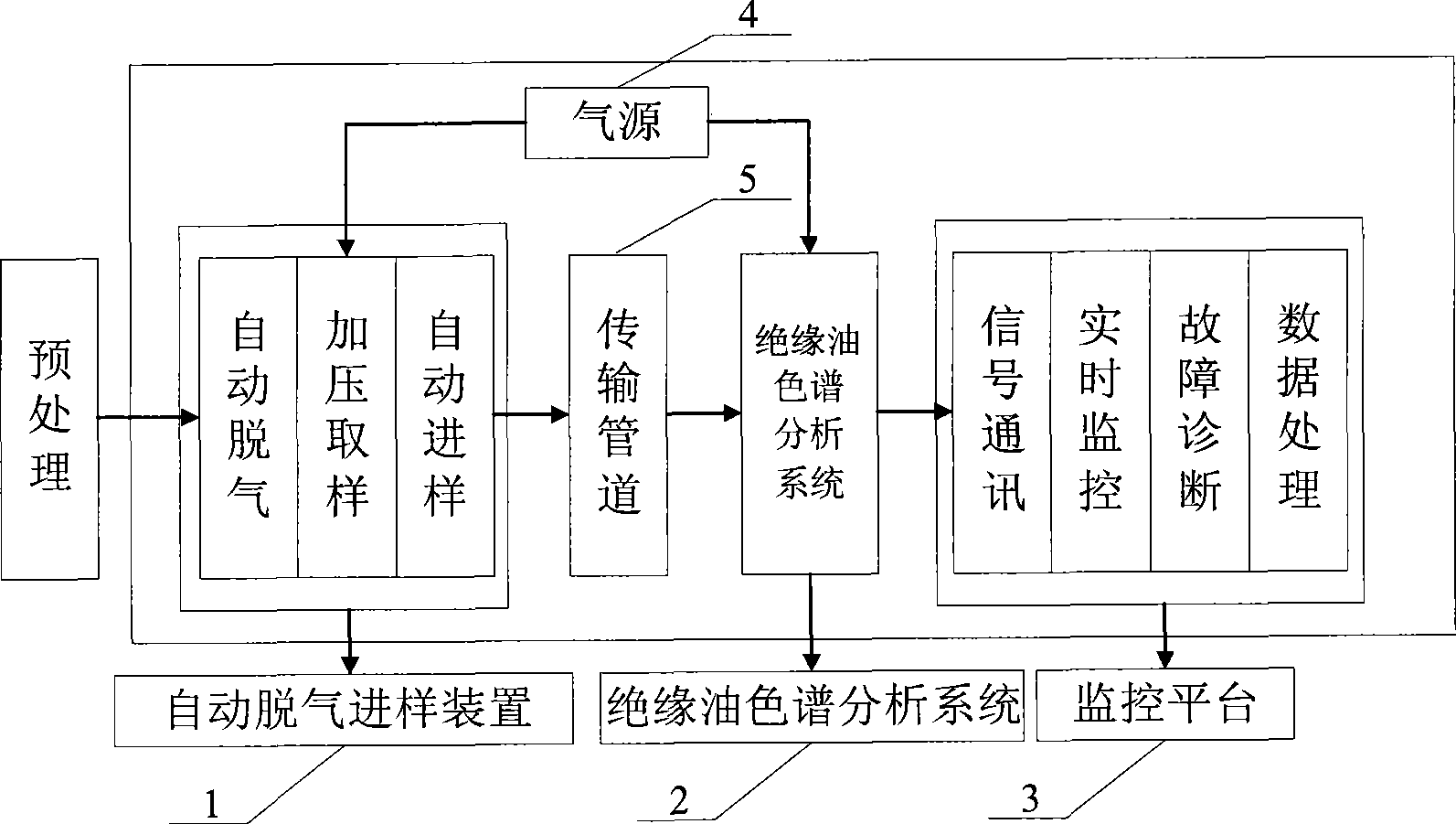

[0029] like figure 1 As shown, the automatic insulating oil chromatographic analysis system includes an automatic degassing and sampling device 1, an insulating oil chromatographic analysis system 2, and a monitoring platform 3.

[0030] The monitoring platform 3 includes signal communication, real-time monitoring, data processing, and fault diagnosis. The automatic degassing and sampling device includes automatic degassing, pressurized sampling, and automatic sampling. The transmission pipeline 5 adopts a Φ2mm silanized stainless steel tube.

[0031] The automatic degassing and sampling device 1 can load 12 samples at the same time, and can perform constant temperature oscillation degassing at the same time. One end of the transmission pipeline 5 is connected to the air outlet of the pressurized sampling device, and the other end is connected to the sample inlet of the insulating oil chromatography analysis system. , after the pretreated oil sample is degassed by constant te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com