Convergence belt for solar photovoltaic component and method for assembling solar panel by convergence belts

A solar photovoltaic and solar panel technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of ineffective heat dissipation, low labor efficiency, and many processes, and achieve the solution of difficult process assurance, improve labor efficiency, and reduce operations. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 6

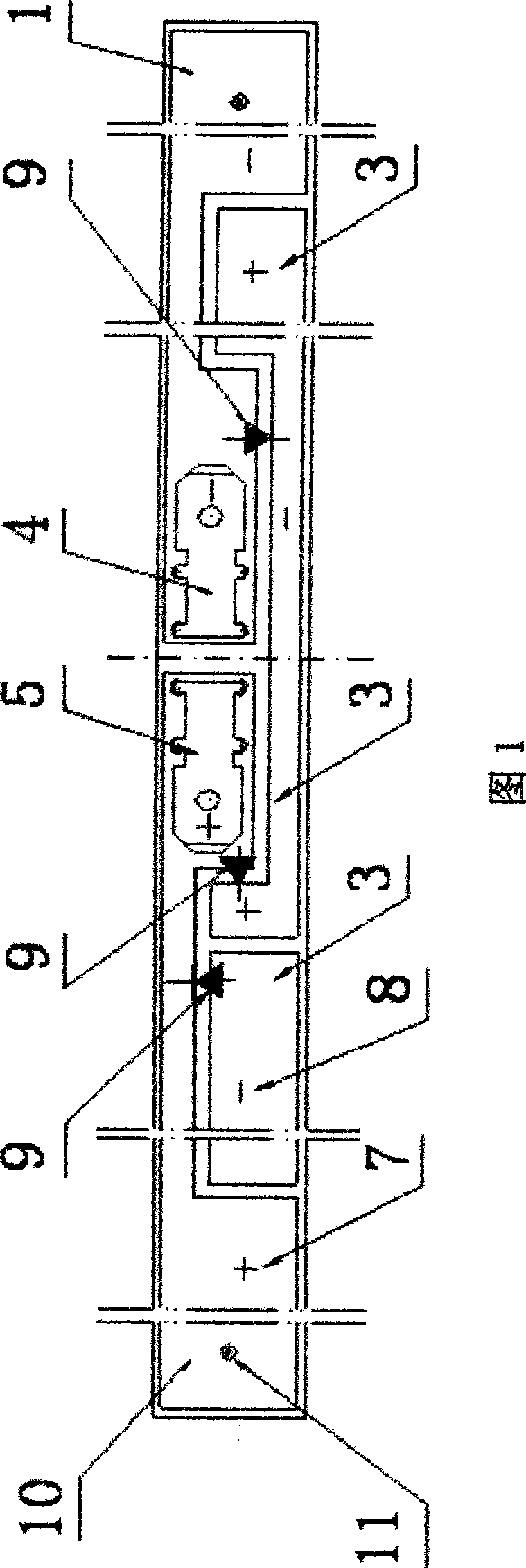

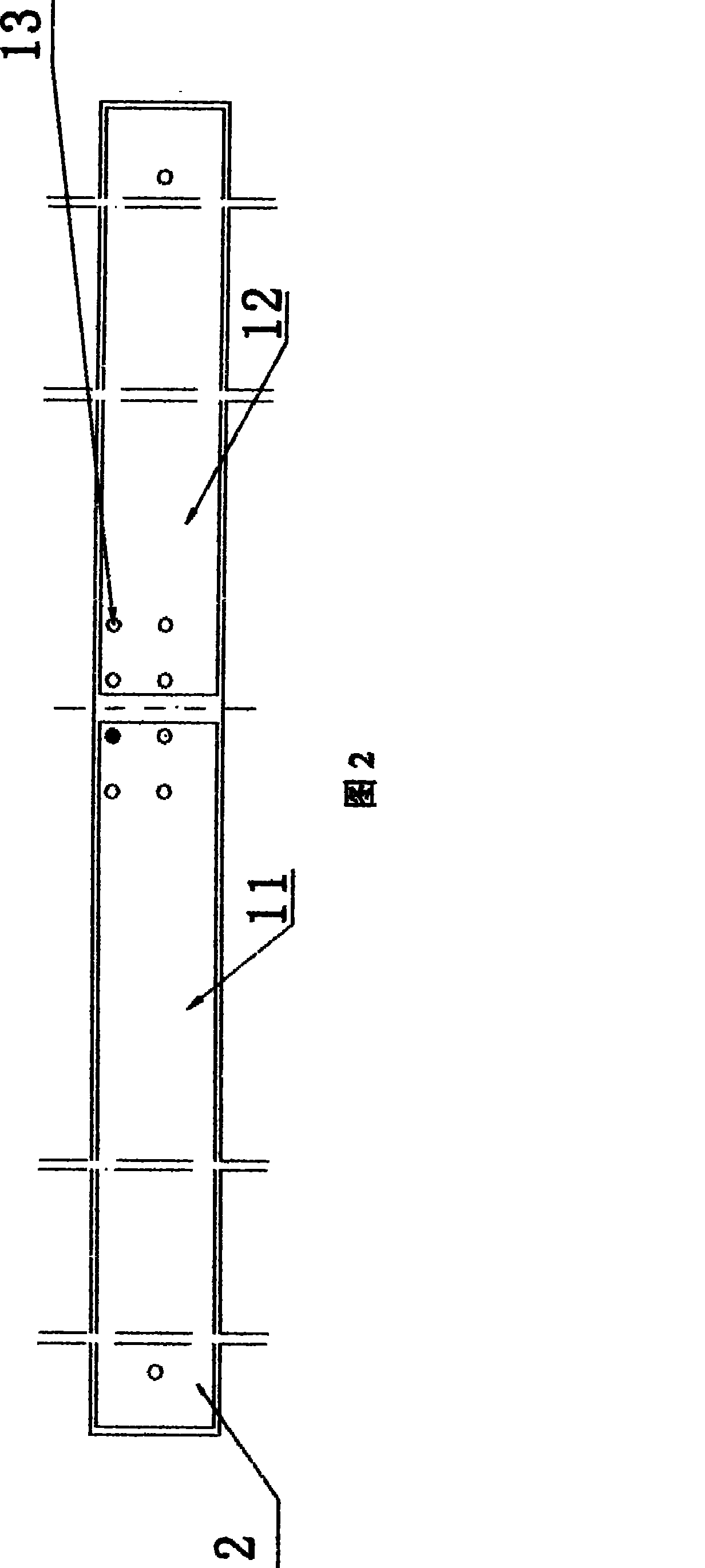

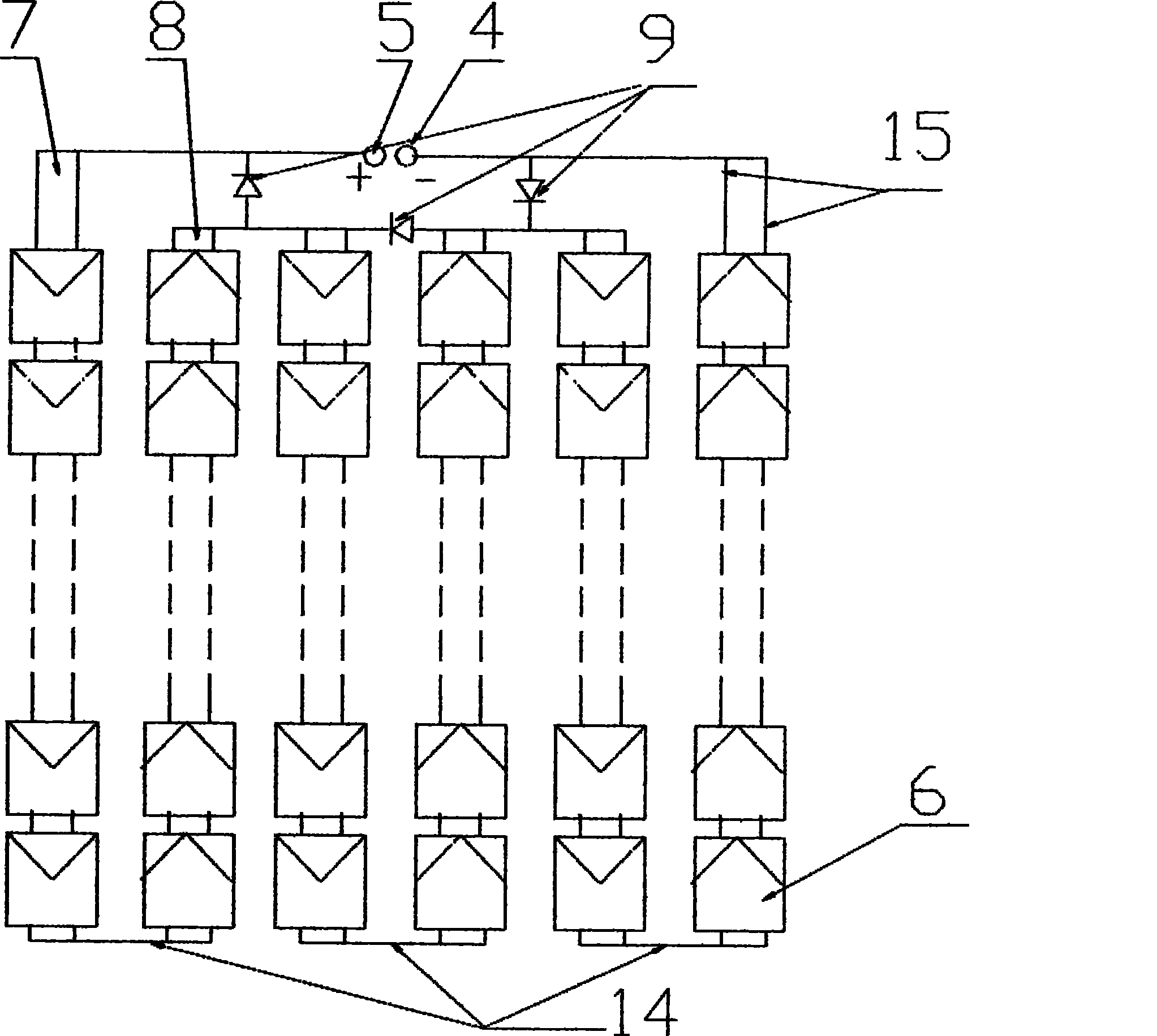

[0063] figure 1 It is a schematic diagram of the structure of the embodiment of the 6-string solar photovoltaic module. The confluence strip 1 is a long strip-shaped PCB board. Connect to the positive terminal of the load. Connecting terminal 4 is the negative terminal output, which is directly connected to the negative terminal of the load. There are pads 3 connected to the positive and negative poles of the solar photovoltaic module 6 along the length direction of the top layer 10 of the bus strip 1 PCB; In order to adapt to different solar photovoltaic modules 6 , the pad 3 can be a larger weldable surface. In this way, the solar photovoltaic module 6 can be large or small, and the position of the welding surface can be made to correspond to the electrode lead-out end of the solar photovoltaic module 6 . The positive pole 7 or negative pole 8 of the two-string loop solar photovoltaic module is connected to the negative pole 8 or positive pole 7 of the adjacent two-string...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com