Run flat tire

A run-flat tire and bead technology, which is applied in the direction of pneumatic tires, reinforcement layers of pneumatic tires, special tires, etc., can solve the problems of detachment of bead parts, weakening of extrusion pressure, and reduction of tire fitting force, and achieve suppression Bead shedding, suppression of vibration amplitude, and reduction of road noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

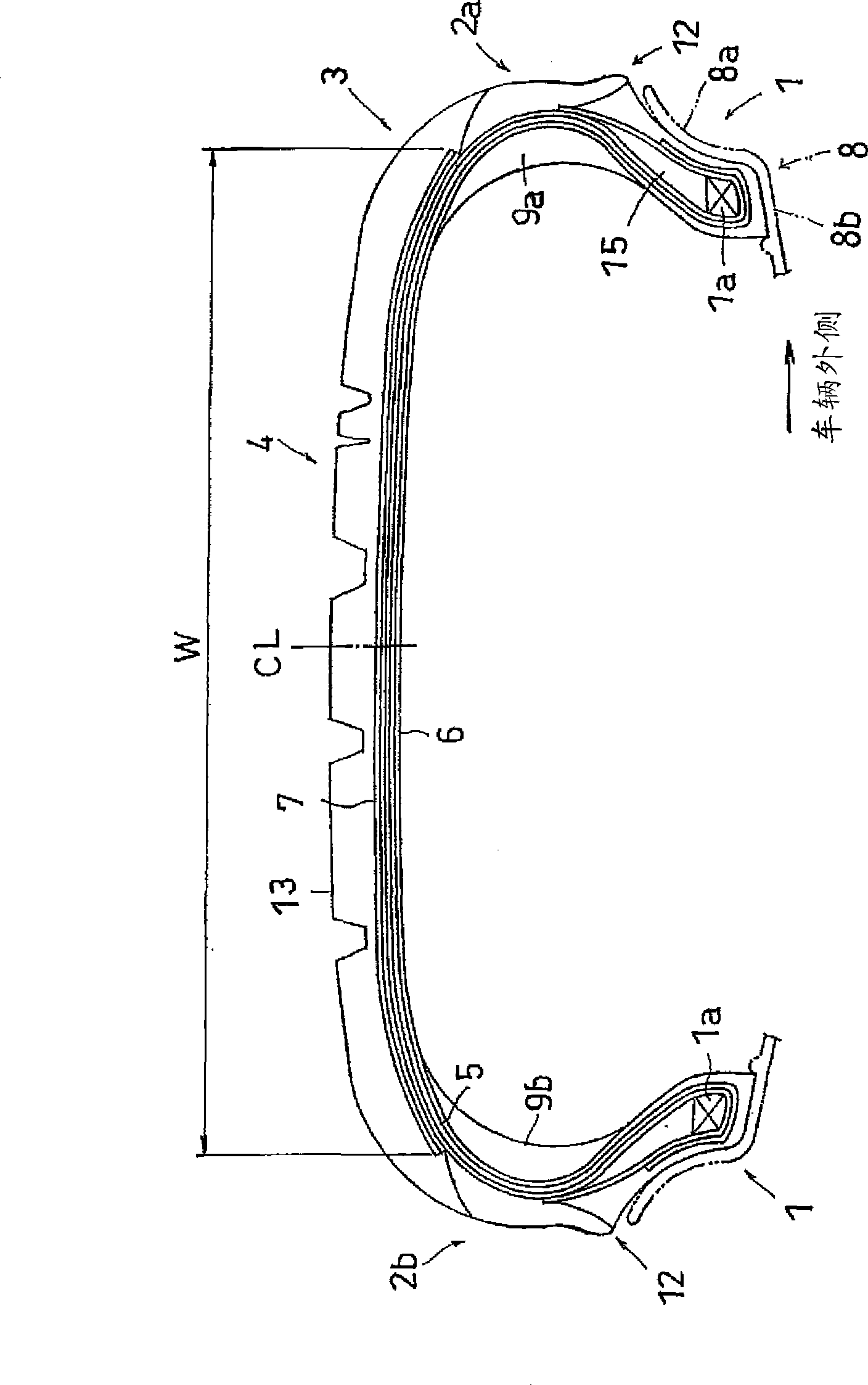

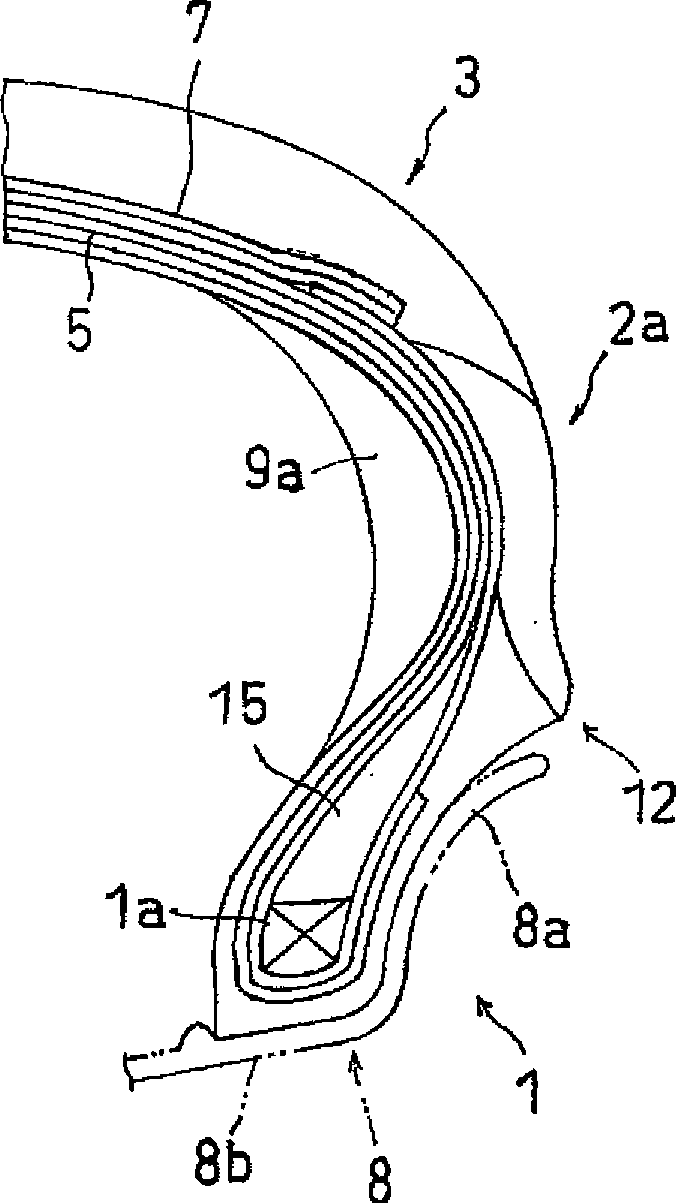

[0049] (1) In the above-mentioned embodiment, the case where the positions of the winding ends of the carcass layer are the same on both sides is exemplified. However, in the present invention, the winding part of the carcass layer extends to the high turn-up of the sidewall part. The structure is only applicable to the sidewall portion arranged on the outside of the vehicle, and thus an asymmetric rigid structure may be formed.

[0050] Such as figure 2 As shown, with this structure, the winding end of the carcass layer 5 arranged on the outside of the vehicle is located further outward in the tire radial direction than the inside of the vehicle, and the carcass is arranged only on the sidewall portion 2a arranged on the outside of the vehicle. The wound portion of the layer 5, therefore, the sidewall portion 2a has a higher rigidity than the sidewall portion 2b. In this example, the winding end of the carcass layer 5 arranged on the outside of the vehicle reaches the end of the ...

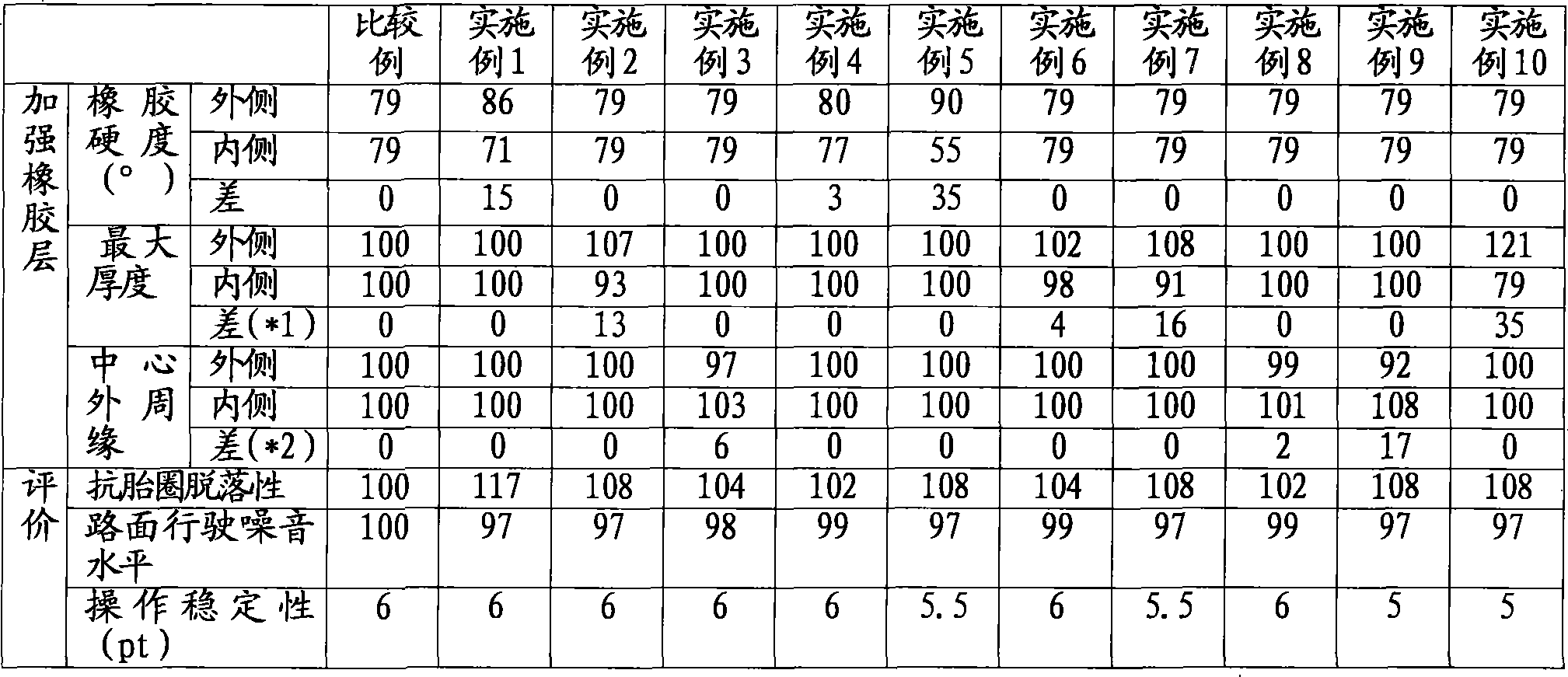

Embodiment

[0055] Hereinafter, an embodiment concretely showing the structure and effects of the present invention will be described. As evaluation items of the examples, etc., bead shedding resistance, road noise level, and operation stability were used, and the following evaluations were made.

[0056] (1) Bead shedding resistance

[0057] The test tire was installed on the front left side of the actual vehicle (a 3000cc FR car made in Japan), and it turned right from a straight road into a circular road with a radius of 20m to perform a so-called J-turn. At this time, the internal pressure of the test tire was 0 kPa, and the bead shedding resistance was evaluated at the running speed when the bead shedding occurred. Starting from a driving speed of 25km / h, drive in increments of 5km / h until the bead falls off. The comparative example is taken as 100 for index evaluation. The larger the value, the faster the running speed when bead falling occurs, that is, the better the bead falling resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com