Sheet-like material conveying device

A material conveying device and conveying device technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of reduced conveying efficiency, increased friction, and easy sliding of glass substrates, and achieve improved conveying efficiency and friction powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

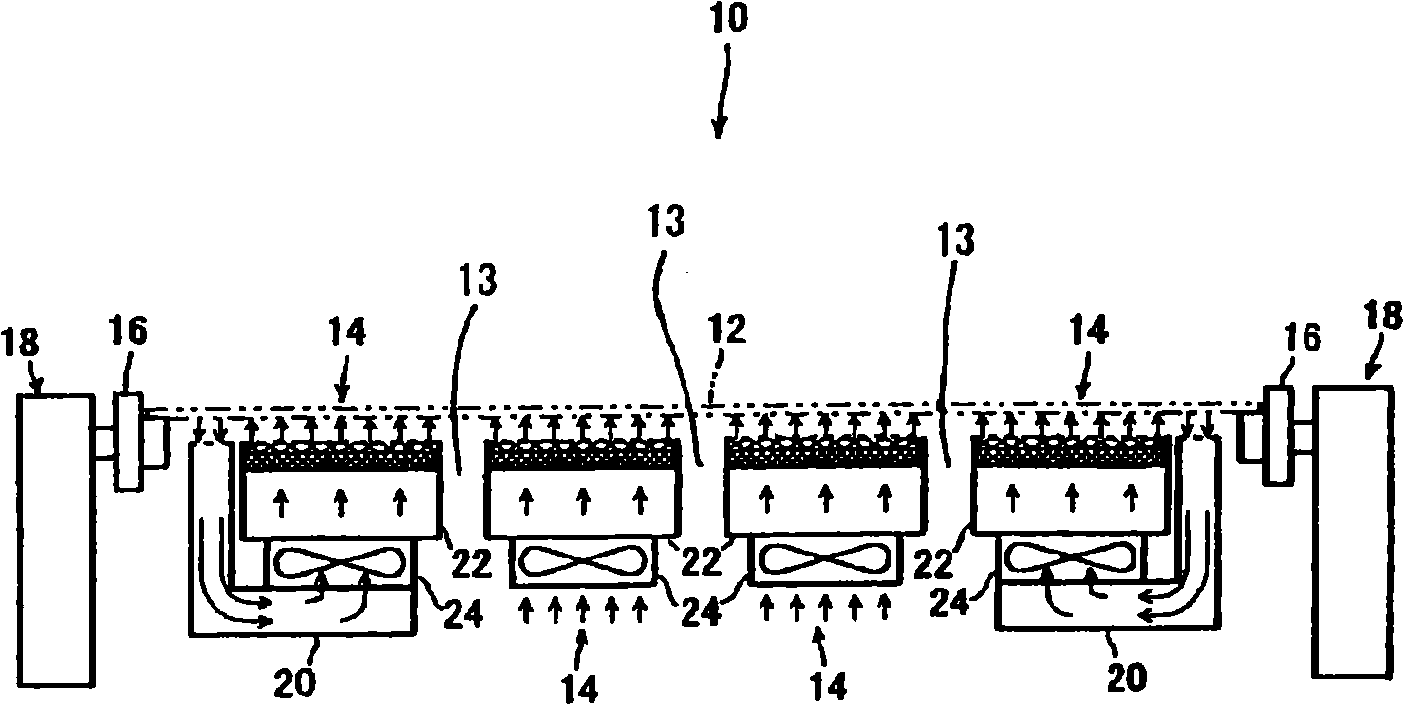

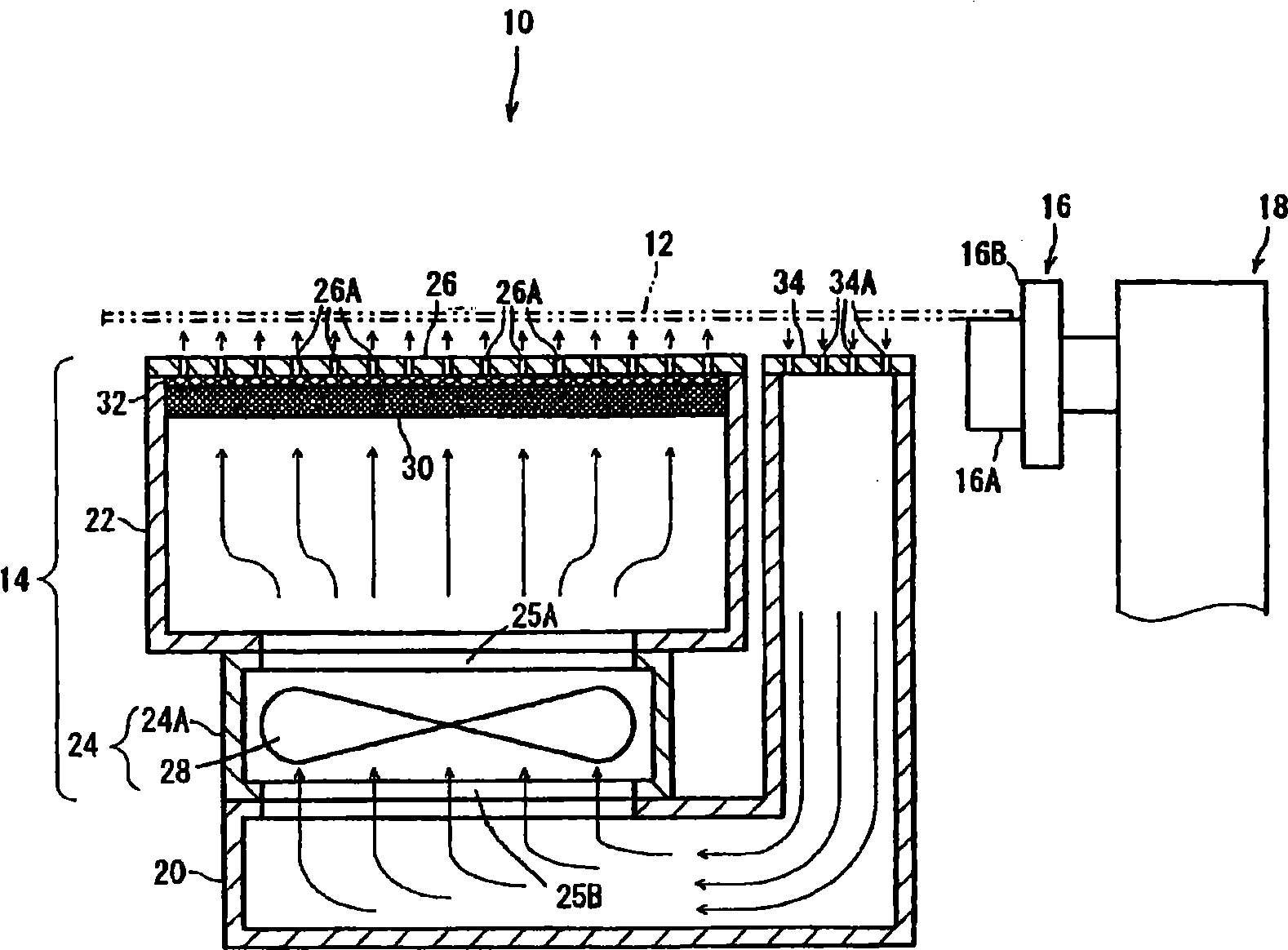

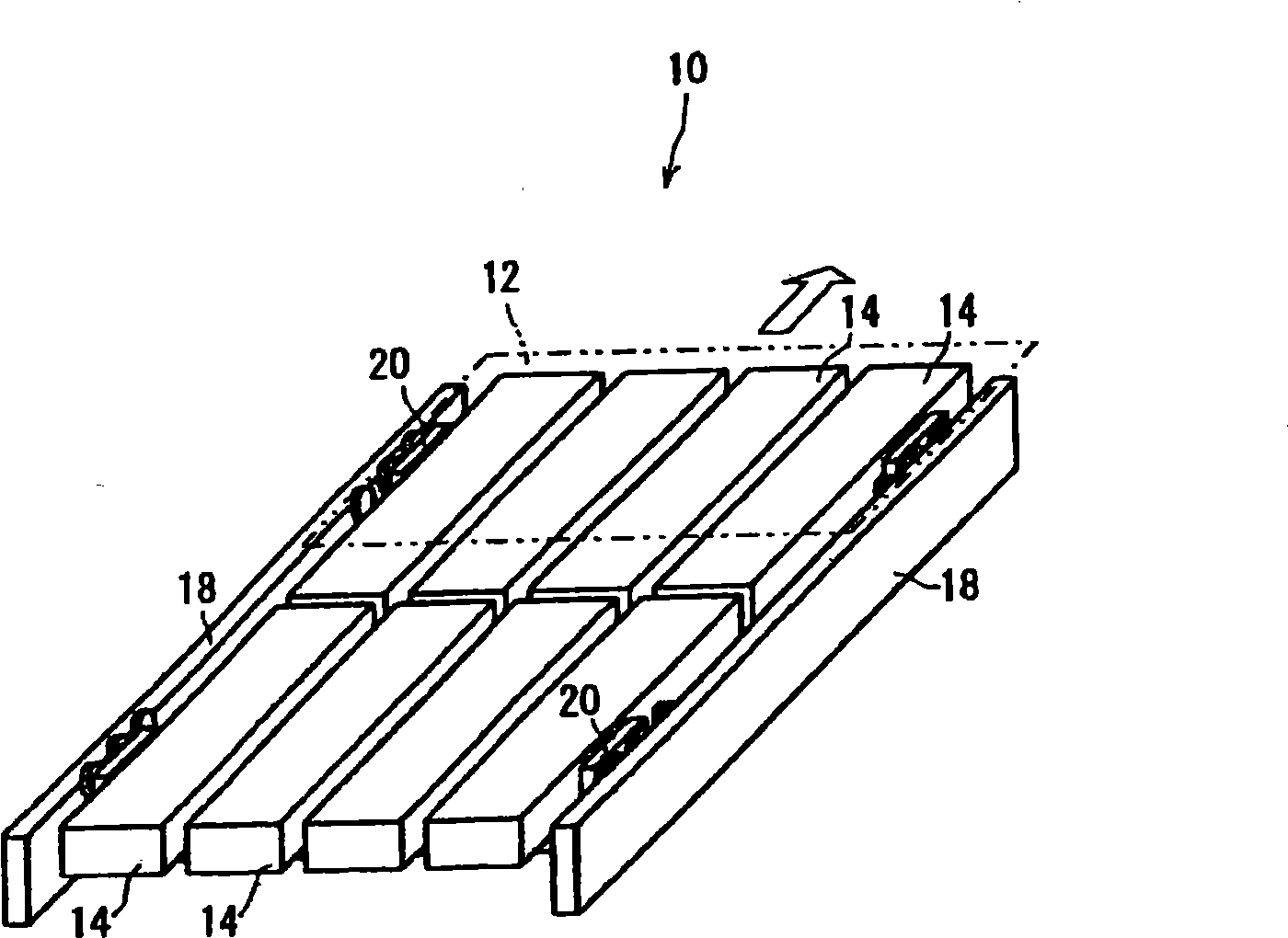

[0045] Such as figure 1 As shown, the sheet-shaped material conveying device 10 according to the first embodiment of the present invention is configured to include: a pneumatic stage unit 14 for non-contact supporting, for example, a glass substrate (thin sheet-shaped material) 12 for a large LCD; and a drive unit 18. There are a plurality of rollers (driving members) 16 which are in contact with the lower surface of the glass substrate 12 and drive the glass substrate 12 in a predetermined conveying direction; the suction unit 20 is arranged in the vicinity of the roller 16 for directing the glass substrate 12 Supply negative pressure on the lower surface and apply force to the substrate 12 in the direction of the roller 16; the pneumatic table unit 14 has a characteristic structure. Furthermore, it is characterized in that the thin-plate-shaped materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com