Sealed terminal device for electric compressor

An electric compressor and a sealed terminal technology, applied in the field of electric compressors, can solve the problems of decreased electrical insulation of terminals, troublesome fixing of metal cages and sealed terminals, difficult installation of sealed terminal devices, etc., and achieve the effect of ensuring sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

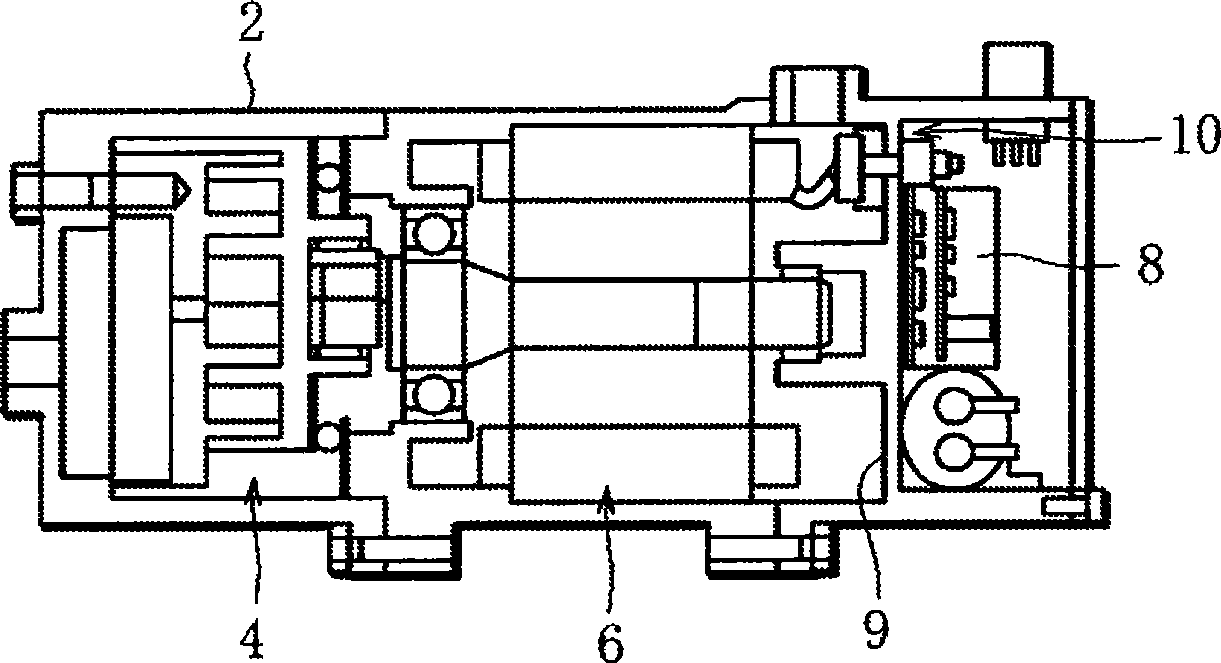

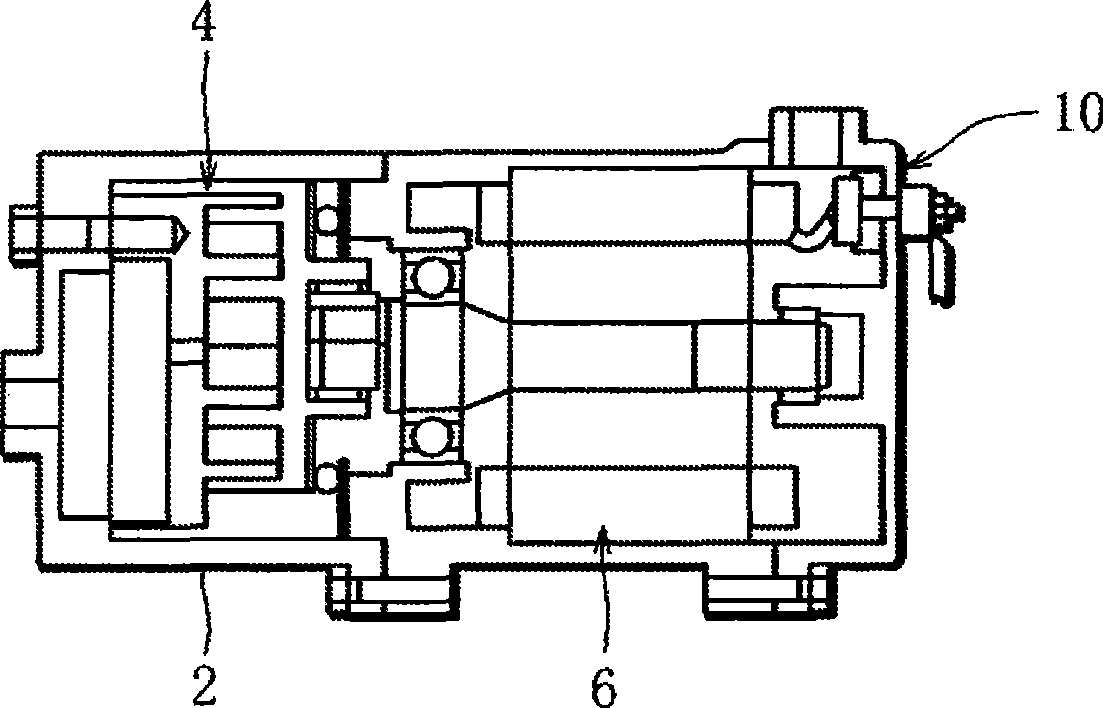

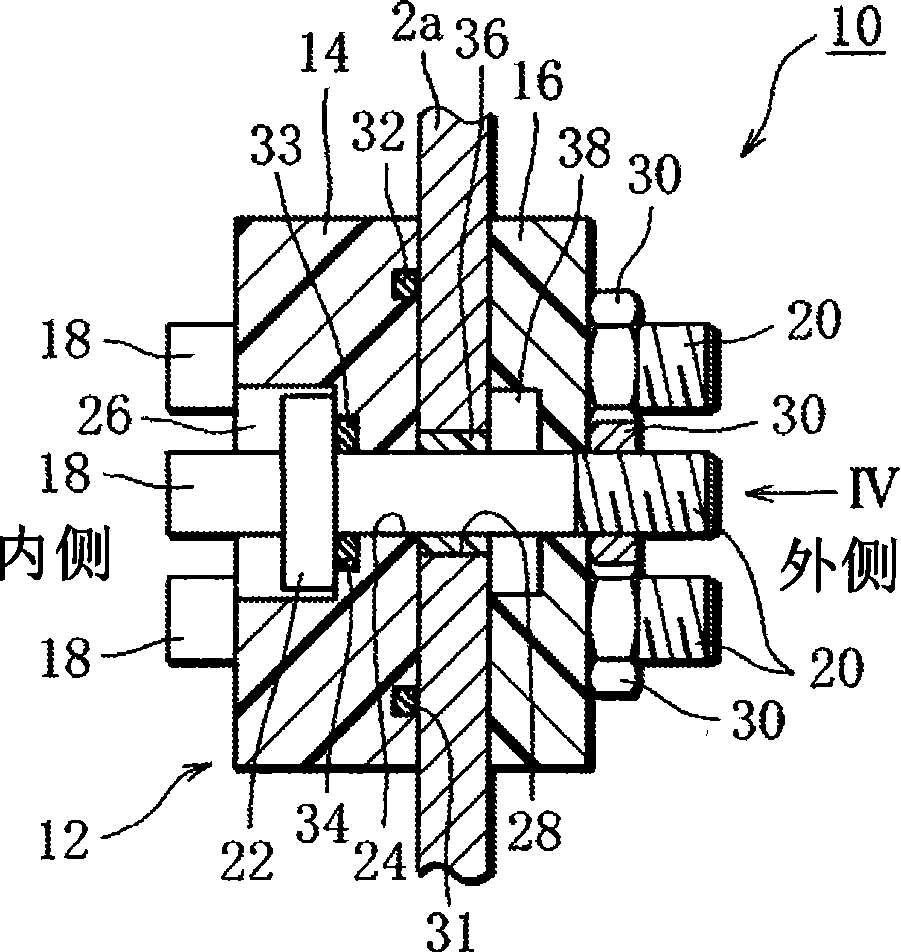

[0026] figure 1 and figure 2 Each shows an electric compressor to which the present invention is applied. These electric compressors all include a metal casing 2 , a compression unit 4 and an electric motor 6 accommodated in the casing 2 . figure 1 and figure 2 The compression unit 4 is represented as a scroll unit.

[0027] figure 1 The compressor further includes a power supply control board 8 accommodated in the casing 2 . The control board 8 has an inverter and controls the power supply to the electric motor 6 and the driving of the electric motor 6 . Specifically, in figure 1 The housing 2 is provided with a partition wall 9 that partitions the housing 2 into a chamber for accommodating the compression unit 4 and the electric motor 6 and a chamber for accommodating the control board 8 .

[0028] on the other hand, figure 2 compressor with figure 1 The difference of the compressor is that there is no above-mentioned partition wall 9. However, figure 1 and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com