Large-scale crane hook set

A technology for cranes and hook sets, applied in the field of hook sets, which can solve problems such as processing and installation difficulties, hook set deflection, four-claw hook size and self-weight, etc., and achieve simple processing and installation, and reduce friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

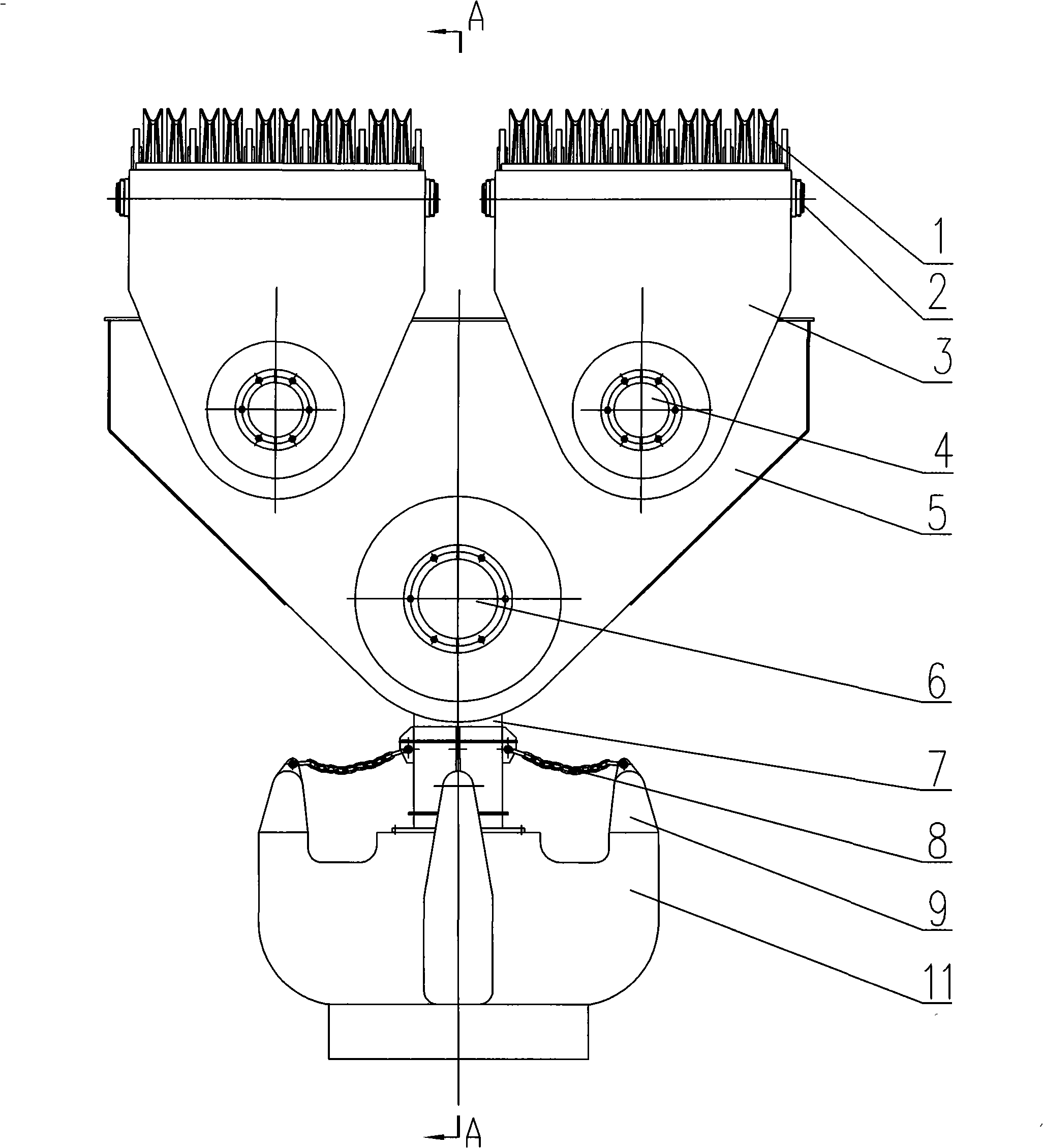

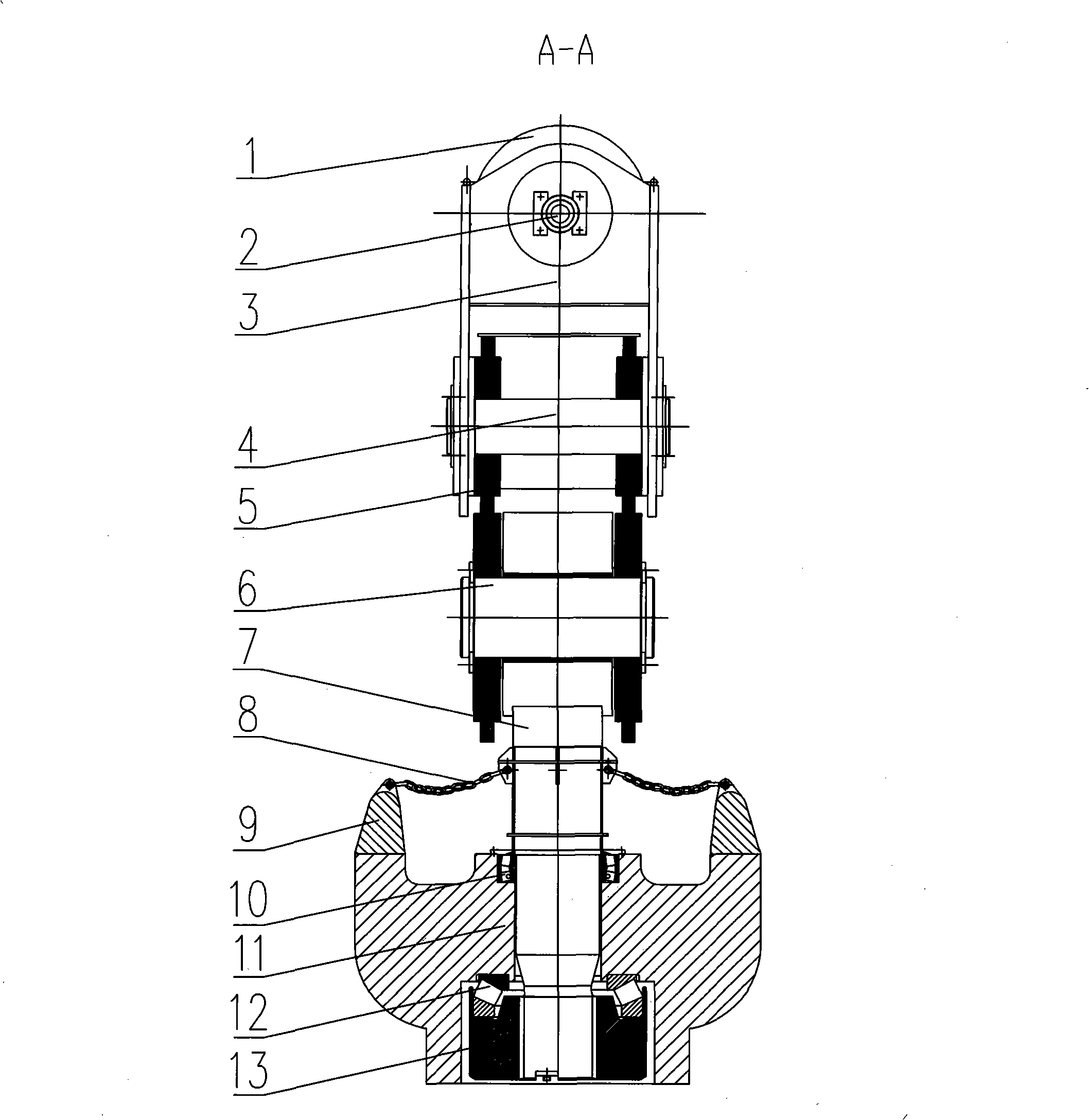

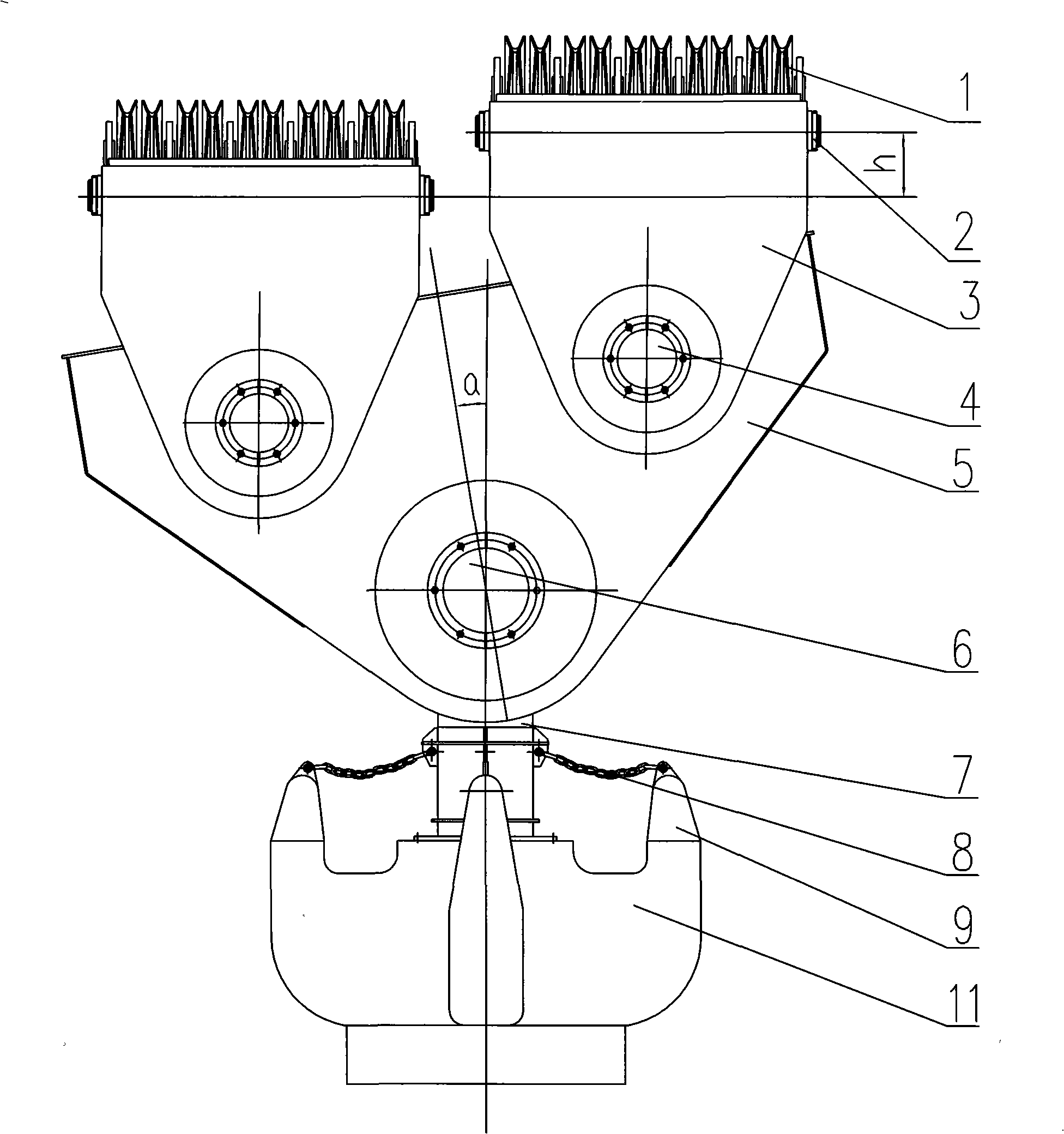

[0018] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-3 As shown, a large crane hook group mainly includes a pulley 1, a pulley shaft 2, a spherical roller bearing 10, a spherical roller thrust bearing 12, a hook nut 13, an anti-off chain 8, and also includes a pulley bracket 3, a hinge shaft I 4, balance beam 5, hinge shaft II 6, hook shaft 7, hook body upper part 9, hook body 11, there are two pulley shafts 2, and the pulley 1 is divided into two groups, each group is respectively connected with A pulley bracket 3 is connected to form two pulley blocks; the pulley bracket 3 is connected with the balance beam 5 through the hinge shaft I 4 respectively, and the balance beam 5 is connected with the hook shaft 7 through the hinge shaft II 6, and the bottom of the hook shaft 7 Connected with the hook nut 13 by threads, the upper part of the hook nut 13 is equipped with a spherical roller thrust bearing 12; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com