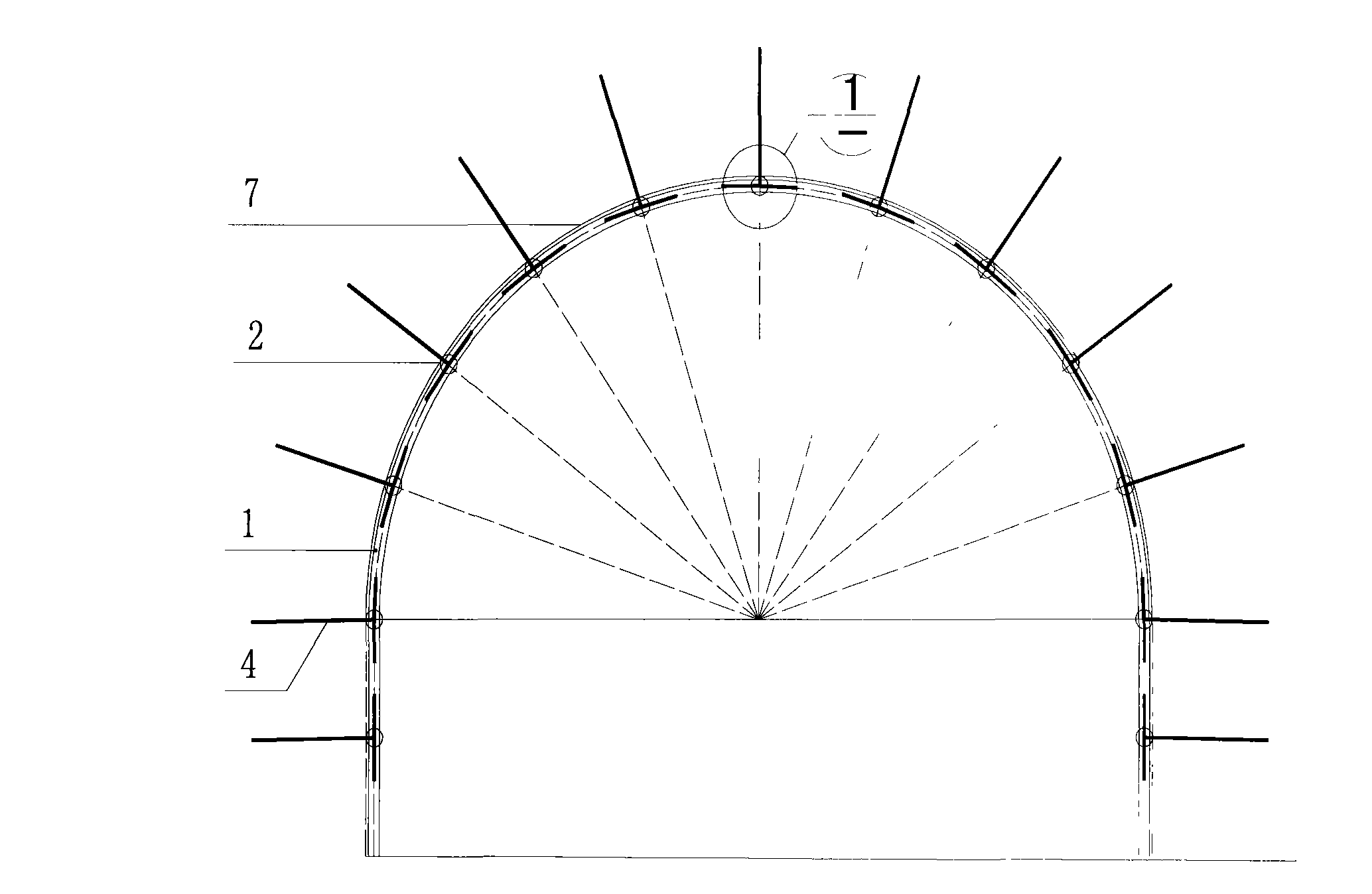

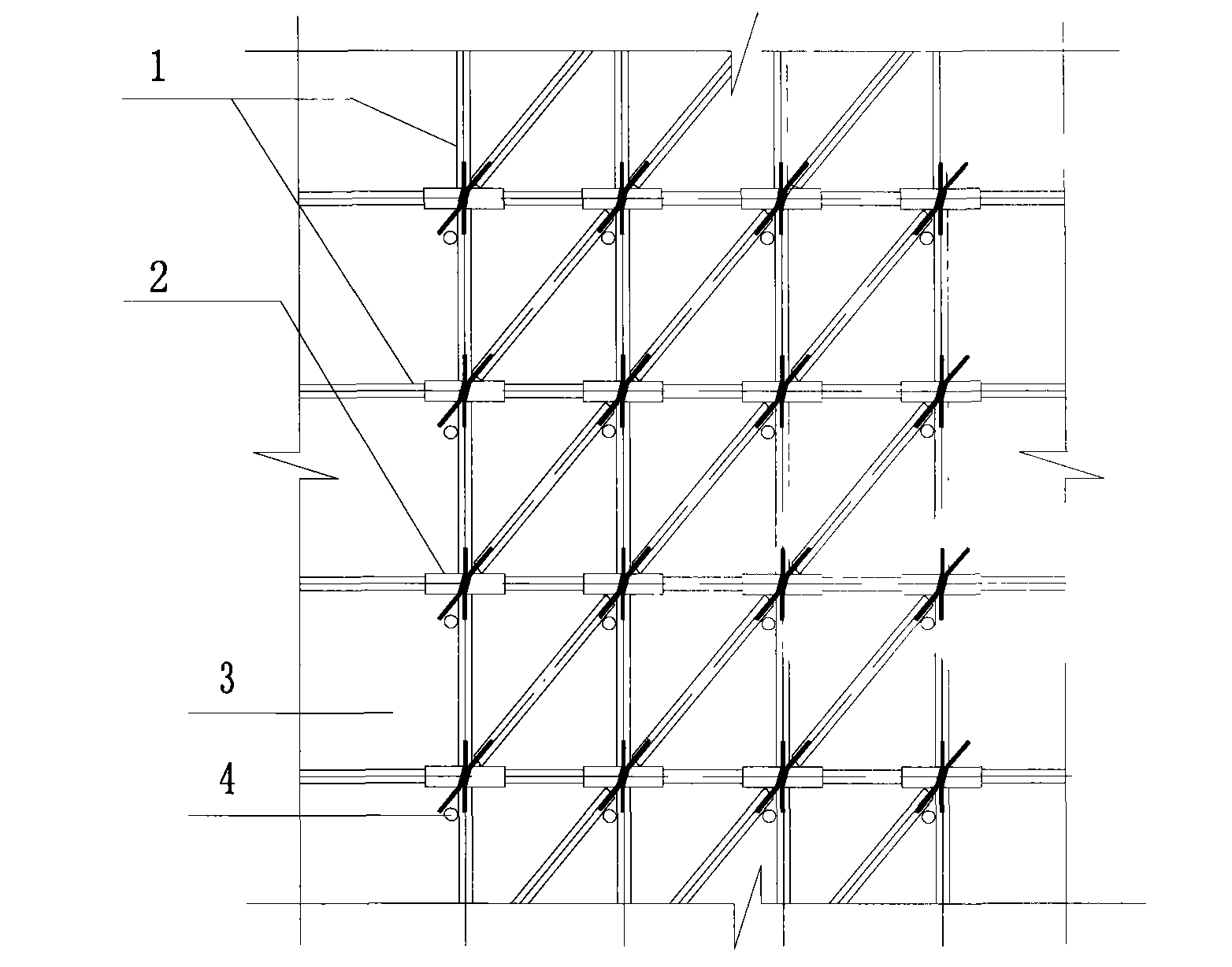

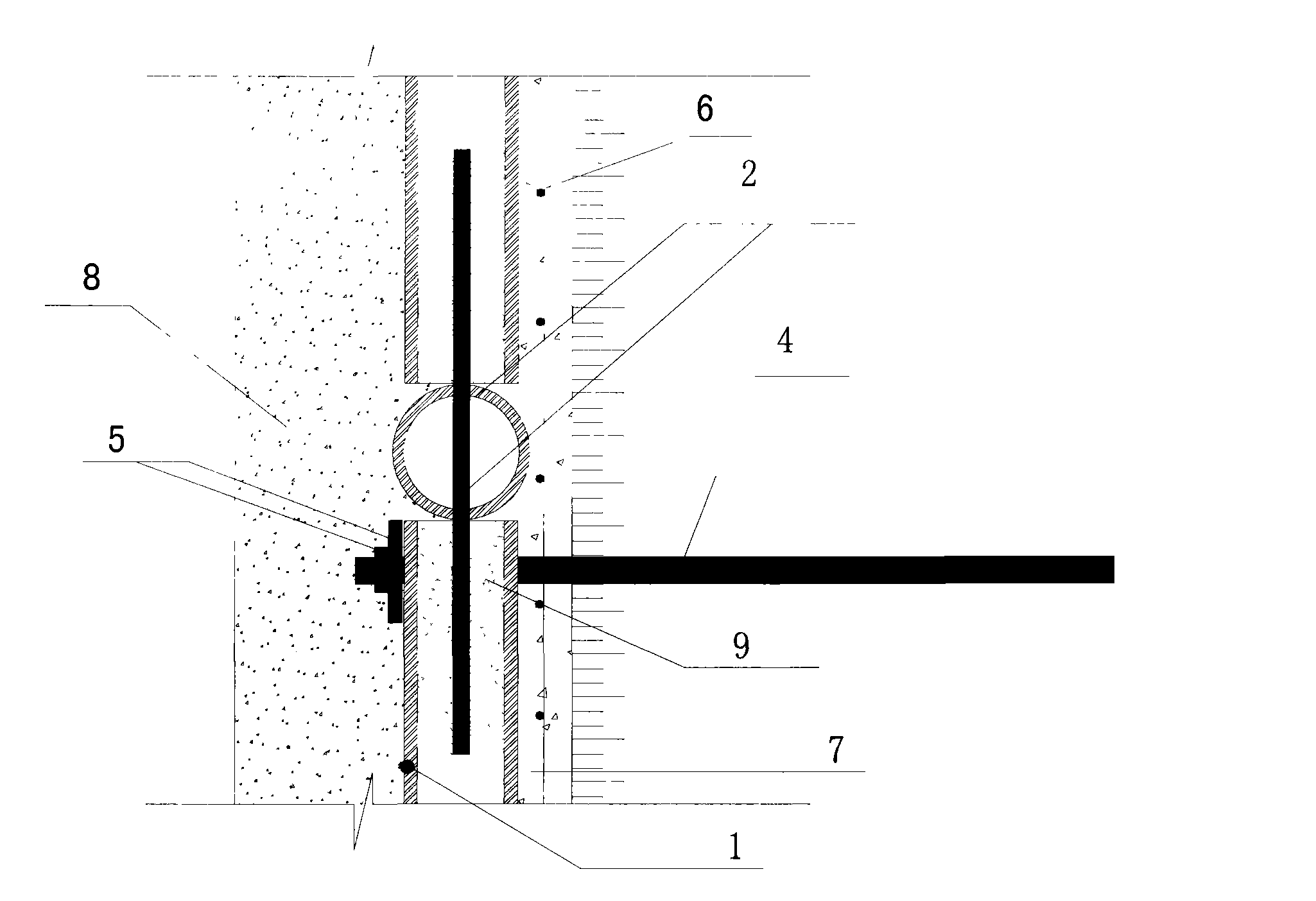

Combined support device of network frame and concrete and application method in underground engineering

A combined support and concrete technology, which is applied in underground chambers, earthwork drilling, shaft equipment, etc., can solve the problems that steel supports cannot be installed, the construction period is prolonged, and the price is expensive, so that the labor intensity of workers is low and the cost of support is low. The effect of low cost and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] When the stratum is relatively stable, it is sufficient to use the grid frame 3 and fill the backboard or bagged concrete behind the frame.

Embodiment 2

[0038] When the stratum is not stable, use grid frame 3 and shotcrete 8, hang a layer of steel mesh between the grid frame 3 and the surrounding rock, fill it with backboard or mold bag, shotcrete 7, and then fill the inner and outer sides of grid frame 3 A layer of shotcrete 8 is sprayed to form the joint support of grid frame and concrete.

Embodiment 3

[0040] When the network frame 3 is connected by bolted spherical joints, it can be connected according to the structural connection method of the prior art, and the others are carried out according to Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com