Strong corrosivity medium phase interface measurement method

A phase interface and flow technology, applied in the direction of displaying the liquid level indicator through pressure measurement, can solve the problems of difficult to ensure effective use for a long time, corrosion, and high cost of the instrument, achieving low cost, simple measurement method, Apply a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

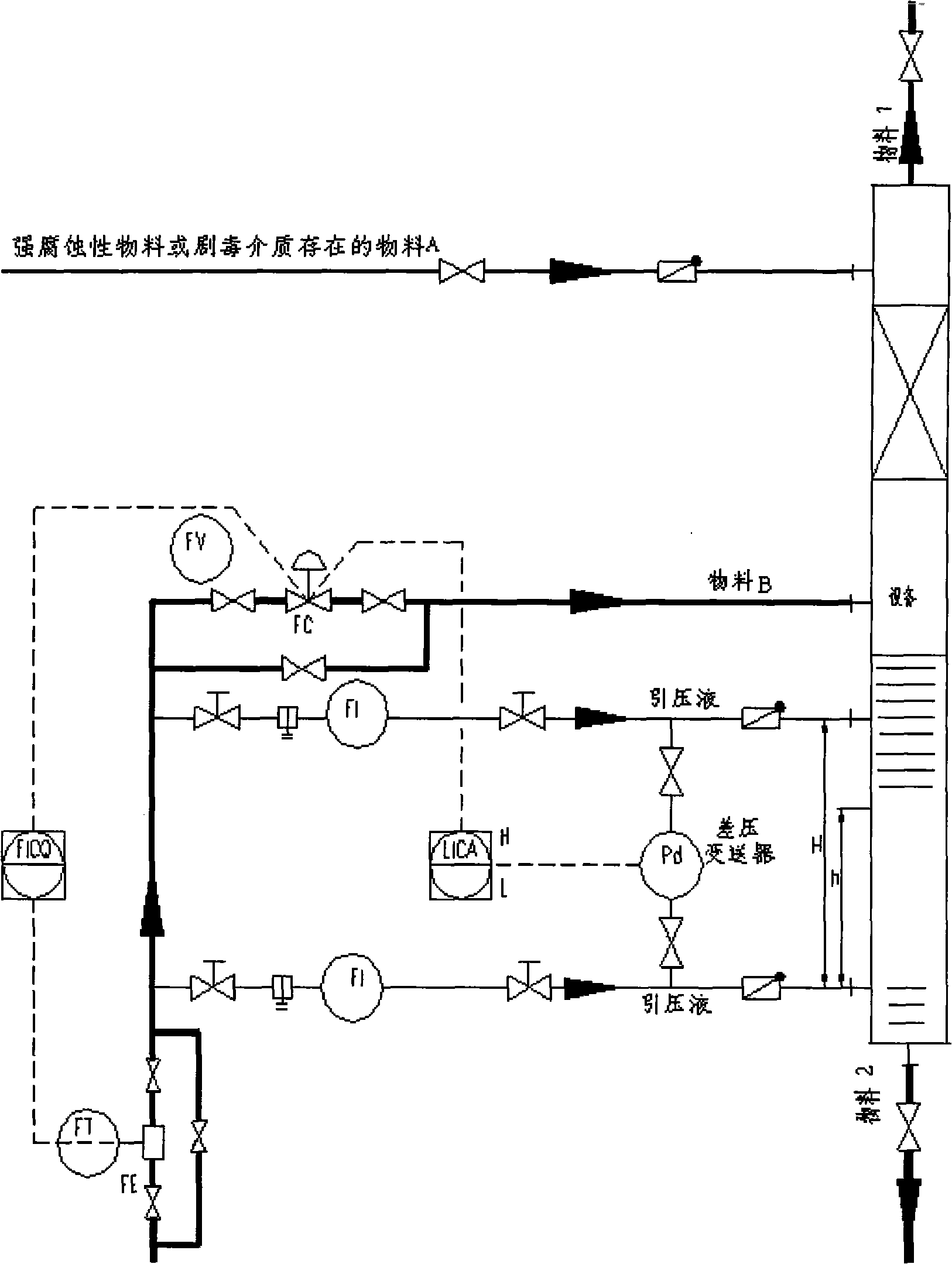

[0026] The mensuration of embodiment 1 two-phase interface

[0027] The method of the present invention is used to measure the hydrofluoric acid in the upper phase and the phase interface of Freon in the lower phase.

[0028] Using water as the pressure fluid, open the pressure port on the side wall of the equipment, the upper pressure port is connected with the strong acid of the inorganic mixture in the upper layer, and the lower pressure port is connected with the organic mixture, and the relative height of the upper and lower pressure ports is H; ensure the pressure The liquid flows into the device from the upper and lower pressure ports at a certain flow rate (if the pressure of the pressure liquid is lower than the internal pressure of the equipment, a booster pump is required to pressurize the pressure liquid) into the equipment from the upper and lower pressure ports (it is enough to ensure a slight positive pressure at the pressure port) , in order to ensure and measu...

Embodiment 2 3

[0034] The mensuration of embodiment 2 three-phase interface

[0035] The method of the present invention is used to measure that the upper layer is hydrocyanic acid, the middle layer is difluorochloromethane, and the lower layer is CCl 4 Use the medium that is easy to separate from various materials in the equipment: water is used as the pressure fluid, and a pressure port is opened on the side wall of the equipment. The upper pressure port is connected with hydrocyanic acid, and the middle pressure port is connected with difluoro Chloromethane is connected, and the lower pressure port is connected with CCl 4 The relative height between the upper and middle pressure introduction ports is H1, and the relative height between the middle and lower pressure introduction ports is H2; ensure that the pressure induction fluid flows into the equipment from the upper, middle and lower pressure introduction ports at the same flow rate, and the difference The pressure sensors of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com