Rotatable water-cooled cable

A water-cooled cable, rotary technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems that the installation bolts are difficult to fasten to the pry, cannot be rotated with them, and the inner core of the cable is twisted, etc. The effect of avoiding sprains and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further elaborated below in conjunction with preferred embodiment:

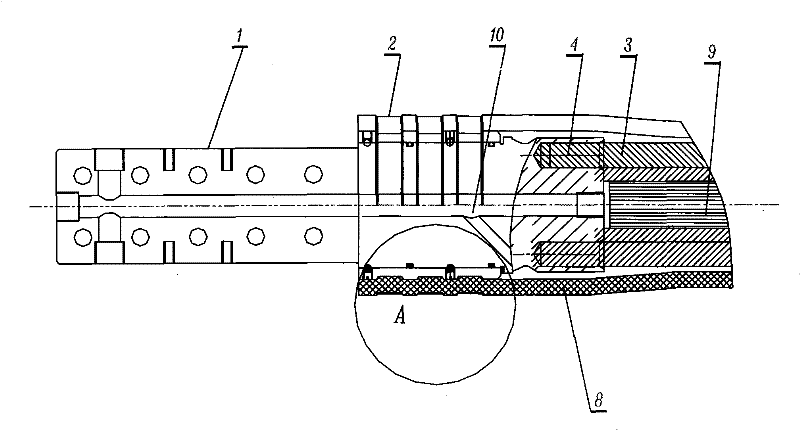

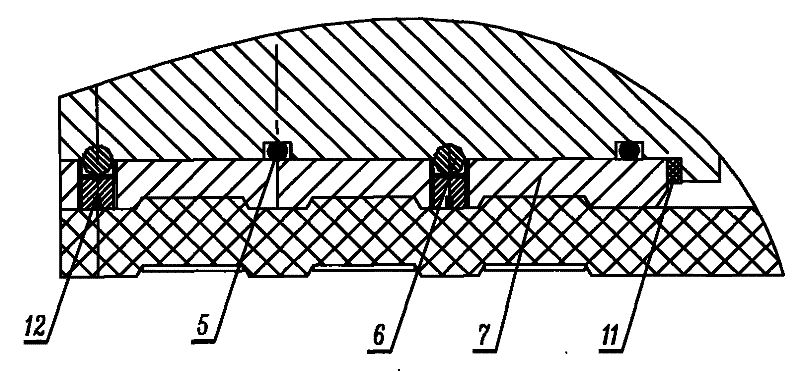

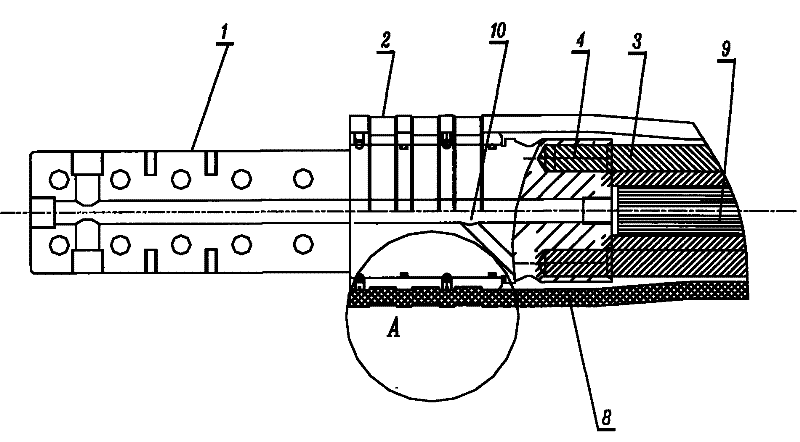

[0020] Such as figure 1 with figure 2 As shown, the rotatable water-cooled cable of the present invention includes copper joint 1, pipe ferrule 2, copper strand 3, sealing ring 5, 11, ball 6, rotating sleeve 7, rubber tube 8 and differential spring 9, Among them: the ball 6 is embedded in the rolling groove on the outer edge of the copper joint 1, and then the grooved screw 12 is used to limit the position in the groove, and the rotating sleeve 7 is set on the outer edge of the cylindrical part of the copper joint 1 through the ball 6; the sealing ring 5 , 11 are located between the groove of the copper joint 1 and the rotating sleeve 7, the differential spring 9 is located at the center of the multi-strand copper strand 3, so that the copper strand 3 is wound along its outer edge, and the copper strand 3 is inserted into the copper joint 1 interface 4 inside. The outer edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com