Method and device for automatically sorting regular objects according to request of order

An automatic sorting and rule-based technology, applied to storage devices, unstacking of objects, conveyor objects, etc., can solve problems such as high labor intensity, heavy workload, structural problems, etc., to improve the level of automation, reduce labor intensity, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

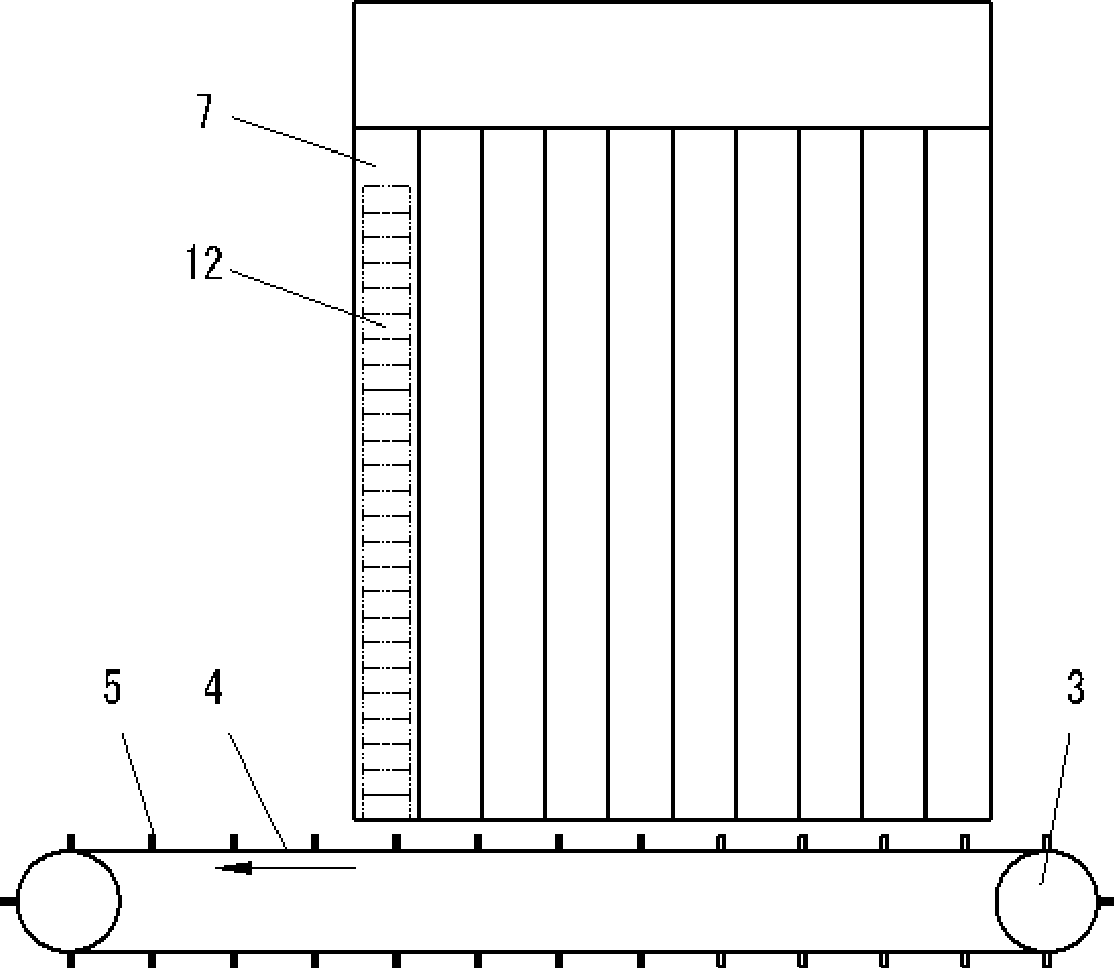

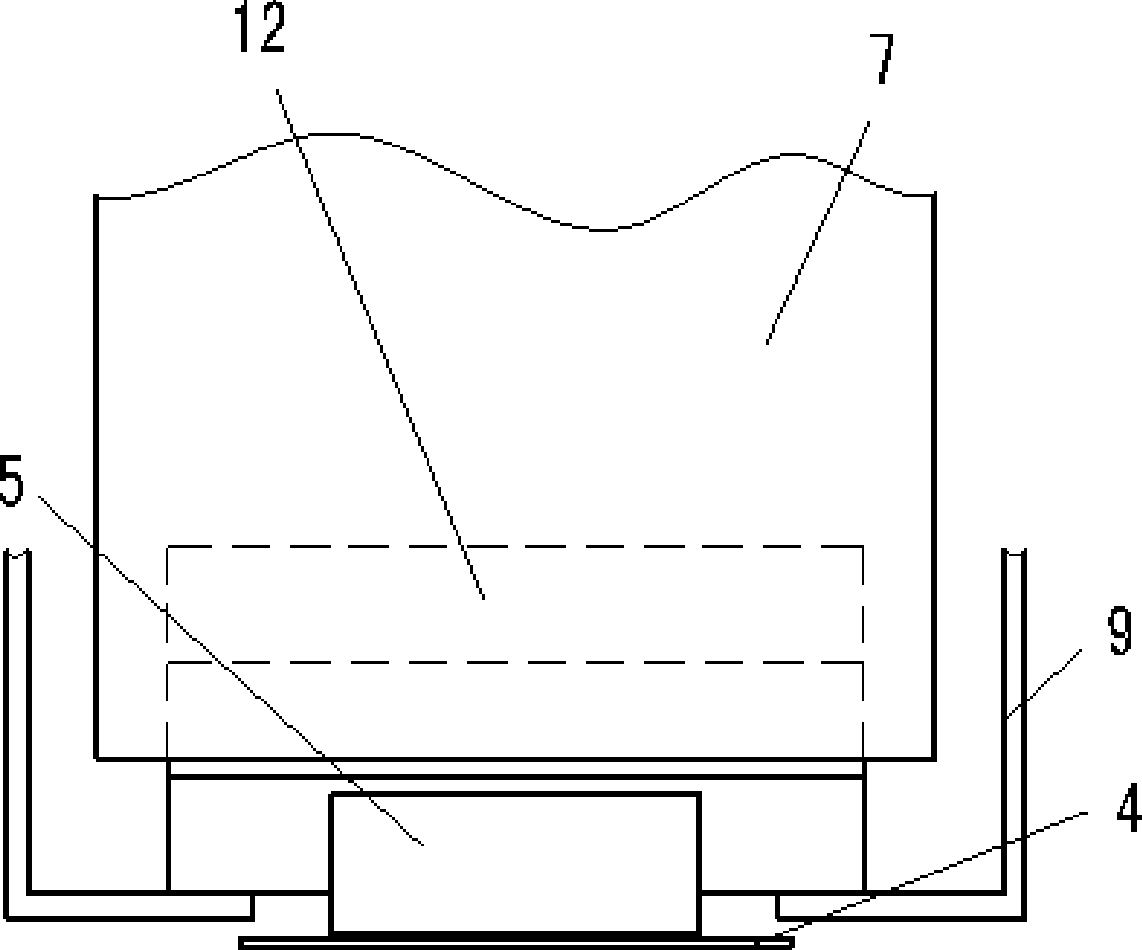

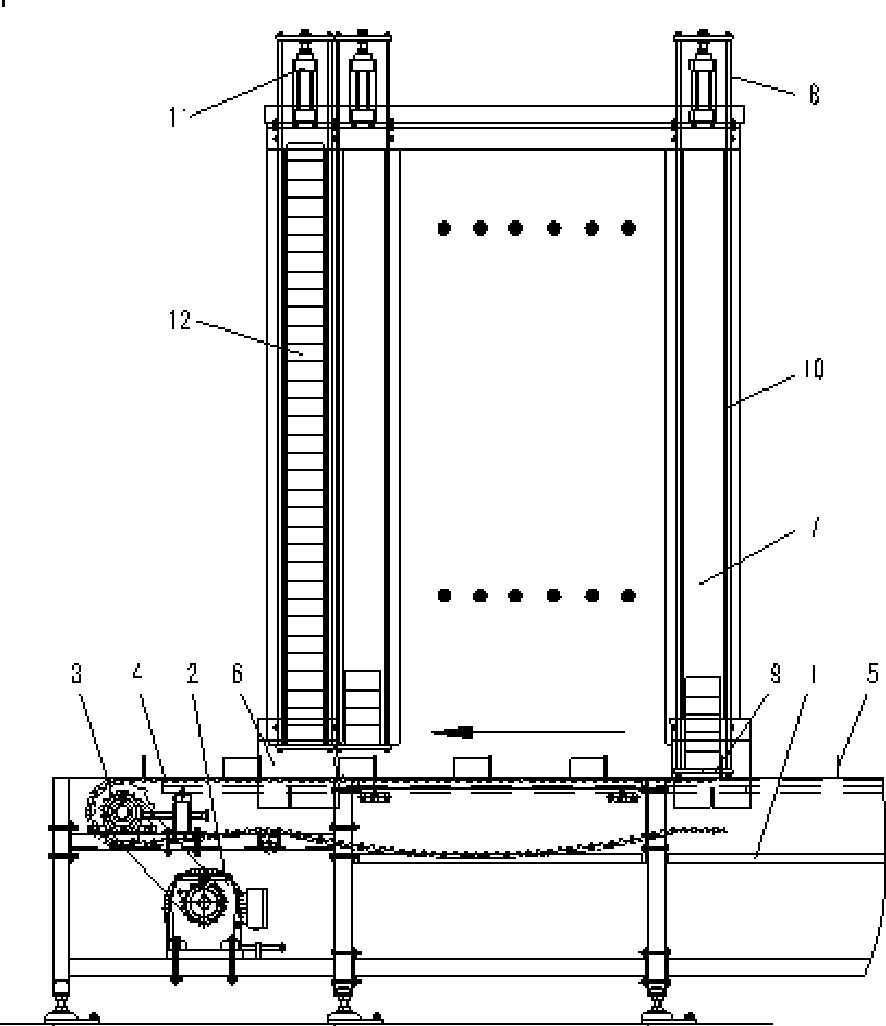

[0017] Embodiments of the present invention: the method for automatically sorting regular objects according to order requirements of the present invention is as follows: figure 1 and figure 2 shown. The method is to store regular objects 12 in different storage bins 7 according to different brands. The lower end of the storage bins is open, and the regular objects can slide out from the opening at the lower end of the storage bins. Driven by the lifting mechanism, the board can move up and down to put down or lift the regular objects. There is a conveyor belt 4 under the storage bin. During the operation of the conveyor belt, the push plate 5 on the conveyor belt Push out the laid-down regular objects one by one; when the regular objects of this brand are sorted, the lifting plate lifts up the regular objects of this brand, so that the push plate on the conveyor belt cannot push the regular objects of this brand, and at the same time another brand The lifting plate on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com