High tension thick steel plate with excellent toughness at welding heat affected zone

A heat-affected zone and high-tension technology, which is applied in the field of high-tensile thick steel plates for welding, can solve problems such as promoting coarsening of the structure, prolonged high temperature retention time, and reduction of HAZ toughness, achieving excellent HAZ toughness, and realizing microstructure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

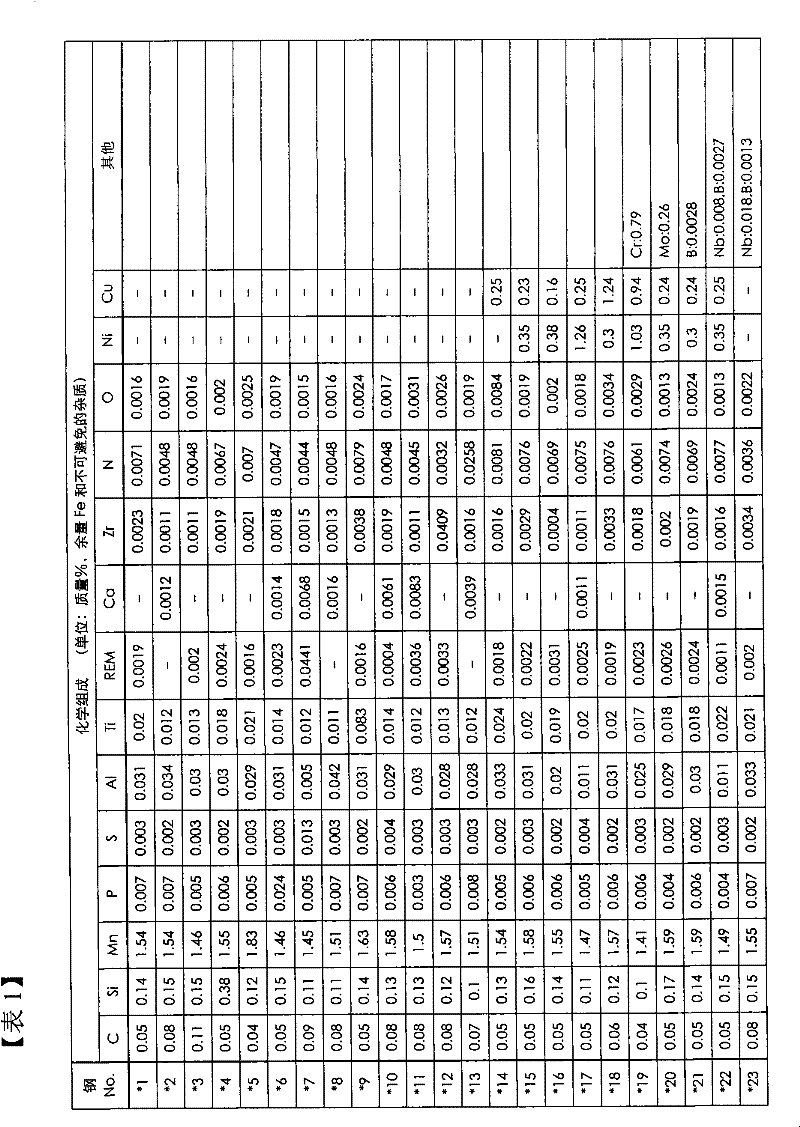

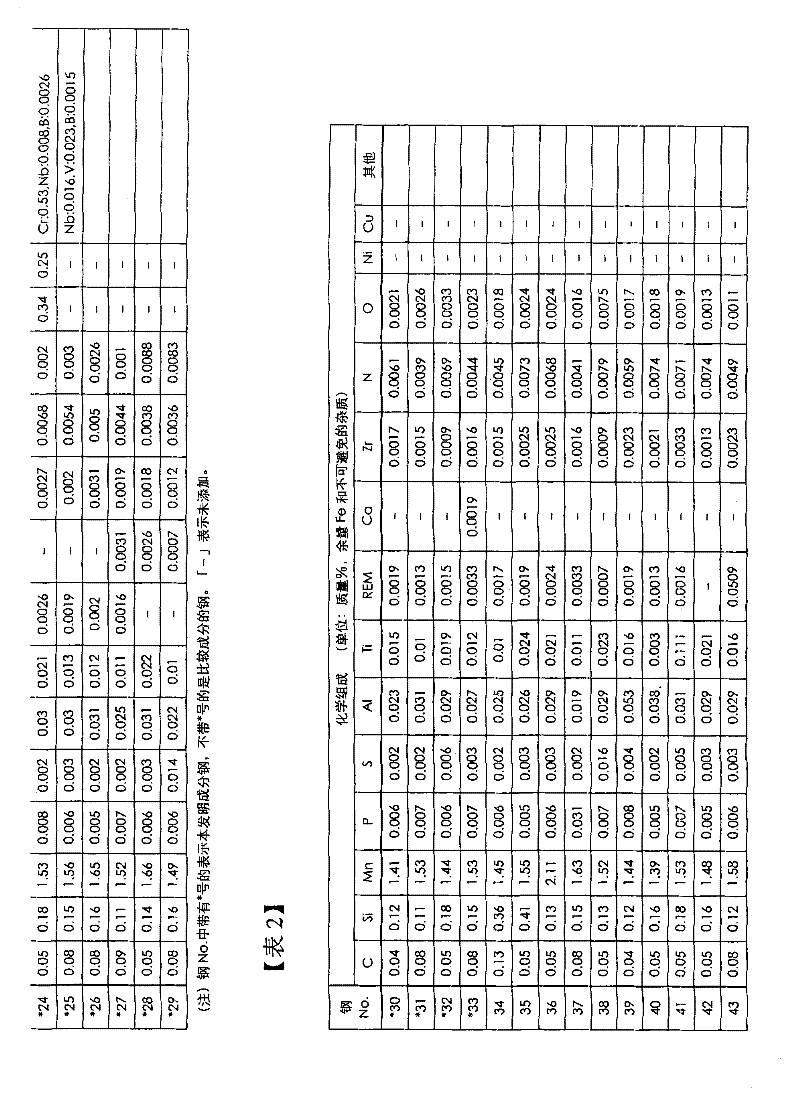

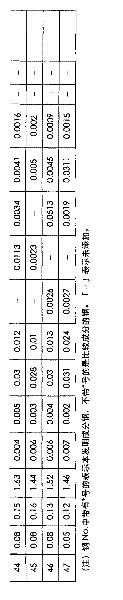

Examples

Embodiment Construction

[0036] Hereinafter, the high-tensile steel sheet for welding according to the embodiment of the present invention will first be described in detail from the structural conditions thereof.

[0037] In general, to suppress the coarsening of γ grains, it is necessary to disperse fine inclusion particles at a high density, but as the particle size increases, the number density of inclusion particles decreases, and the coarsening of γ grains cannot be suppressed. Therefore, the present inventors obtained the particle size and number density of inclusions that can obtain a sufficient effect of suppressing the coarsening of γ grains through experiments, and found that oxides having a circle-equivalent diameter smaller than 2 μm were dispersed up to 500 inclusions / mm 2 Above, coarsening of γ grains is suppressed. If the equivalent circle diameter is smaller than 2μm, the ratio of oxides is 500 / mm 2 If it is small, the desired effect of suppressing the coarsening of γ grains cannot be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com