Water-gas mixing jet apparatus for pile sinking

A technology of water-air mixing and jet flow, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve problems such as low work efficiency and weak scouring force, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

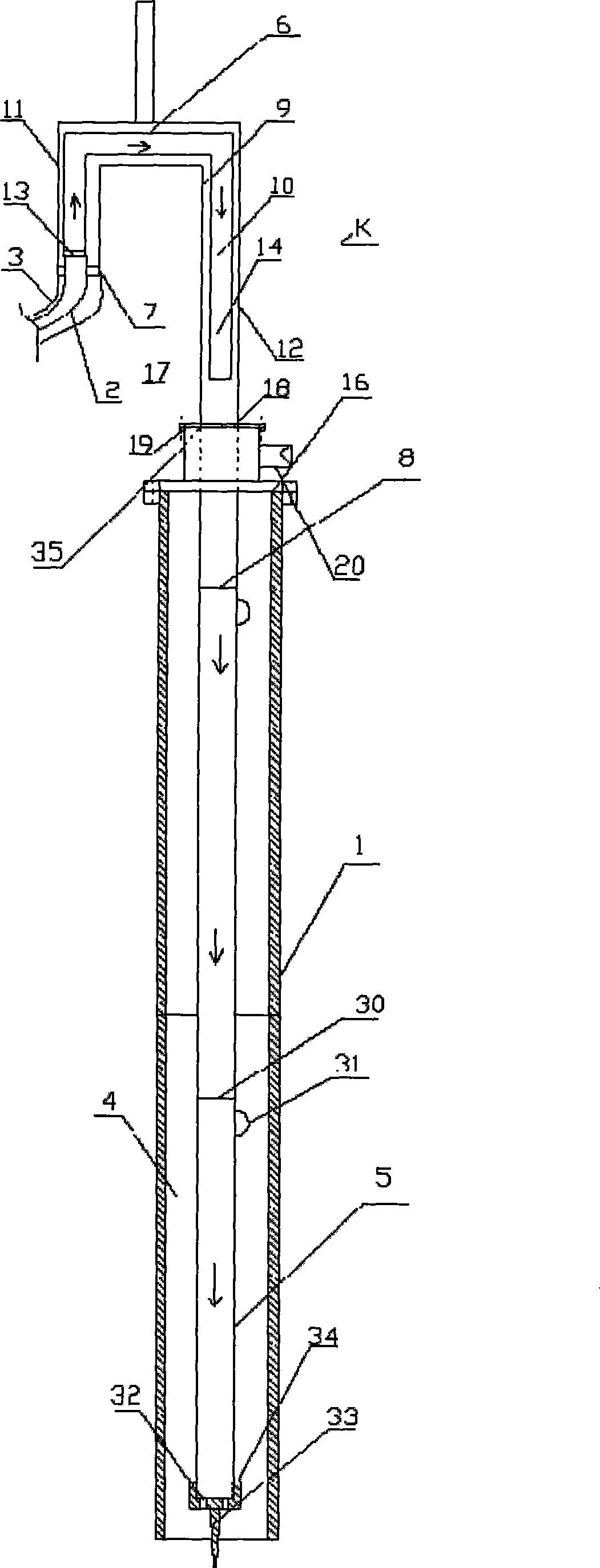

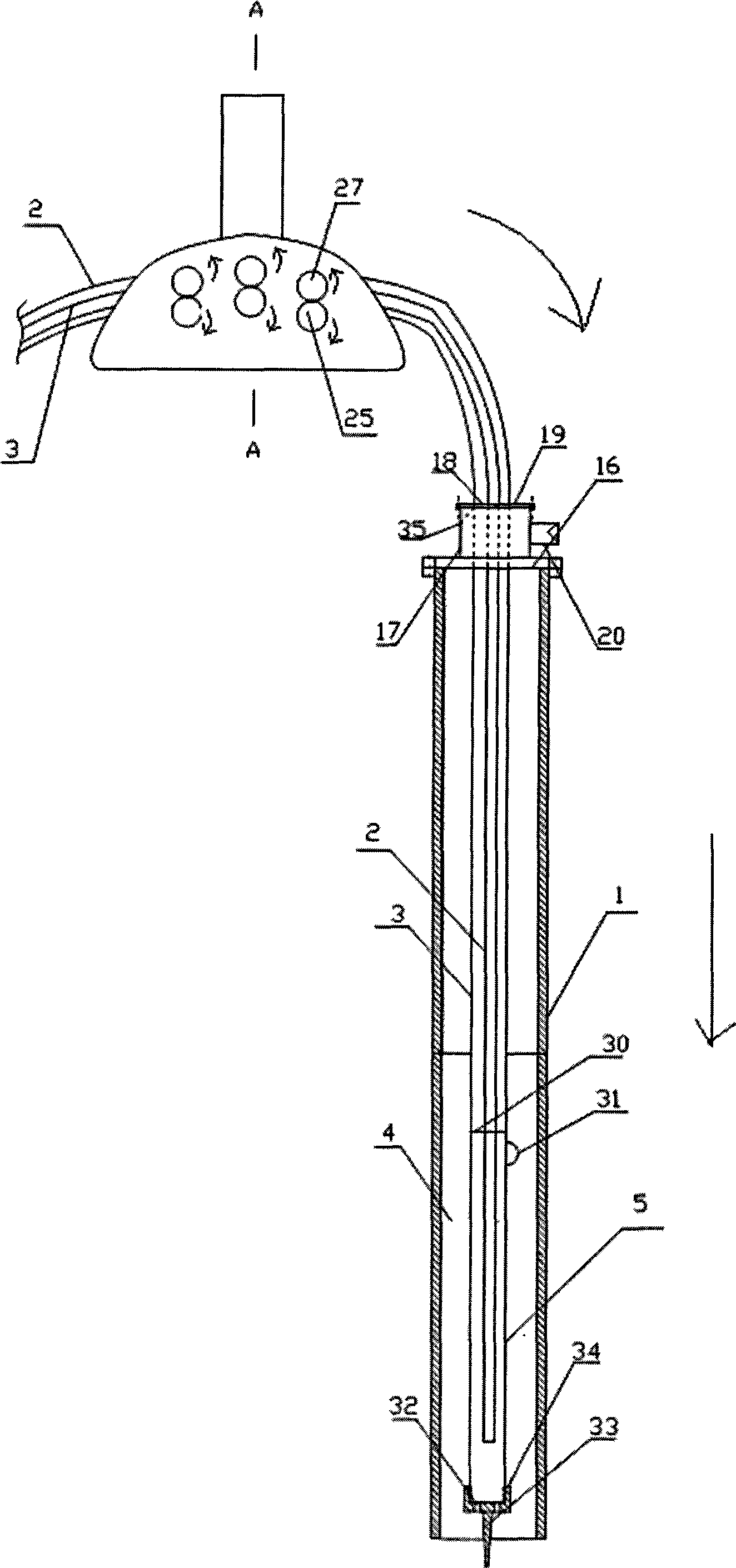

[0011] The present invention includes a pile body 1, a high-pressure water pipe 2 and a high-pressure air pipe 3, and is characterized in that: the high-pressure water pipe and the high-pressure air pipe are incorporated into a high-pressure jet mixing pipe 5 extending to the bottom of the pile cavity 4 .

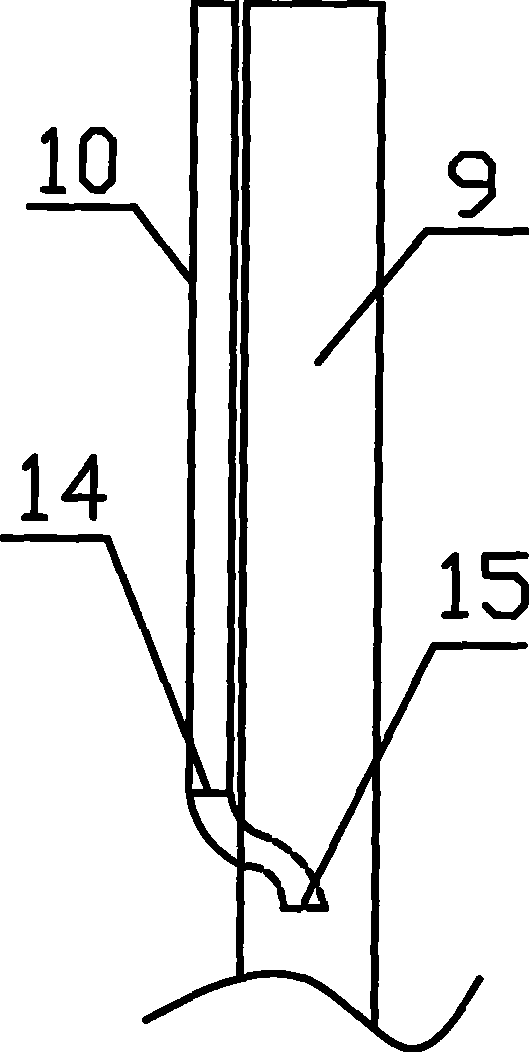

[0012] The structural feature of Embodiment 1 of the present invention is that the high-pressure water pipe and the high-pressure air pipe are connected to the high-pressure jet mixing pipe extending to the bottom of the inner cavity of the pile through the mixer 6 suspended at a high place, and the mixer is connected to the high-pressure water pipe by the inlet 7 The outlet 8 is connected to the high-pressure jet mixing pipe, and the main elbow 9 and the curved air pipe 10 are formed. The main elbow is composed of a curved water inlet pipe section 11 and a vertical water outlet pipe section 12. The inlet of the curved air pipe The end 13 is docked with the high-pressure air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com