Surface printing skirting board, printing apparatus and method thereof

A skirting and printing technology, which is applied in printing, printing machines, rotary printing machines, etc., can solve the problems of stickers or patches being easily warped, complicated processing procedures, and affecting the appearance, so as to improve production efficiency and reduce production costs , printing device and method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the accompanying drawings.

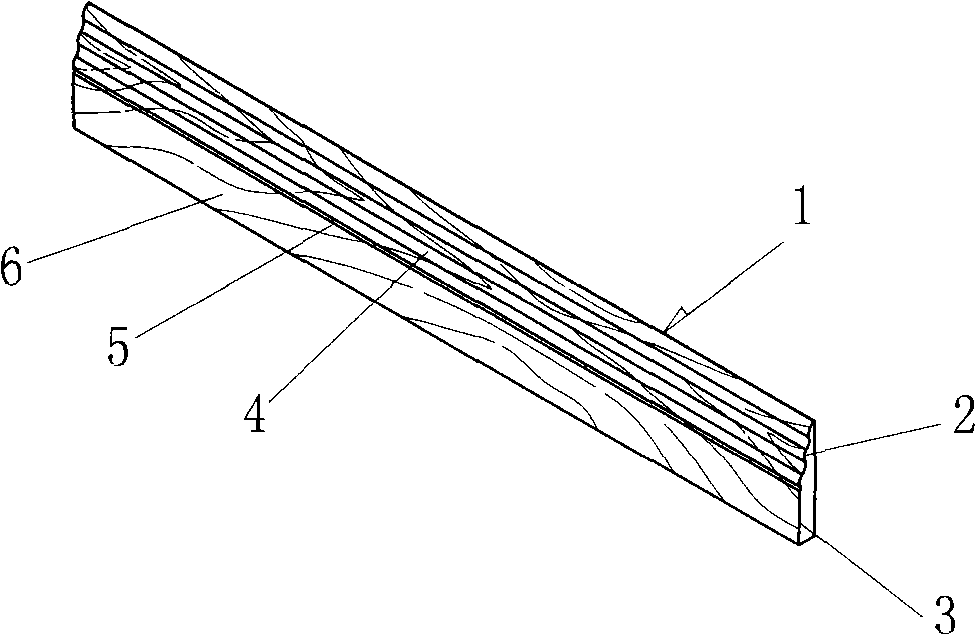

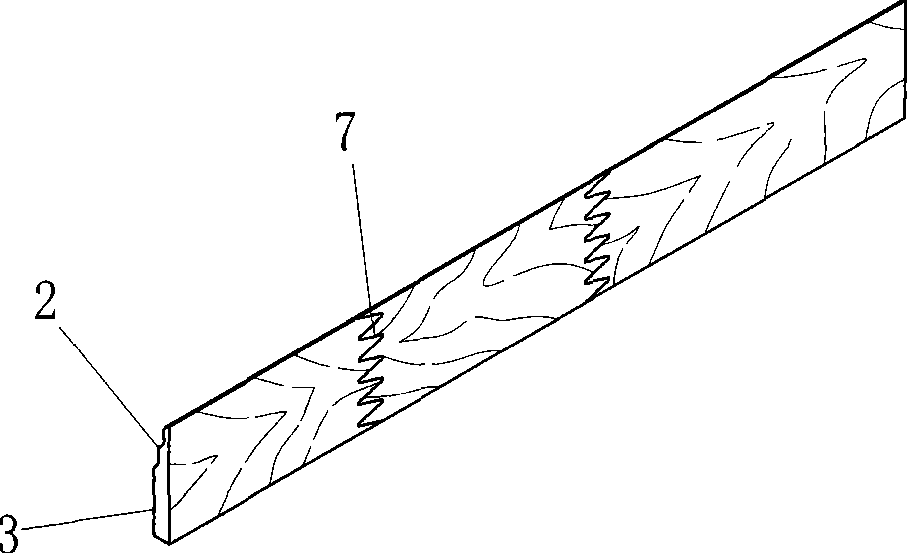

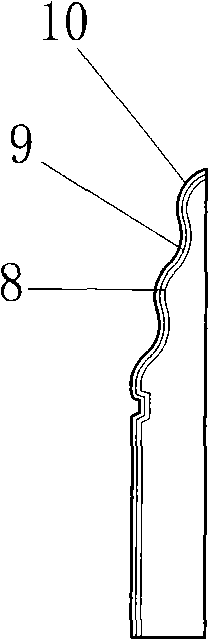

[0031] The substrate 1 of the surface printed skirting board of this embodiment is a rectangular strip substrate with an oblique cut surface, that is, the lower part of the substrate 1 is a vertical flat part 3, and the upper part is a front inclined cut surface 2, and on the front inclined cut surface 2 Concave-convex horizontal decorative strips 4 and fixing nail grooves 5 are formed, and the front of the substrate 1 is directly coated with a decorative surface layer 6 composed of a base color layer 8 , a decorative pattern layer 9 and a transparent paint protective layer 10 . In order to save wood, the substrate 1 is grafted with short-cut materials, and the front seam 7 is finally covered by the decorative surface layer 6 without affecting the appearance.

[0032] The above-mentioned surface printing and printing equipment of the skirting board substrate with a bevel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com