Automatic weighing transmission quality control system for powder compacting product

A technology of automatic weighing and conveying quality. It is used in automatic feeding/discharging weighing equipment, conveyor control devices, weighing and other directions. It can solve the problem of high human resource costs, automatic screening of waste products, and low sampling rate. problems, to achieve the effect of improving product quality, facilitating automated management, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

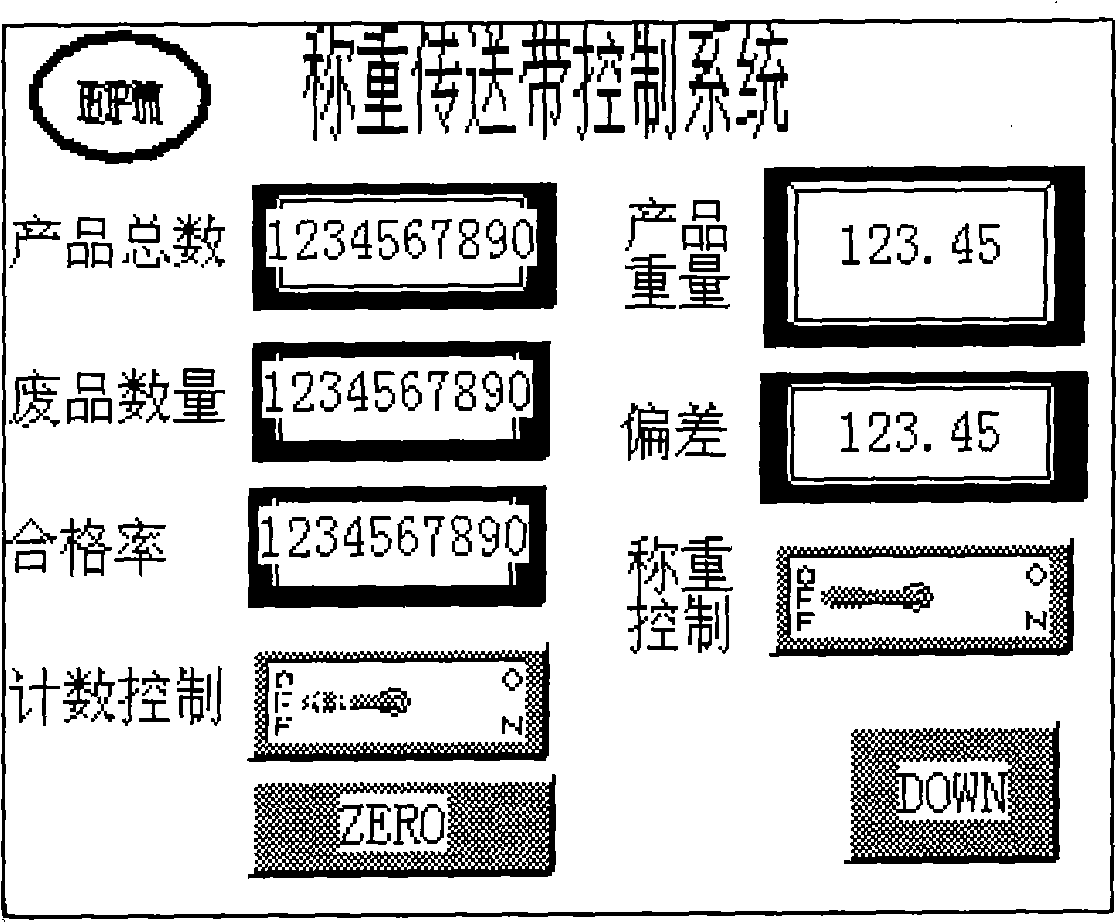

[0031] Refer to attached figure 1 , figure 1Control system Touch screen control screen 1 is the main monitoring screen of the system, mainly used for production statistics display and product weighing display. The monitoring data include: total number of products, quantity of rejected products, pass rate, product weight, deviation; control buttons include: weighing control ON / OFF, counting control ON / OFF, clearing ZERO.

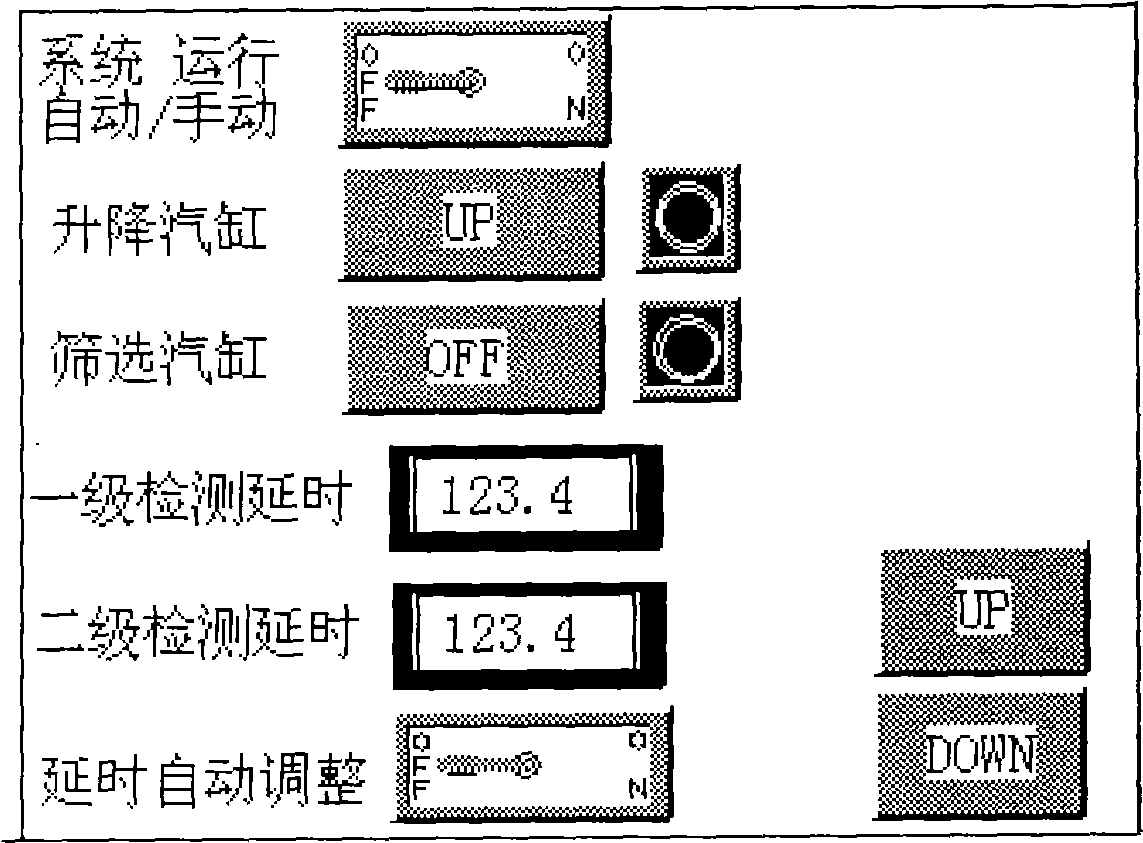

[0032] Refer to attached figure 2 , figure 2 It is the touch screen of the control system to control the second screen, which is mainly used for debugging and maintenance of the control system. The main operation of manual control is completed on the second screen.

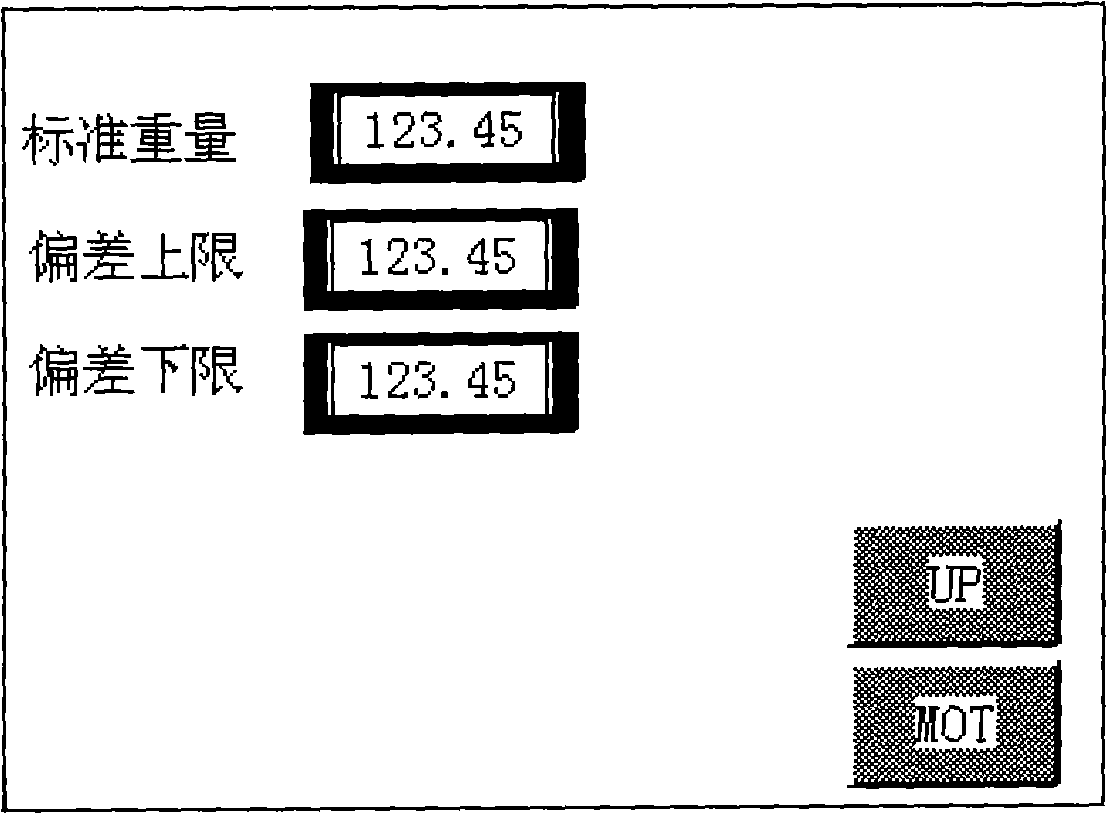

[0033] Refer to attached image 3 , image 3 It is the touch screen control screen 3 of the automatic weighing transmission quality control system for powder molding products. Screen 3 is used to set the standard weight of the product to be weighed, the upper and lower limits of weight de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com