LED device

A technology of light-emitting diodes and light-emitting chips, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of unseen technology development, no prevention, and reduced efficiency of phosphor powder, so as to increase the sorting range, be less prone to heat, and improve the mixing efficiency. light effect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

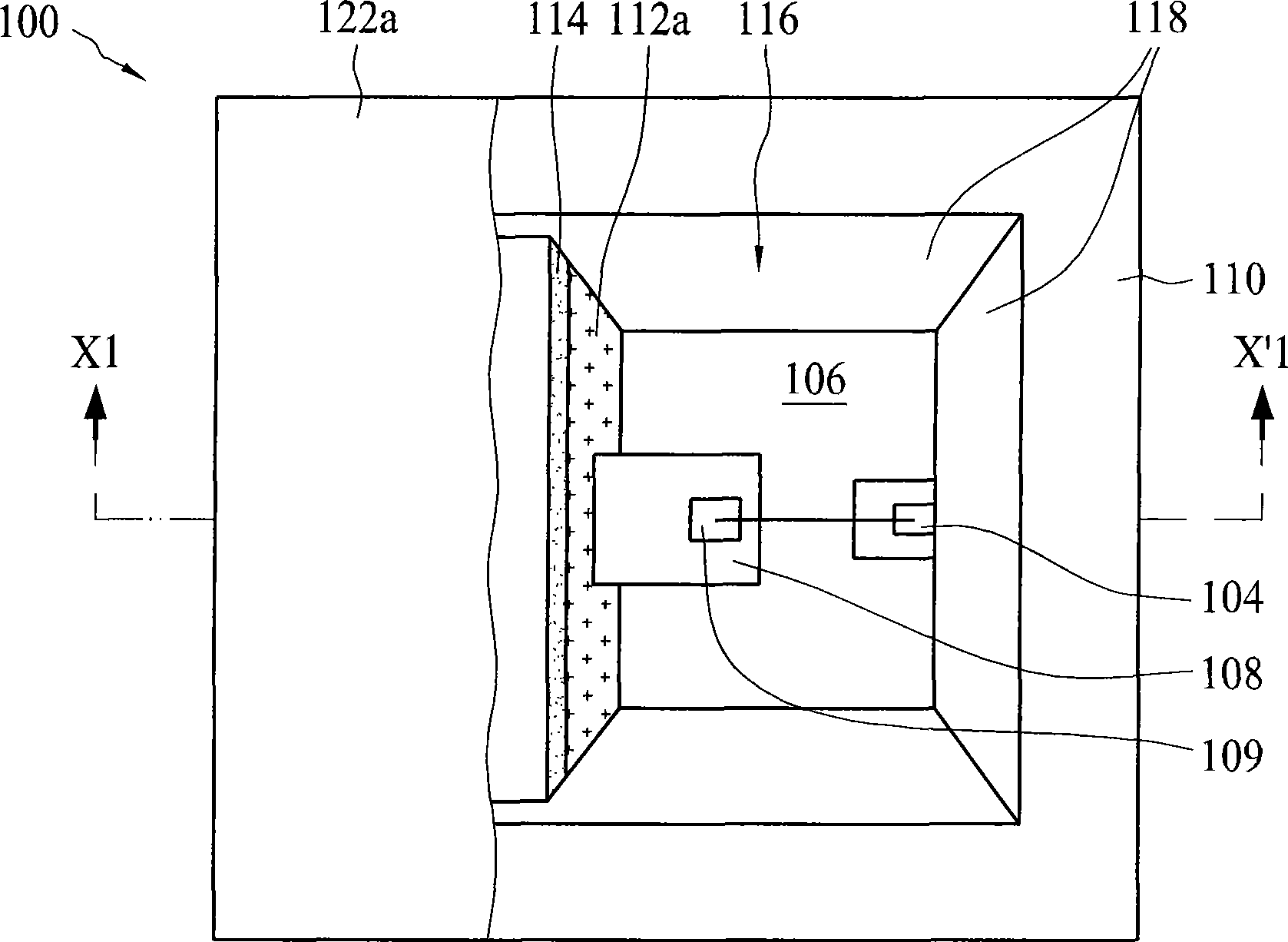

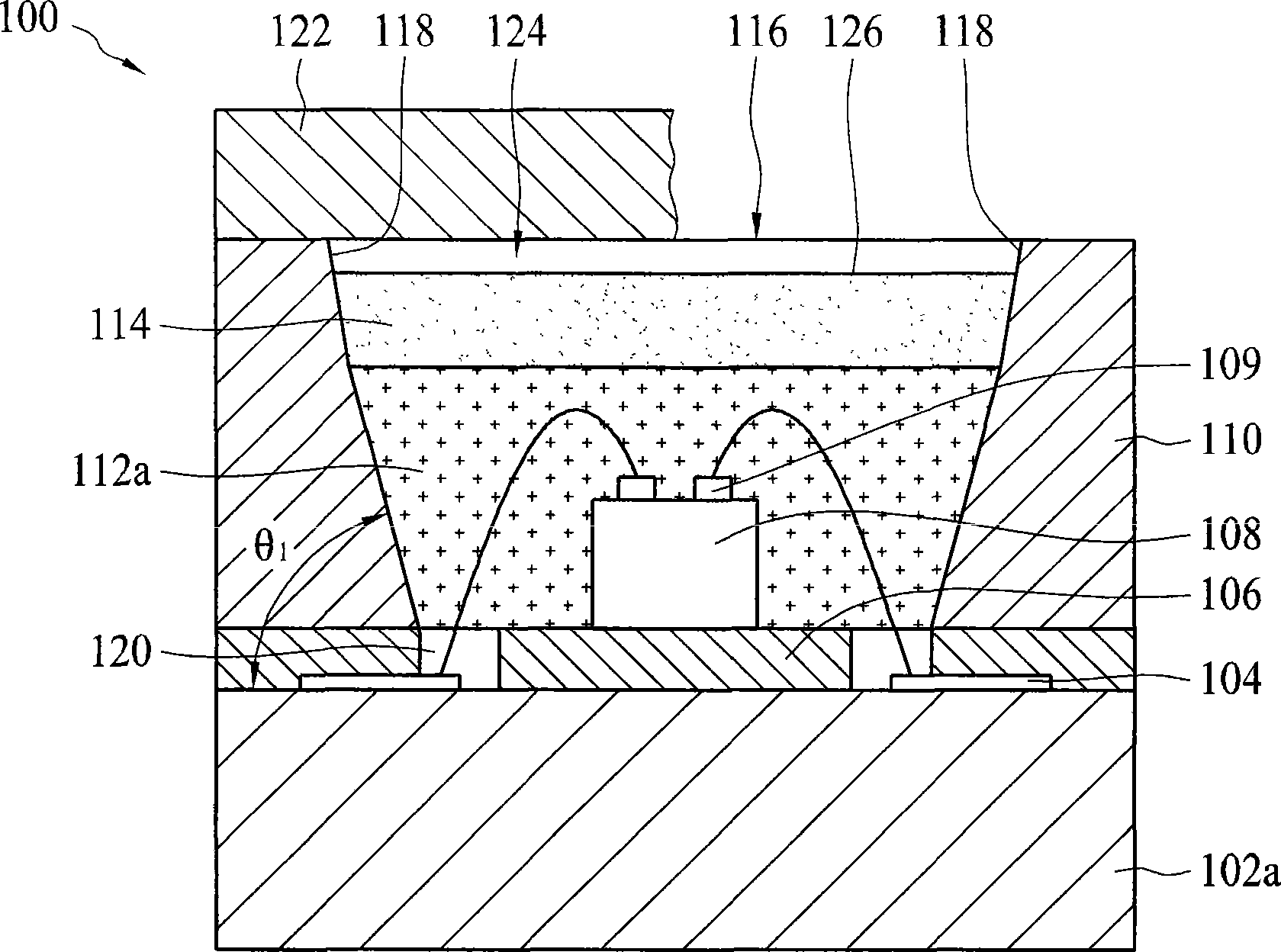

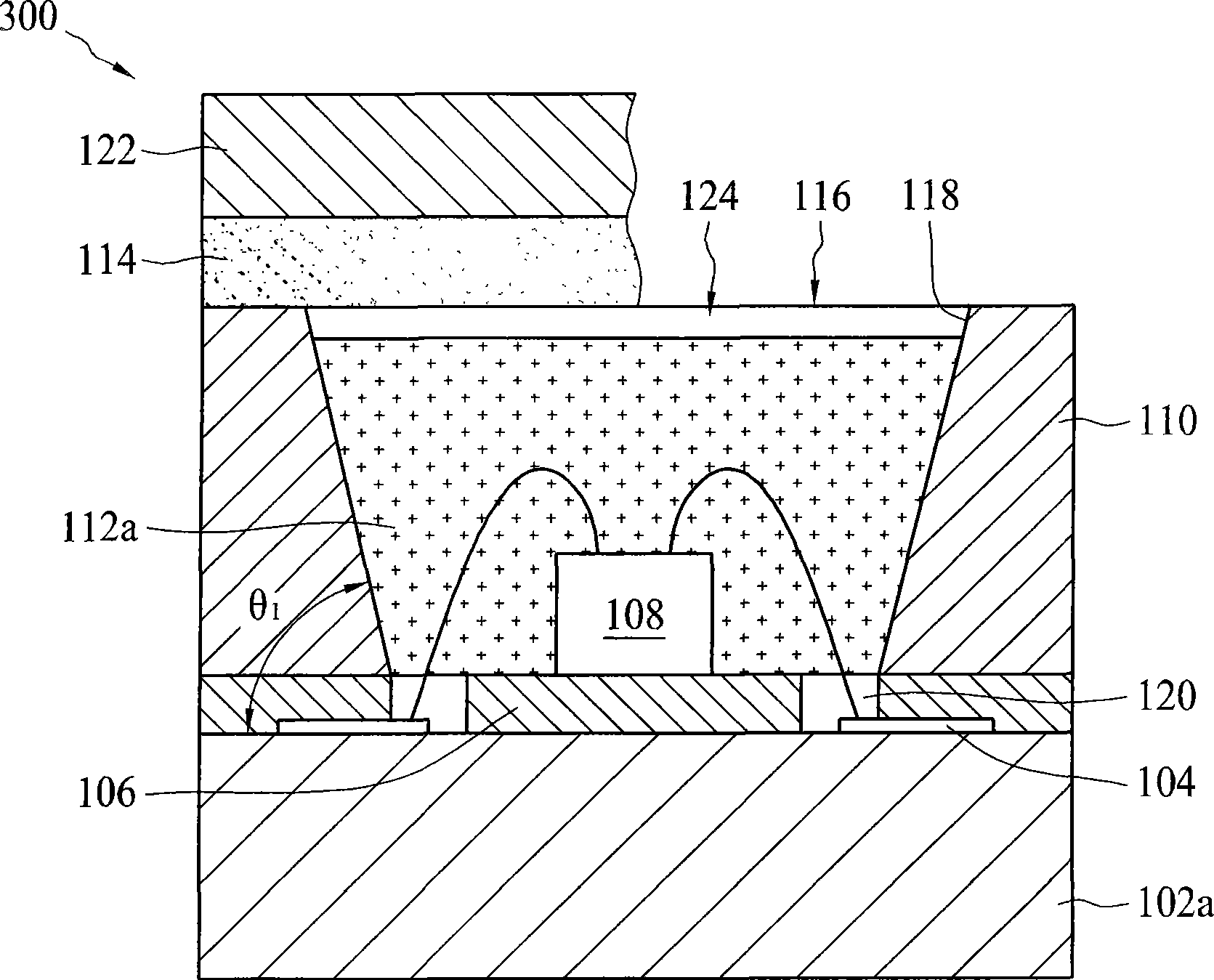

[0044] figure 1 A top view of the LED device 100 according to the first embodiment of the present invention is shown. figure 2 for figure 1 Sectional view along section line X1-X’1. The LED device 100 includes a substrate 102a with a circuit pattern 104, a reflective layer 106 disposed on the substrate 102a, at least one light-emitting chip 108 disposed on the reflective layer 106, and a reflector 110 surrounding the light-emitting chip 108. , a colloid 112a covering the light-emitting chip 108 and a phosphor layer 114 disposed on the colloid 112a for uniform light mixing. The light-emitting chip 108 has a conductive portion 109 , and the circuit pattern 104 of the substrate 102 a is connected to the conductive portion so as to provide driving power for the light-emitting chip 108 .

[0045] The reflector 110 includes a light emitting surface 116 at the outlet of the reflector and a first reflective surface 118 at the inner edge of the reflector. The first reflective surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com