Output current compensation circuit of LED driving circuit

A technology of LED drive and output current, which is applied in the direction of lamp circuit layout, electric light source, and adjustment of electric variables, etc. It can solve the problems of affecting the life of LED load, poor steady current characteristics of LED drive circuit, and difficult control of LED load current, etc., and achieves improvement. Effect of constant current characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The content of the present invention will be further described below in conjunction with the accompanying drawings.

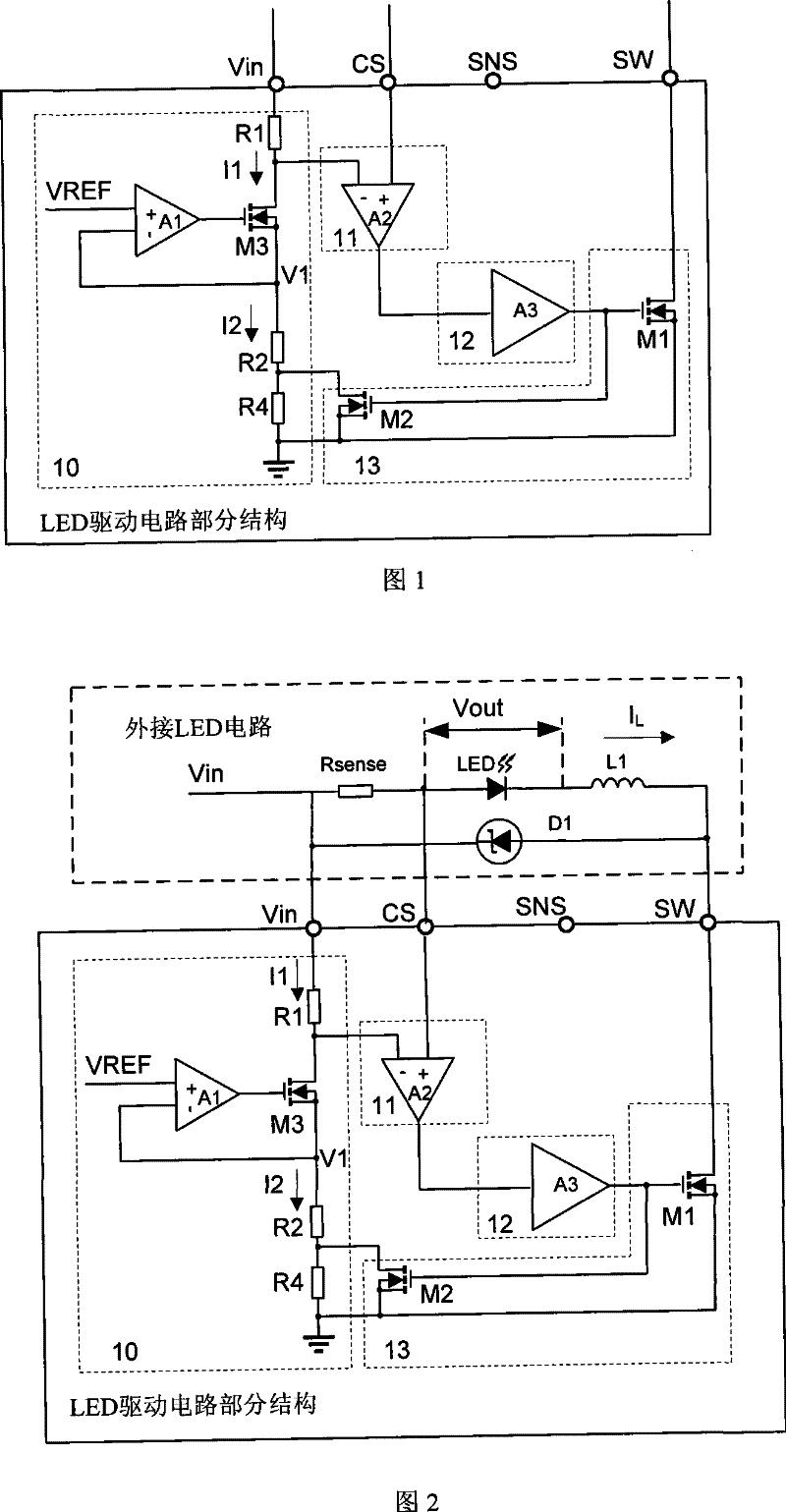

[0056] as attached figure 1 When the LED driving circuit (partial circuit structure) shown is driving the LED load, the LED driving circuit is connected with an external LED circuit to form an LED driving circuit system. The system structure is as follows figure 2 As shown: the external LED circuit includes a serial connection of sampling resistor Rsense, LED load, inductor and Schottky diode D1; the sampling resistor Rsense is connected across the Vin port and CS port of the LED drive circuit; the LED The positive pole of the load is connected to the CS port of the LED driving circuit, the negative pole is connected to one end of the inductor, and the other end of the inductor is connected to the SW port of the LED driving circuit; the Schottky diode D1 is connected across the Vin port of the LED driving circuit With the SW port, its PN junction is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com