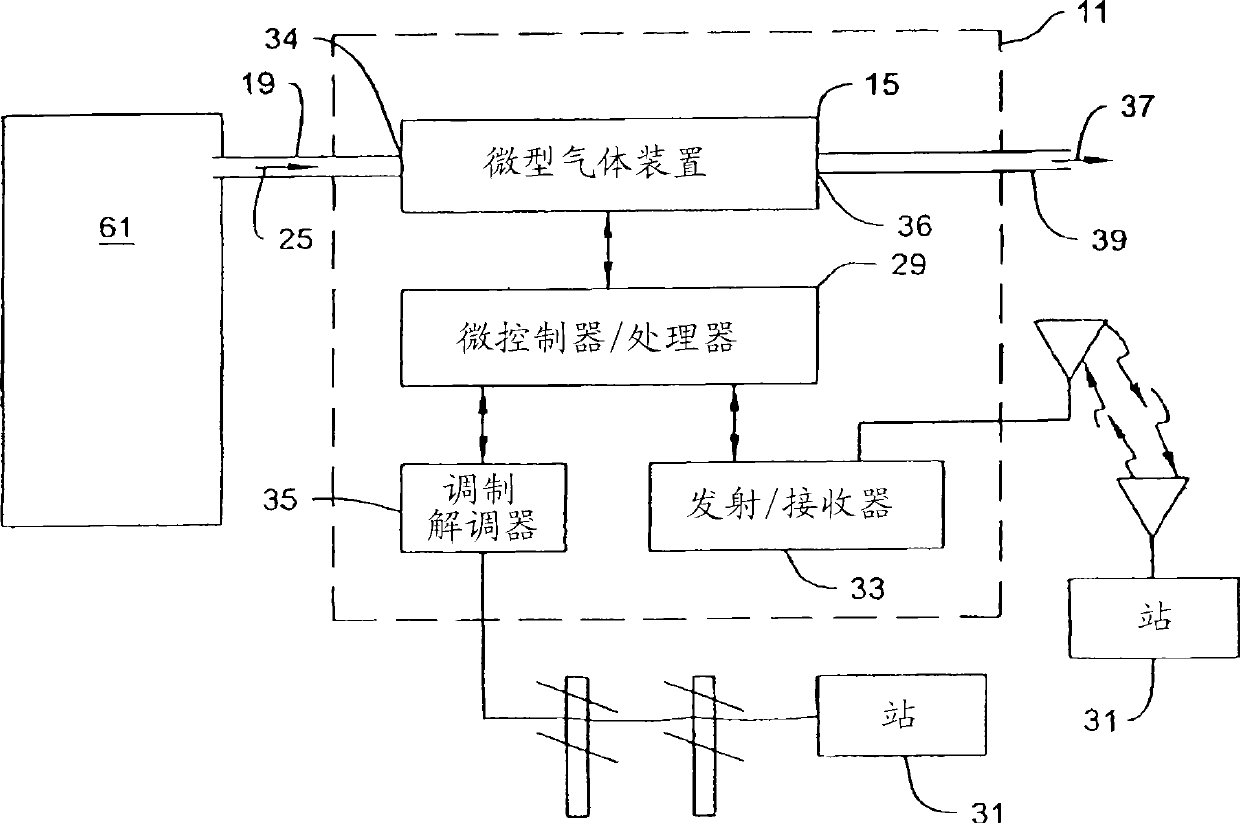

Phased VII micro fluid analyzer having a modular structure

A fluid analysis, modular technology, applied in the analysis of materials, analysis of gas mixtures, instruments, etc., can solve the problems of lack of flexibility in pre-concentration and separation capabilities, increased volume and labor costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

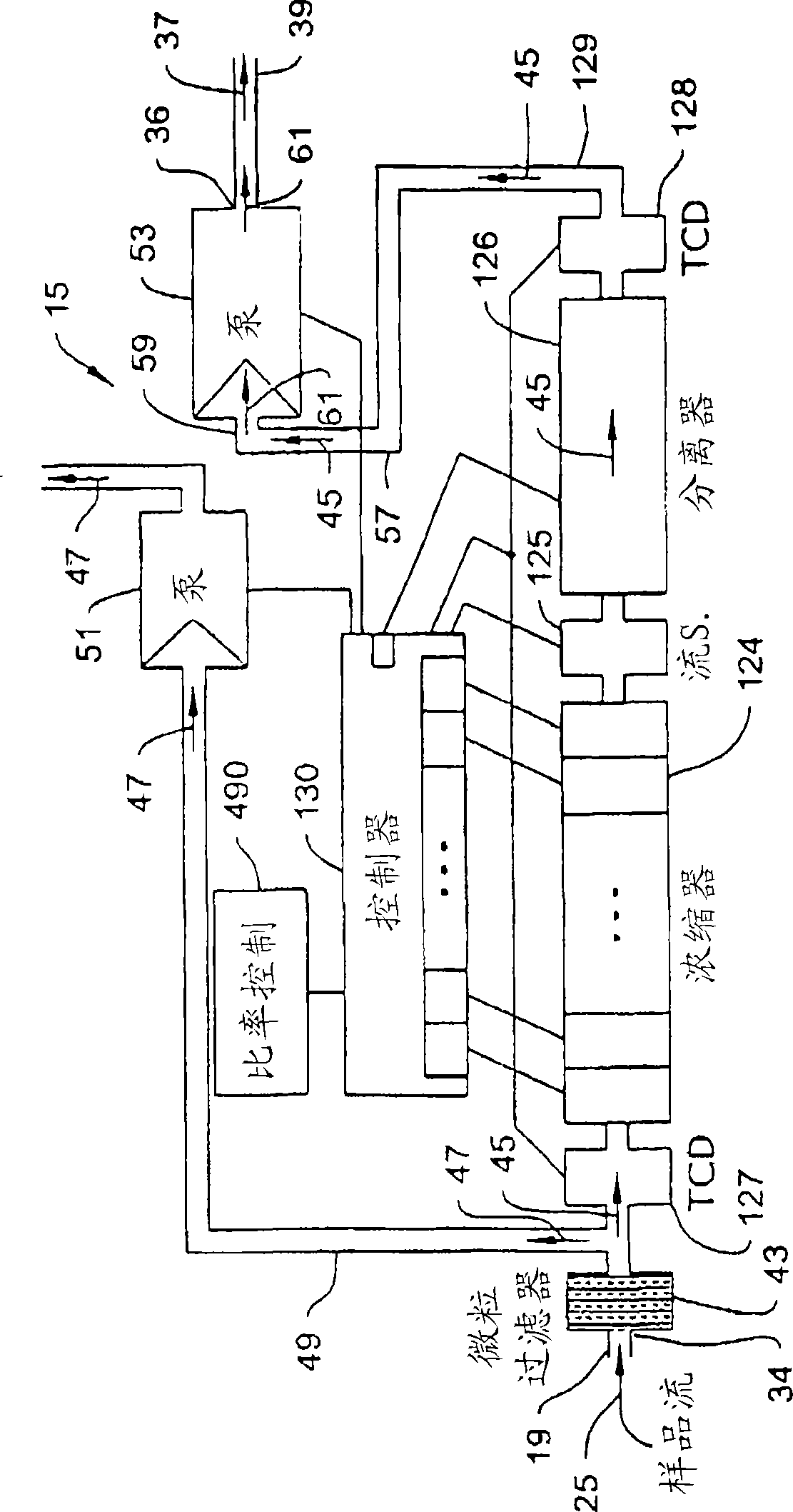

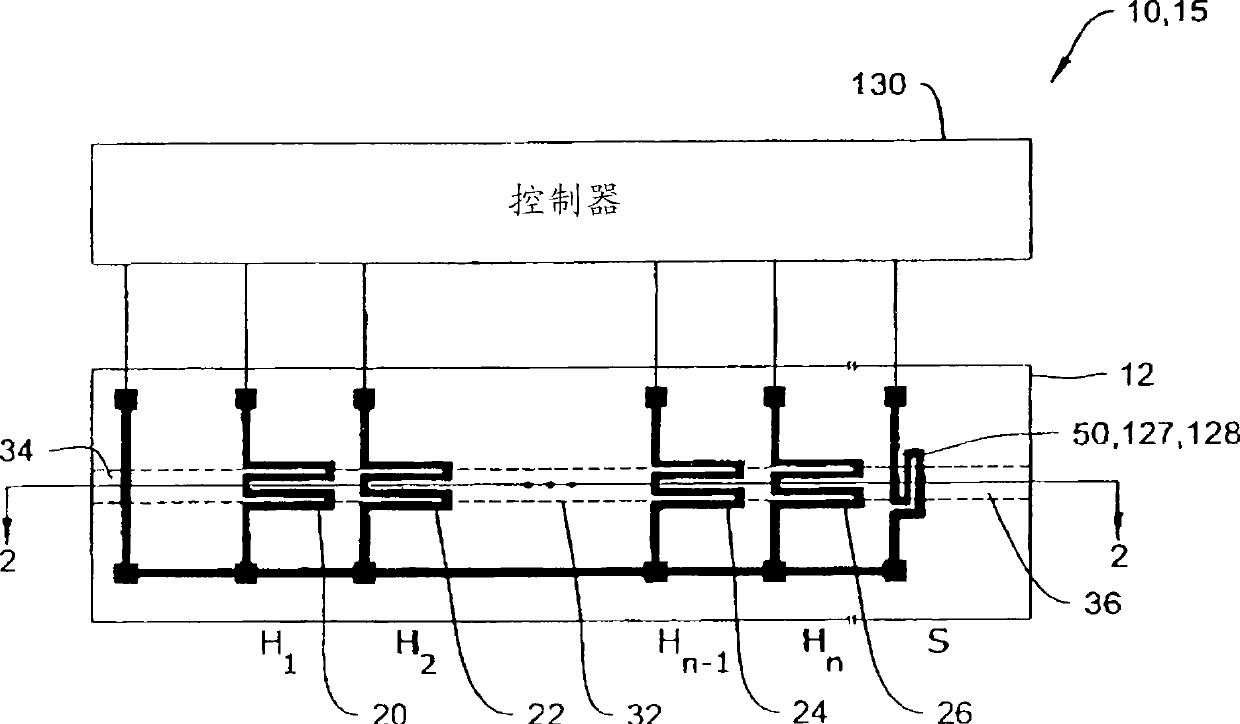

[0051]On the one hand, other fluid sensor systems that include phased heater sensors may not take advantage of multiple new detector concept, which would even require a manufacturing process that is incompatible with older model phased heater sensor systems. On the other hand, connecting (ie "daisy-chaining") separate phased heater elements such as preconcentrators and separators with available microassemblies runs the risk of widening the GC half-peak width and reducing resolution. In this specification, the term "fluid" may be a general term specifically including gas and liquid.

[0052] The equipment which can also increase the manufacturing capacity can have modular standard building blocks for the micro-analyzer element of the phase-controlled heater sensor, thereby reducing the overall manufacturing time and design complexity, allowing the development of independent components at the same time, This results in accelerated development and still offers integration benefi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com