Weld signature monitoring method and apparatus

A technology of welding equipment and feature classification, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problem that the comparison has not yet reached the best

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

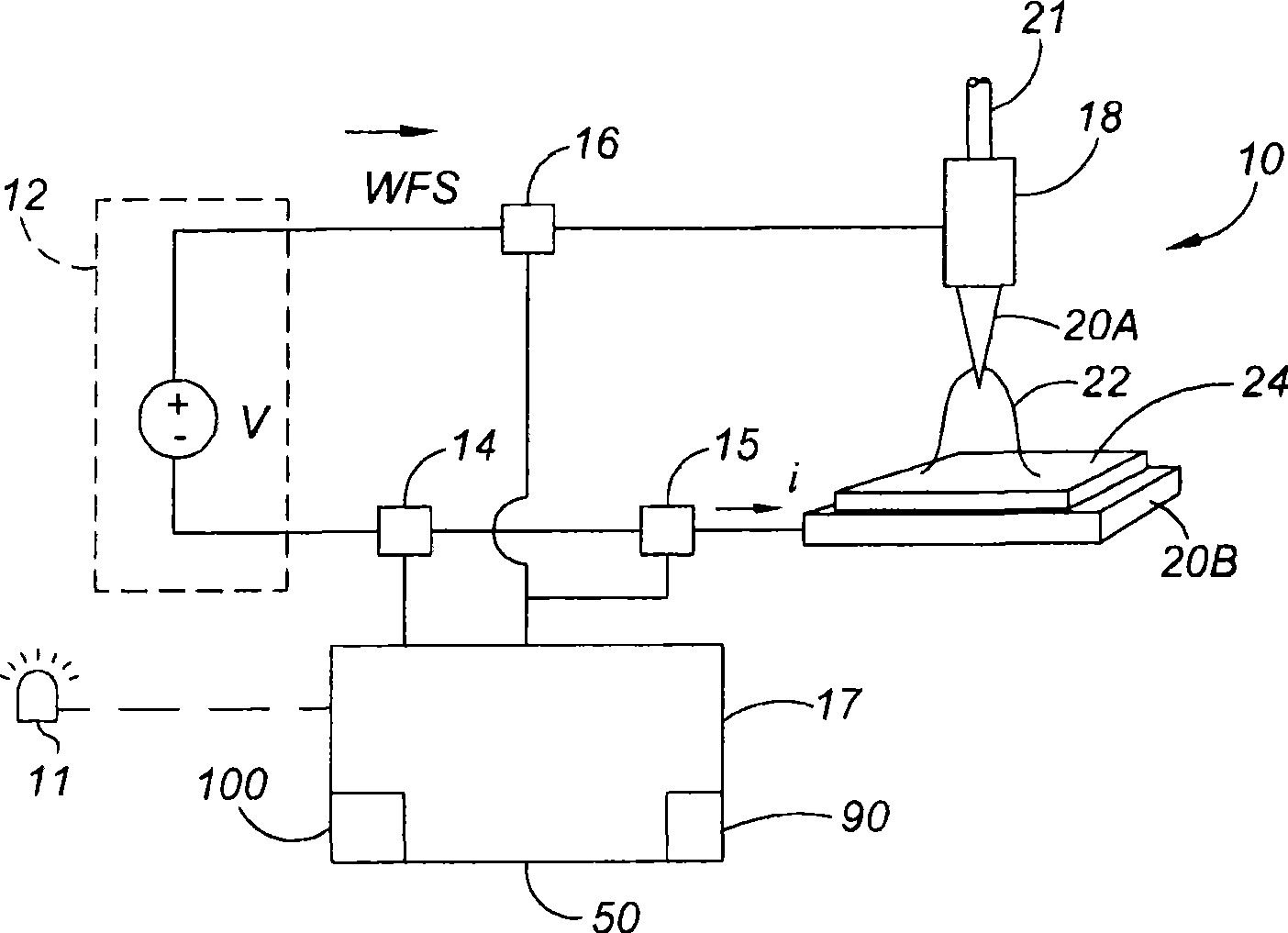

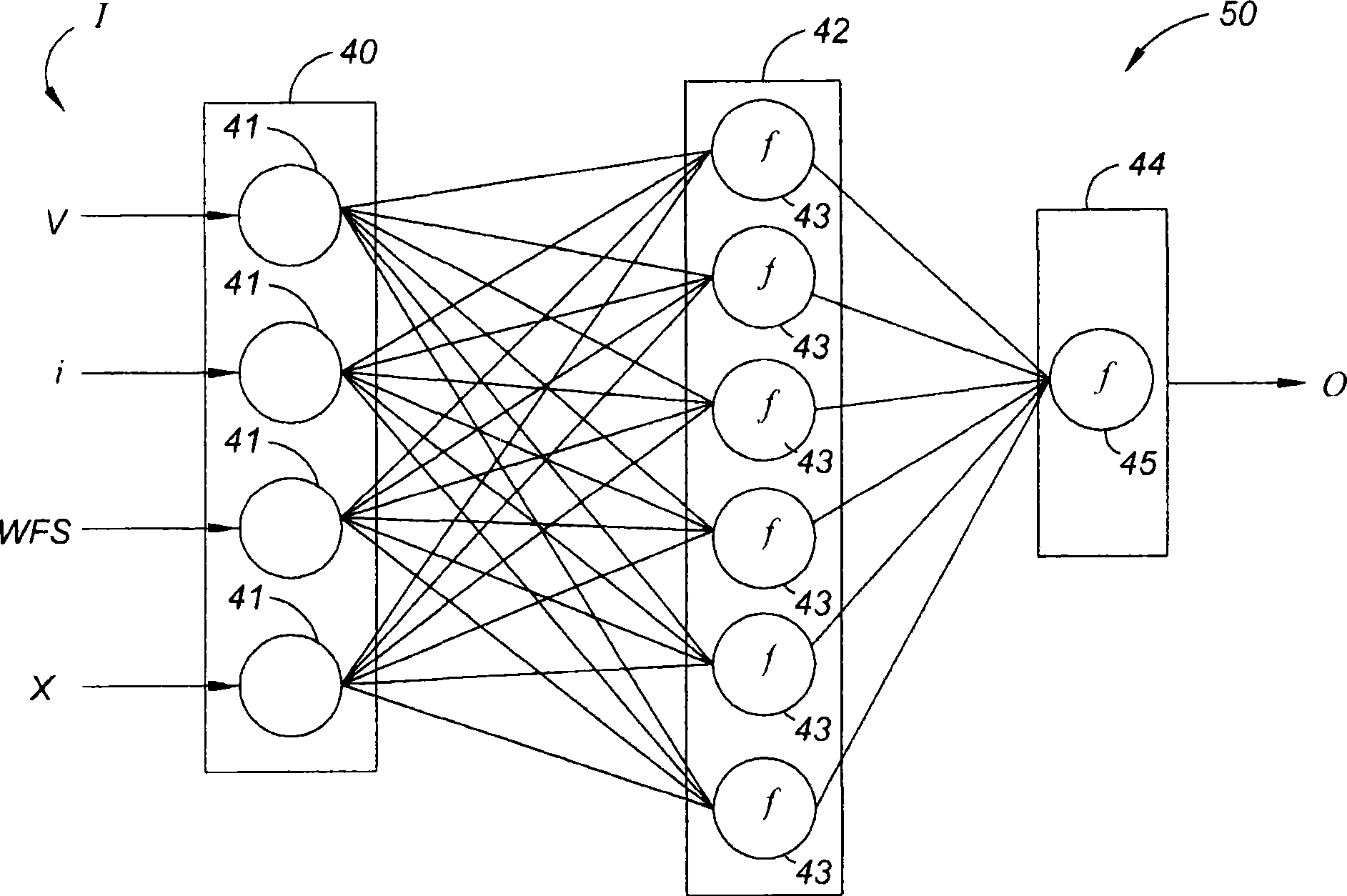

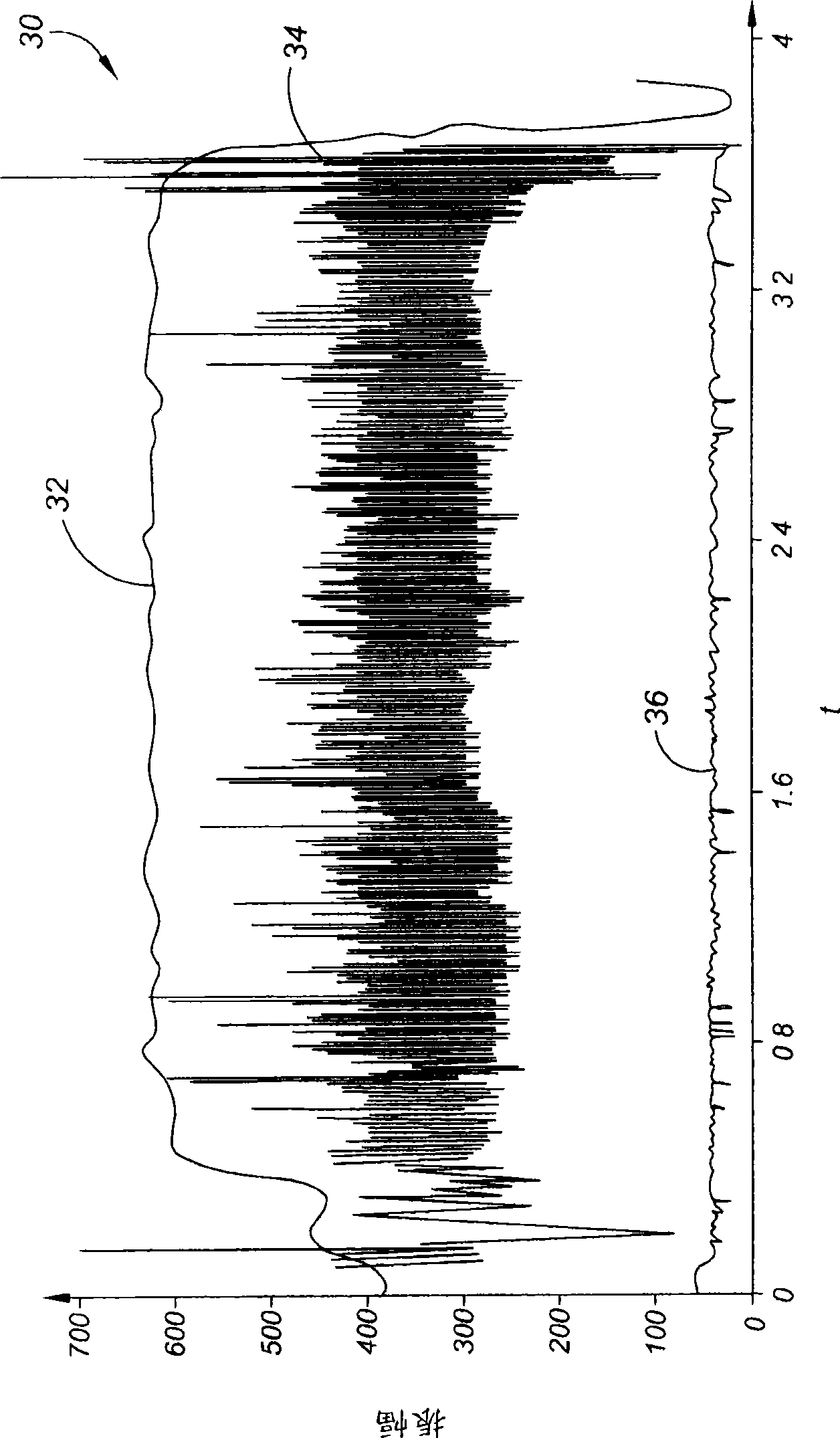

[0020] Referring to the drawings, wherein like reference numerals correspond to like or similar components throughout the several figures, and from figure 1 Initially, an apparatus and method are provided for monitoring the welding characteristics of a welding process, which can be used in a variety of welding processes, including but not limited to single workpiece operations, combining two or more workpieces Either surfaces are joined together and / or are used to join two ends of a single workpiece together. Accordingly, the welding apparatus 10 includes an automated or manual welding device or welding torch 18 operatively connected to an integrated control unit or controller 17 and a power supply 12 that provides a voltage at figure 1 is represented as variable "V". Multiple sensors 14, 15, and 16, which may alternatively be configured as a single sensor and / or housed together in a common sensor housing (not shown), are suitable for sensing, measuring, detecting, and / or oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com