Special rope groove for changing mining multiple rope pulley hoist steel wire rope

A technology of steel wire rope and hoisting rope, which is applied in the field of replacing large-diameter steel wire ropes, can solve the problems that new steel wire ropes cannot be occupied and have no place to be placed, and achieves the effect of improving construction safety and being fast, easy to dismantle, and easy to process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

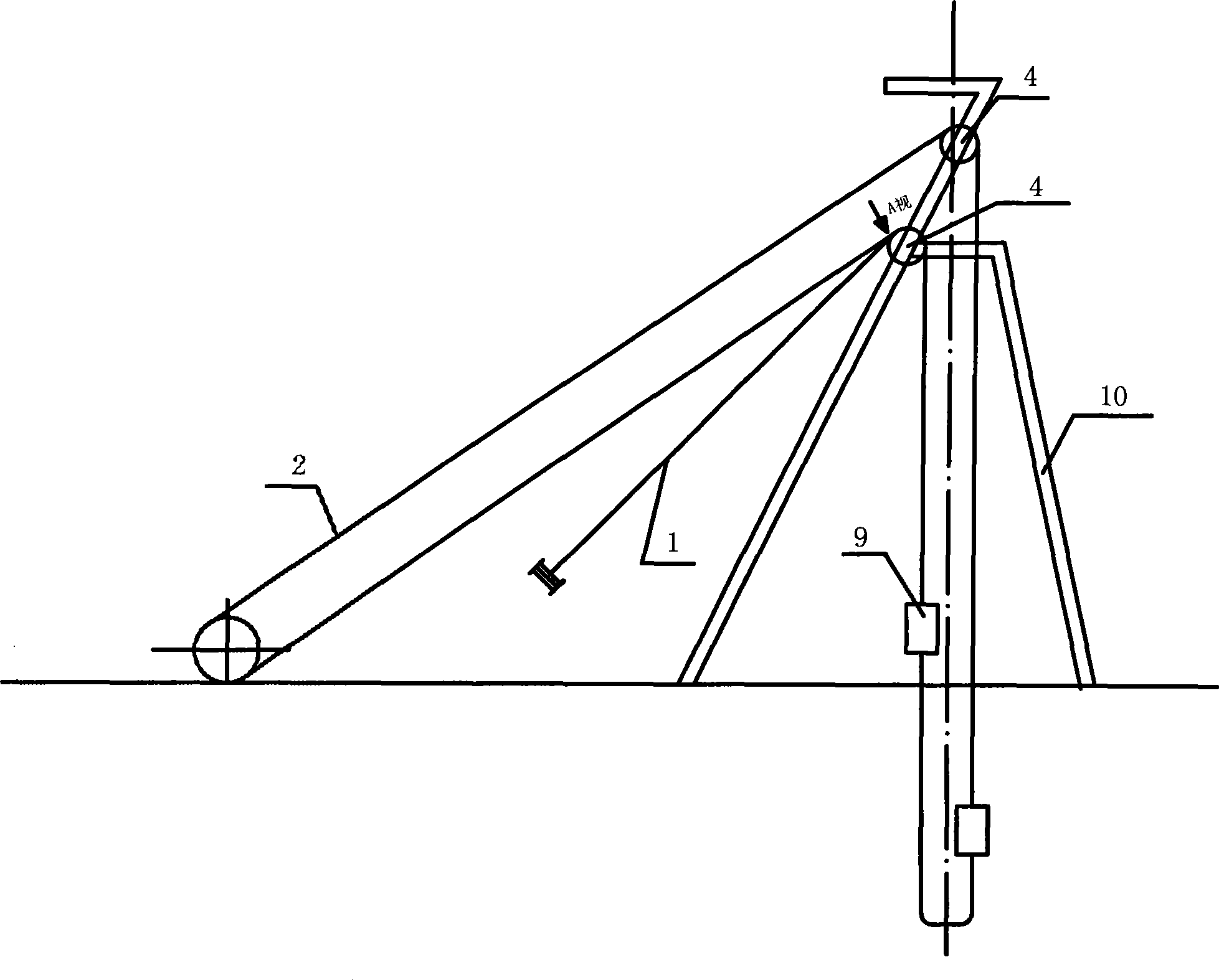

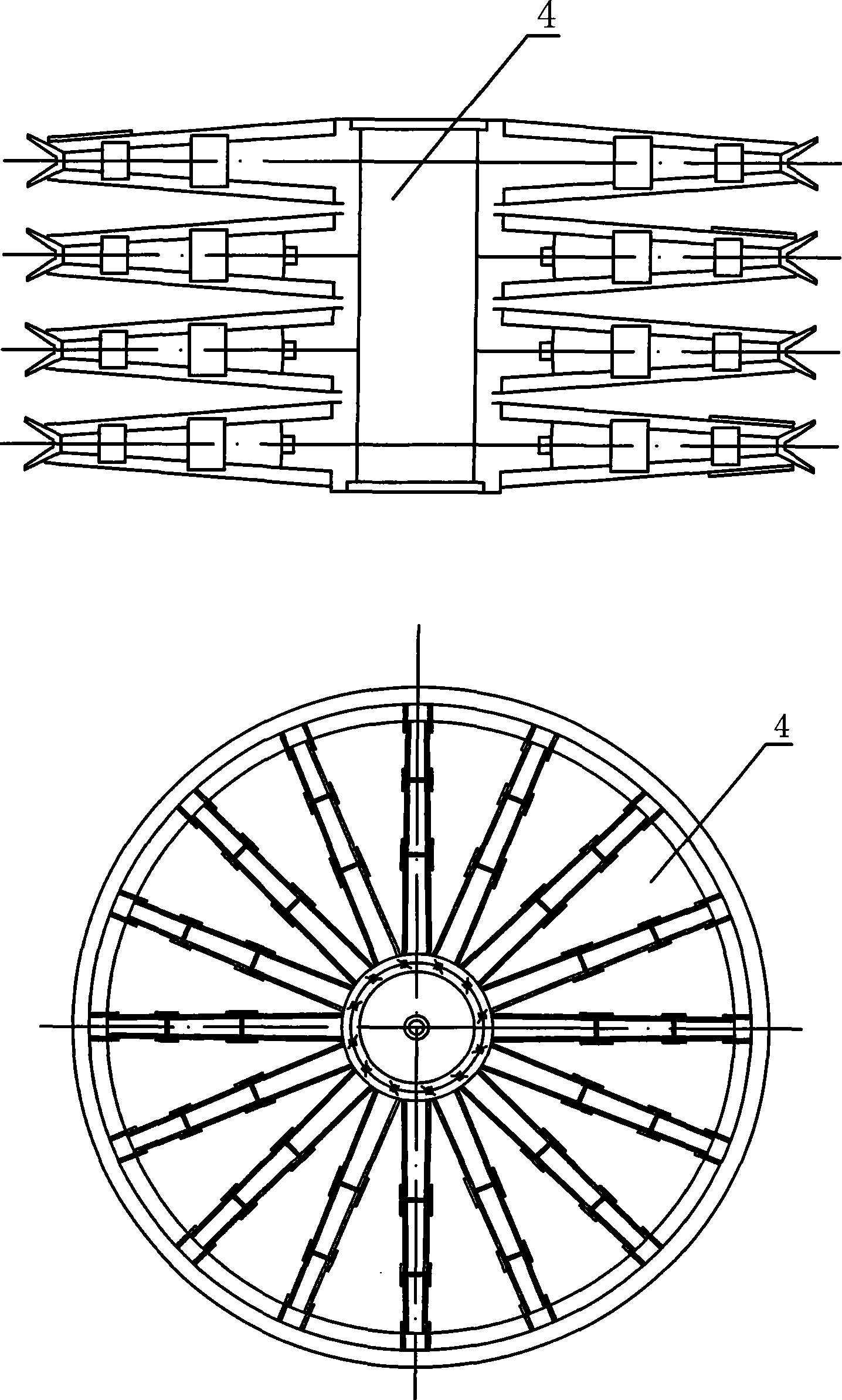

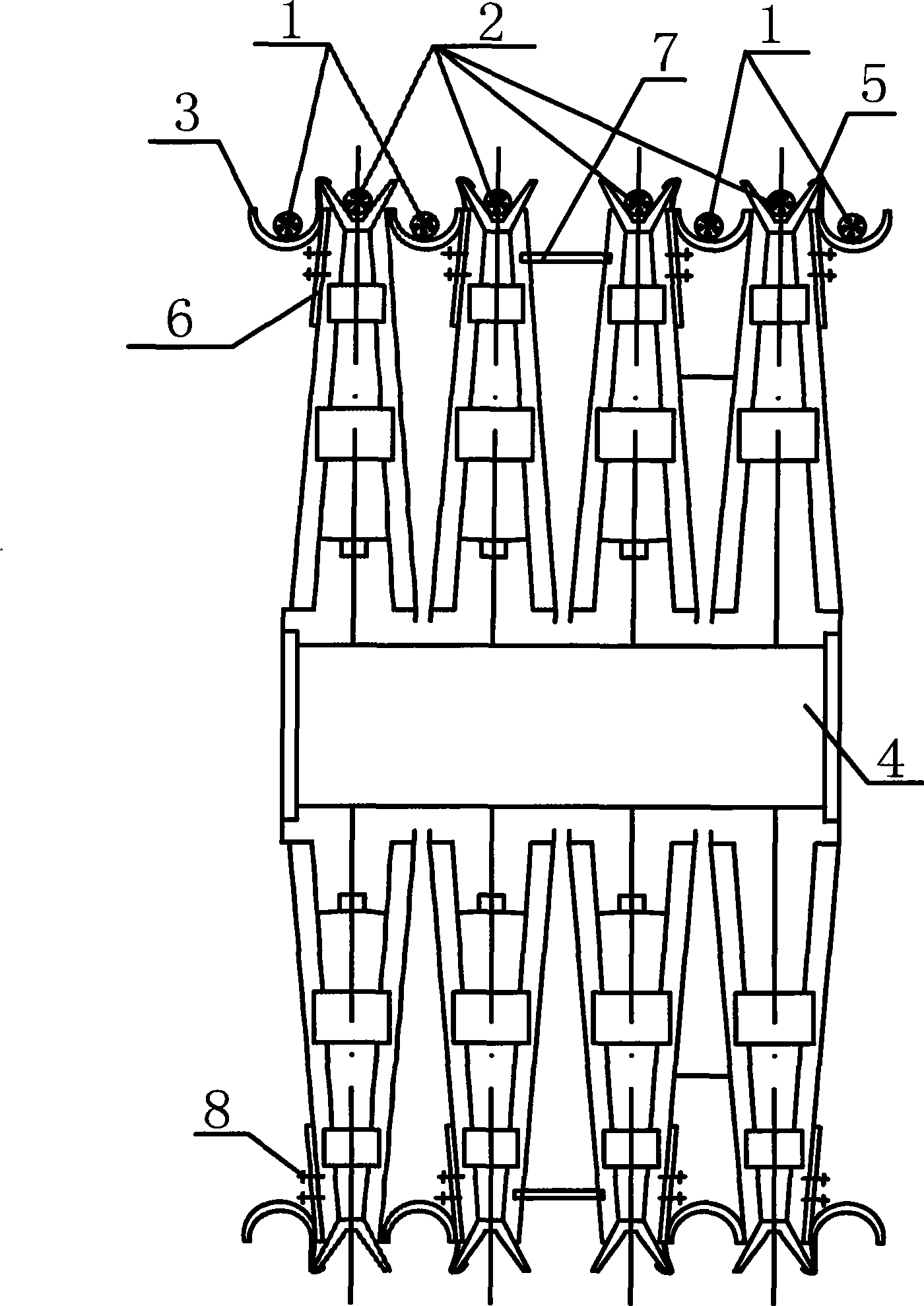

[0018] 1. First, according to the diameter of the permanent sky wheel, simmer the steel pipe into an arc of the same diameter, and take half of the arc as the main body of the temporary rope groove. The arc length of each section is determined according to the spoke distances of different sky wheel diameters.

[0019] 2. Weld a 6 mm thick steel plate at the lower part of the temporary rope groove, and drill holes according to the spoke spacing. The main function of the steel plate is to support the main body of the rope groove and serve as a fixed connection with the permanent sky wheel spokes.

[0020] 3. At the beginning of the rope change, first fix the temporary rope groove on the permanent sky wheel with U-shaped bolts. (Taking the four sky wheels as an example, a total of four circles with the same diameter as the sky wheel are adorned.)

[0021] 4. After the whole rope changing work is completed, remove the temporary rope groove and deliver it for formal lifting operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com