Main pipe type micro turbine group of dual-air compressor

A technology of compressors and gas turbines, which is applied in the direction of gas turbine devices, combustion air/combustion-air treatment, machines/engines, etc. It can solve the high-level problems of micro gas turbine units, and achieve the effects of improving operating performance, saving fuel, and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

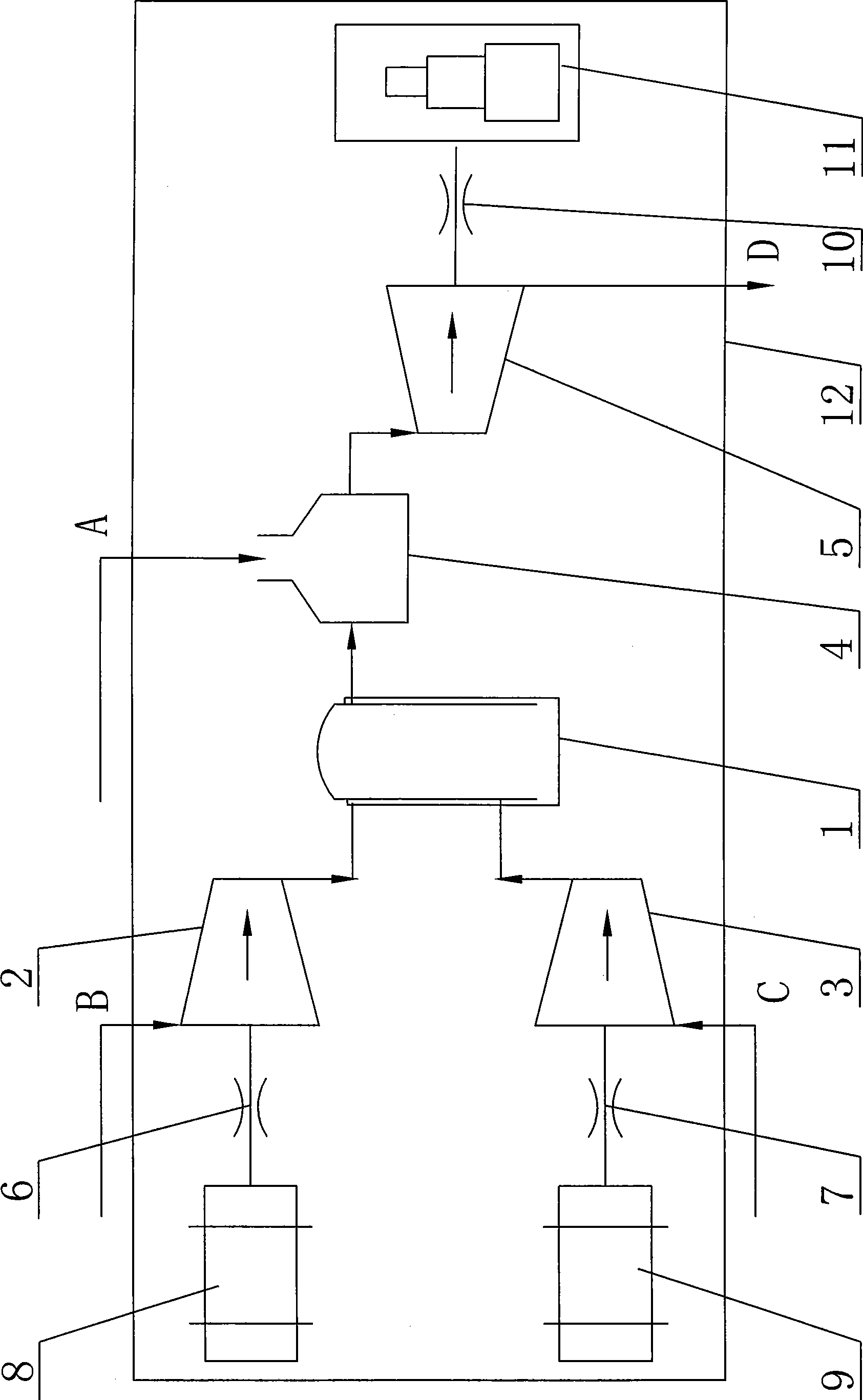

[0008] Specific implementation mode one: as figure 1 As shown, the dual-compressor main pipe type micro gas turbine unit described in this embodiment includes a main engine room 12, a combustion chamber 4, a turbine 5 and a third laminated coupling 10, and the micro gas turbine unit also includes a first electric motor 8. The second motor 9, the first lamination coupling 6, the second lamination coupling 7, the first compressor 2, the second compressor 3 and the main pipe 1; the combustion chamber 4, the turbine 5 , the third disc coupling 10, the first motor 8, the second motor 9, the first disc coupling 6, the second disc coupling 7, the first compressor 2 and the second compressor 3 and The main pipes 1 are all arranged in the main engine compartment 12; the output shaft of the first motor 8 is connected with the input shaft of the first compressor 2 through the first lamination coupling 6, and the output shaft of the second motor 9 is connected through the second laminati...

specific Embodiment approach 2

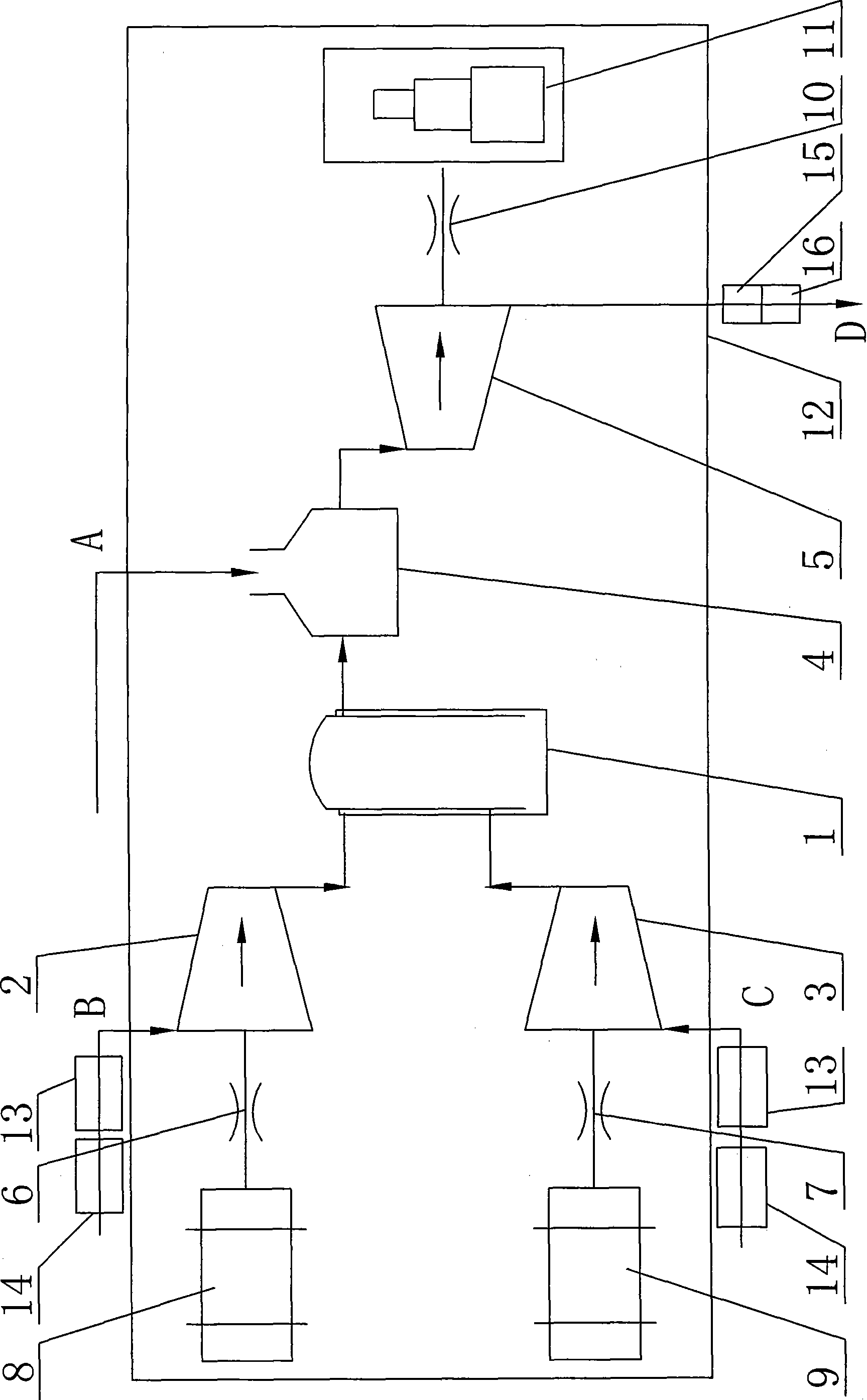

[0010] Specific implementation mode two: as figure 2 As shown, the micro gas turbine unit in this embodiment also includes two filter noise reduction devices 13 and two cabin ventilation intake noise reduction devices 14. End C is respectively provided with a filter noise reduction device 13 and a cabin ventilation intake noise reduction device 14 , and the two filter noise reduction devices 13 and two cabin ventilation intake noise reduction devices 14 are both arranged outside the main cabin 12 . Filtration noise reduction device 13 and cabin ventilation intake noise reduction device 14 are all prior art. Setting the filtering and muffler device 13 can effectively reduce and shield the noise generated by the present invention during operation, so that the noise around the unit can be effectively controlled and noise pollution can be reduced. The cabin ventilation intake muffler 14 is set so that the cabin temperature is slightly higher than the ambient temperature when the...

specific Embodiment approach 3

[0011] Specific implementation mode three: as figure 2 As shown, the micro gas turbine set in this embodiment also includes an exhaust introduction section 15 and an exhaust muffler device 16, and the exhaust introduction section 15 and the exhaust muffler device 16 are sequentially arranged at the exhaust outlet of the turbine 5. D, and the exhaust introduction section 15 and the exhaust muffler 16 are both arranged outside the main cabin 12 . Both the exhaust introduction section 15 and the exhaust muffler 16 are prior art. Exhaust introduction section-exhaust muffler device 15 can make smoke exhaust smoothly, and can further eliminate noise. Other compositions and connections are the same as those in Embodiment 1 or 2.

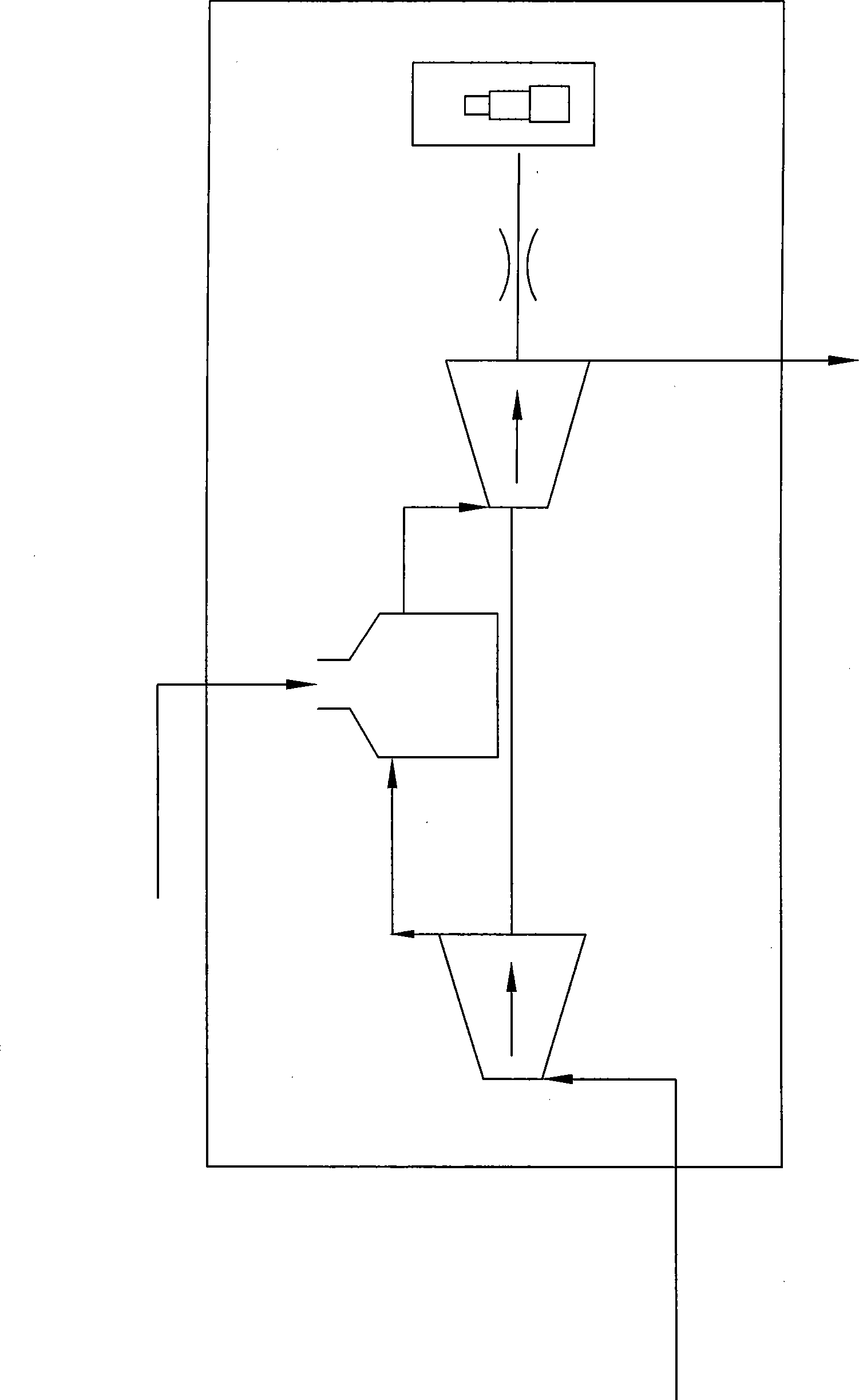

[0012] working principle

[0013] The working process of the present invention is: two independent electric motors drive the compressor, the high-pressure air generated by compression enters the main pipe for mixing, the mixed air enters the combustion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com