Printing process control system

A technology of process control and process selection, which is applied in the direction of instruments, electrical components, and cooperative operation devices, can solve problems such as batch scrapping, difficulty, and inability to form a system, so as to improve risk prevention capabilities, prevent errors, and improve product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

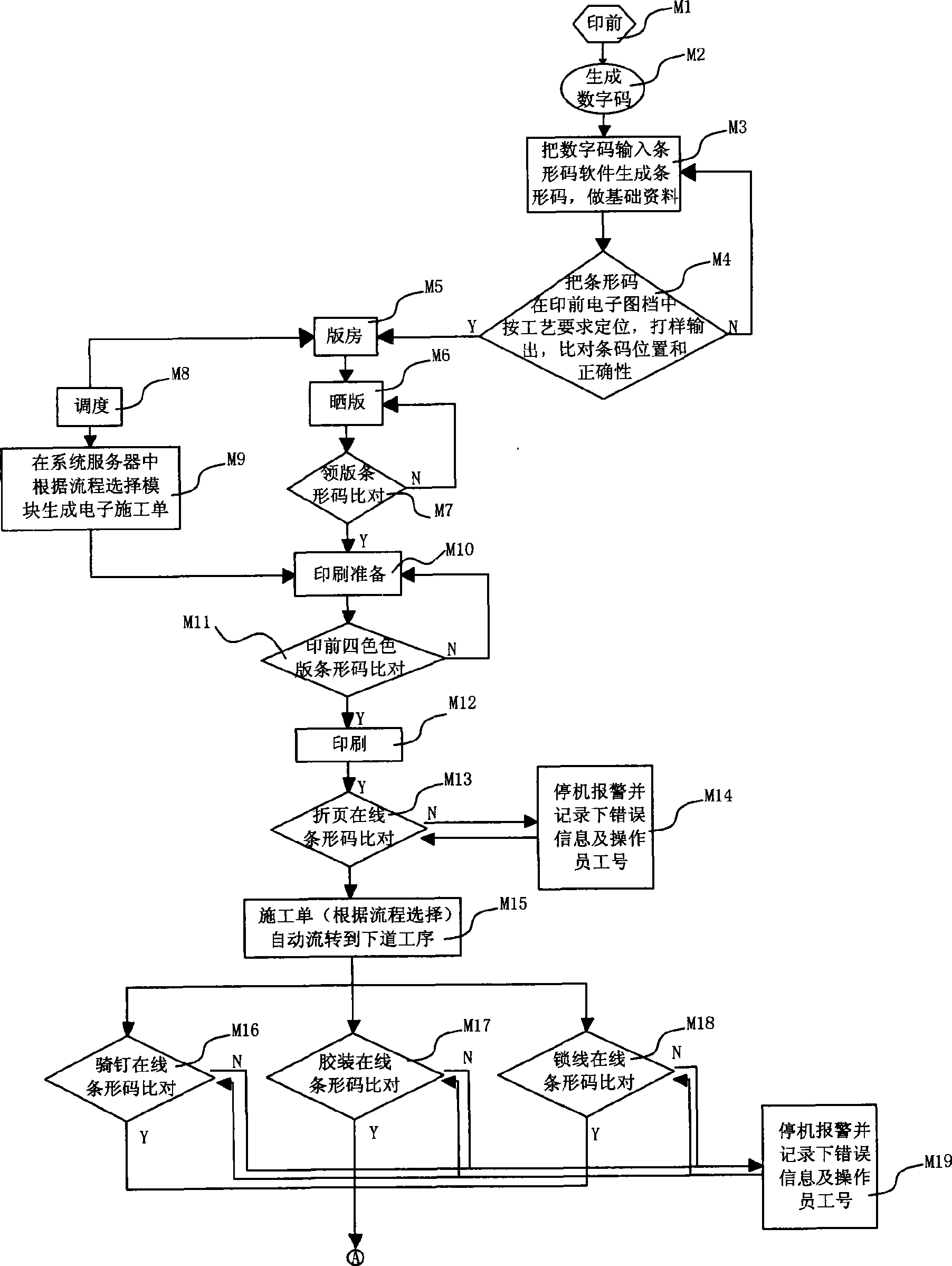

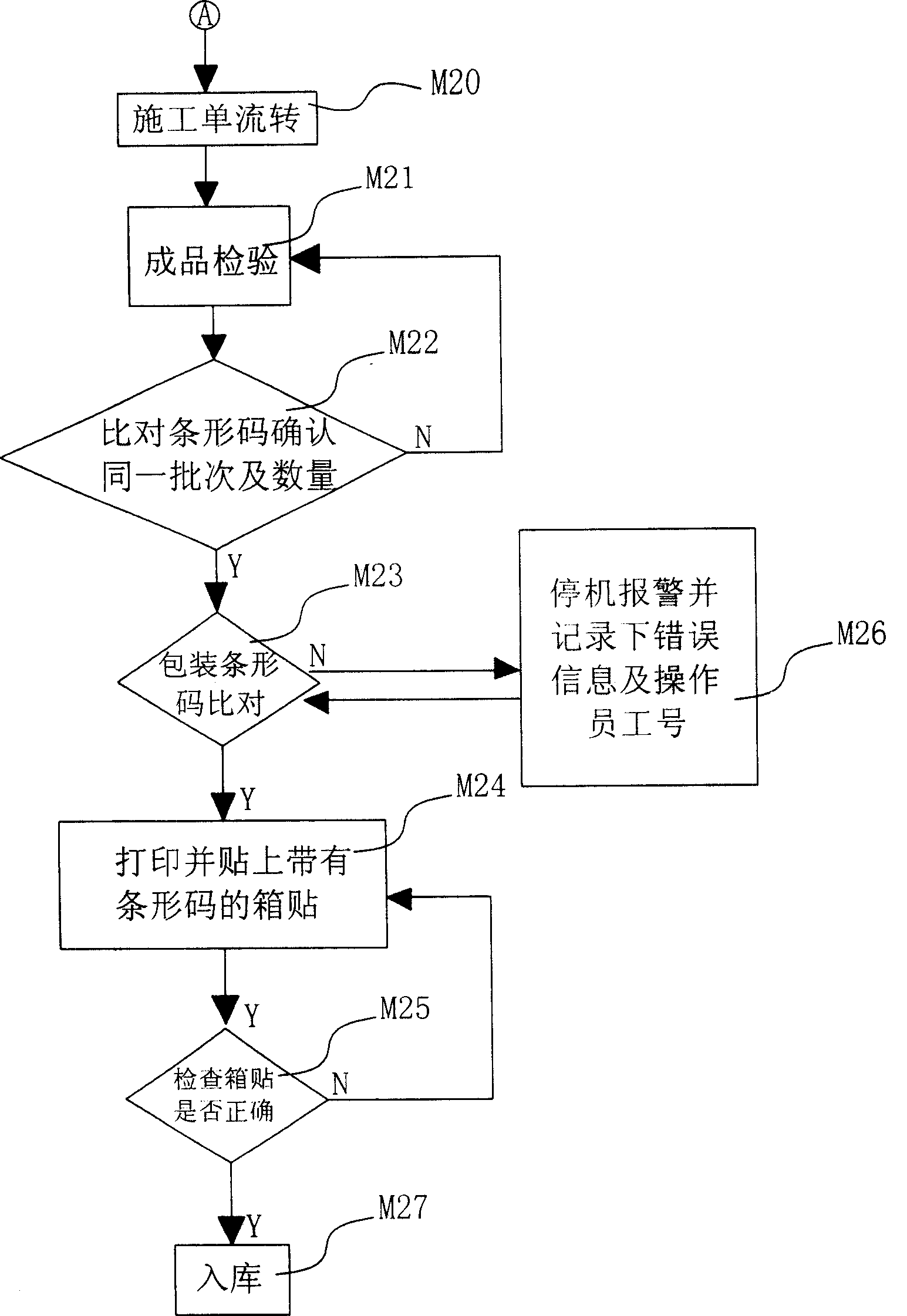

[0048] The present invention will be further described below in conjunction with the accompanying drawings.

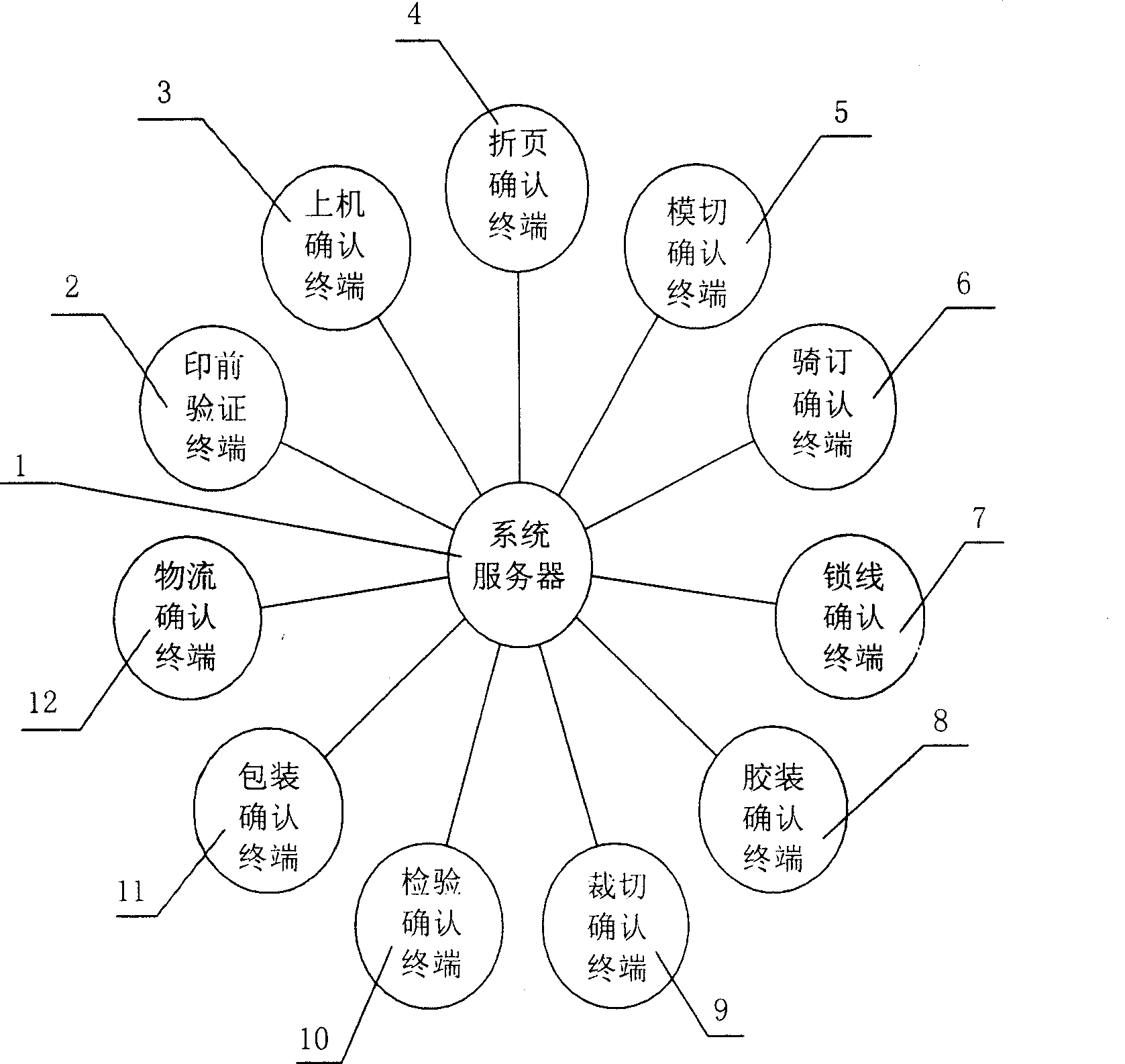

[0049] The printing process system includes pre-press verification terminal 2, on-machine confirmation terminal 3, folding confirmation terminal 4, die-cutting confirmation terminal 5, saddle-stitching confirmation terminal 6, thread-locking confirmation terminal 7, perfect binding confirmation terminal 8, cutting confirmation Terminal 9 , inspection confirmation terminal 10 , packaging confirmation terminal 11 or logistics confirmation terminal 12 , each terminal is equipped with a scanner, and each terminal is communicatively connected with system server 1 .

[0050] FIG. 2 is the main flow of the method for the system server 1 to perform error prevention and error correction control on the printing process. Step M1 receives the order number of the product before printing, and then step M2 arranges the received product order number and the number of stickers in order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com