Swirling flow producing apparatus, method of producing swirling flow, vapor phase generating apparatus, microbubble generating apparatus, fluid mixer and fluid injection nozzle

A technology for generating devices and fluids, which is applied in the direction of fluid mixers, mixers, injection devices, etc., can solve the problems of the outflow direction being limited to one direction, increase the amount of fluid processing, and low adaptability, and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

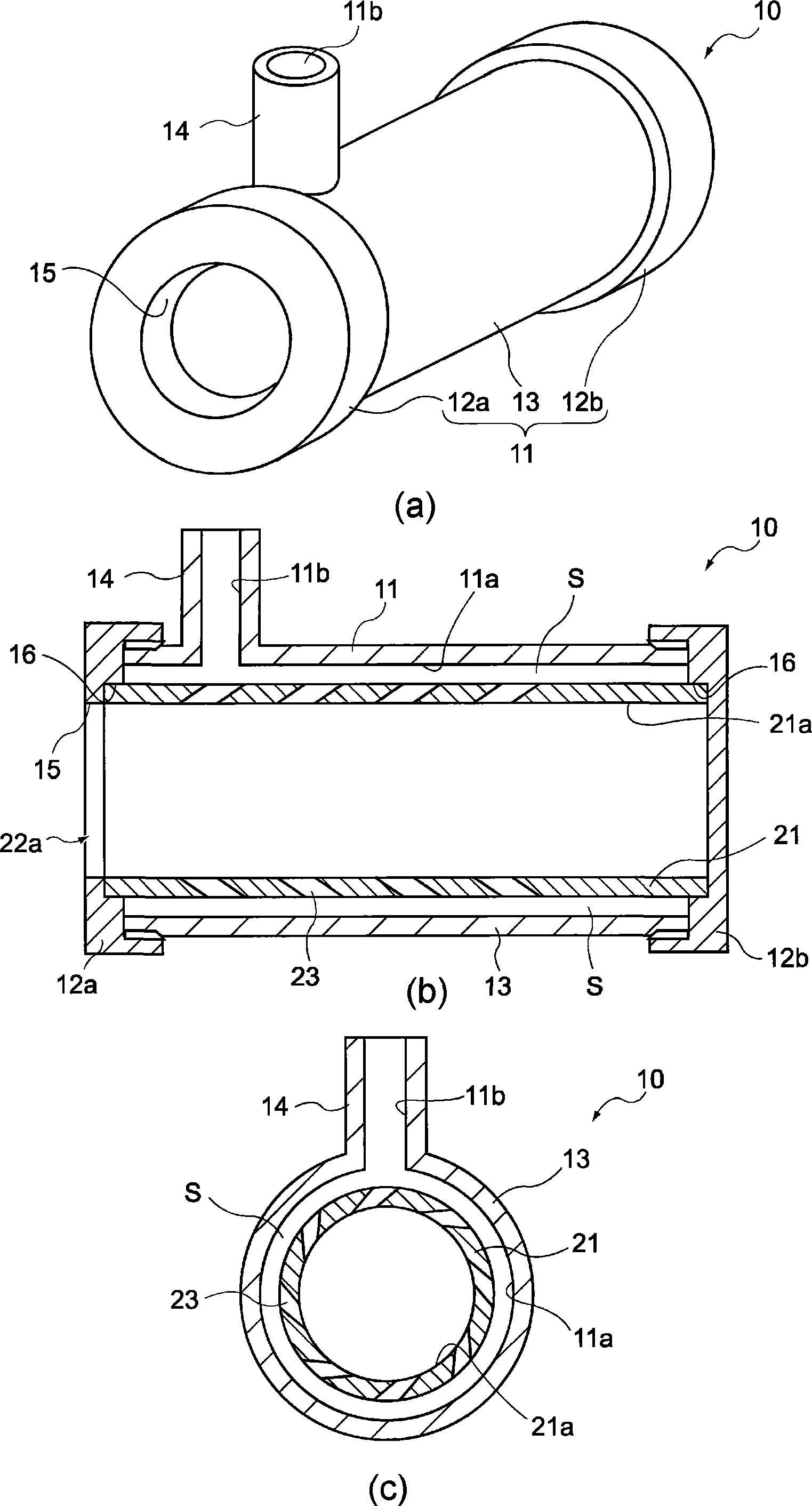

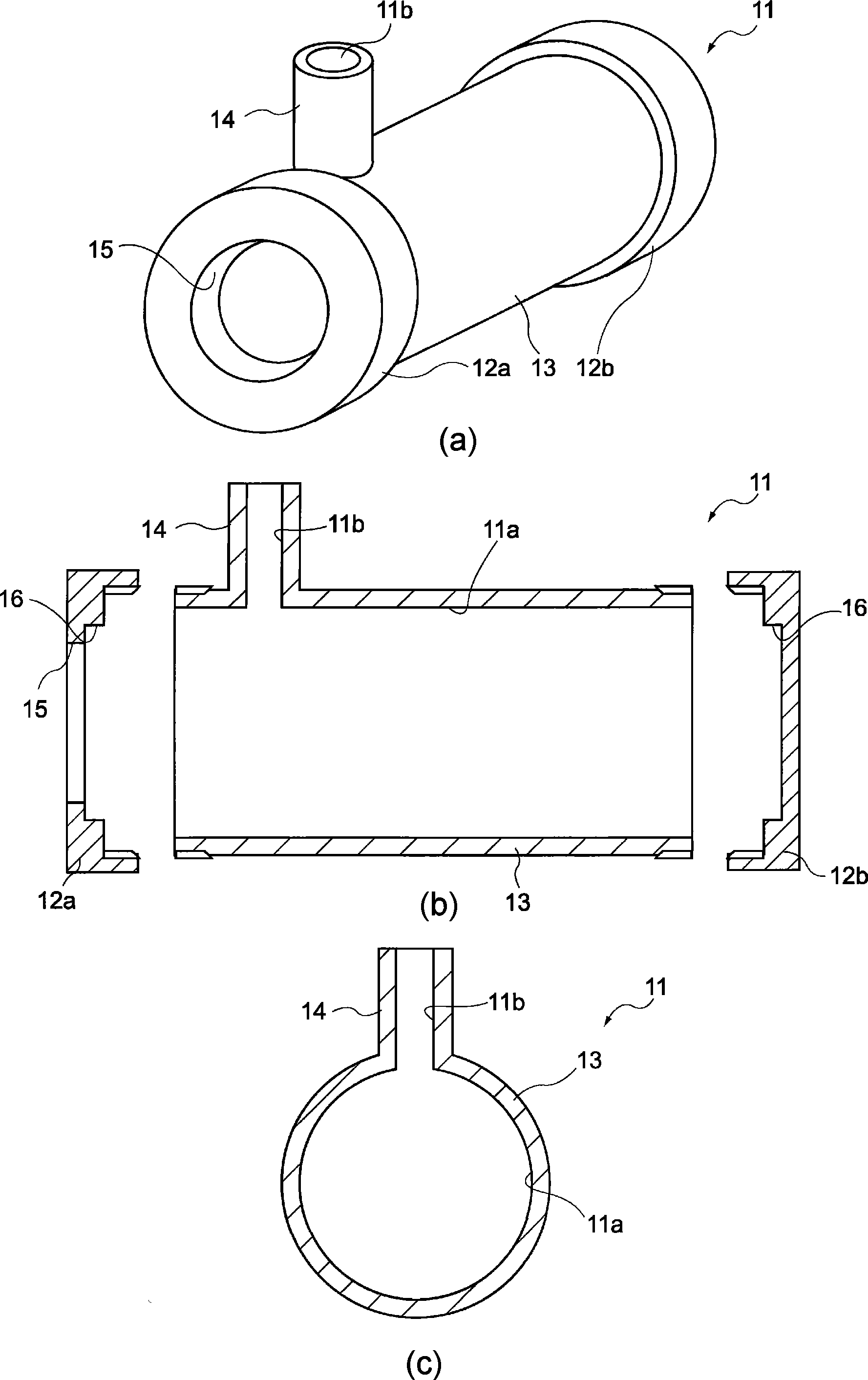

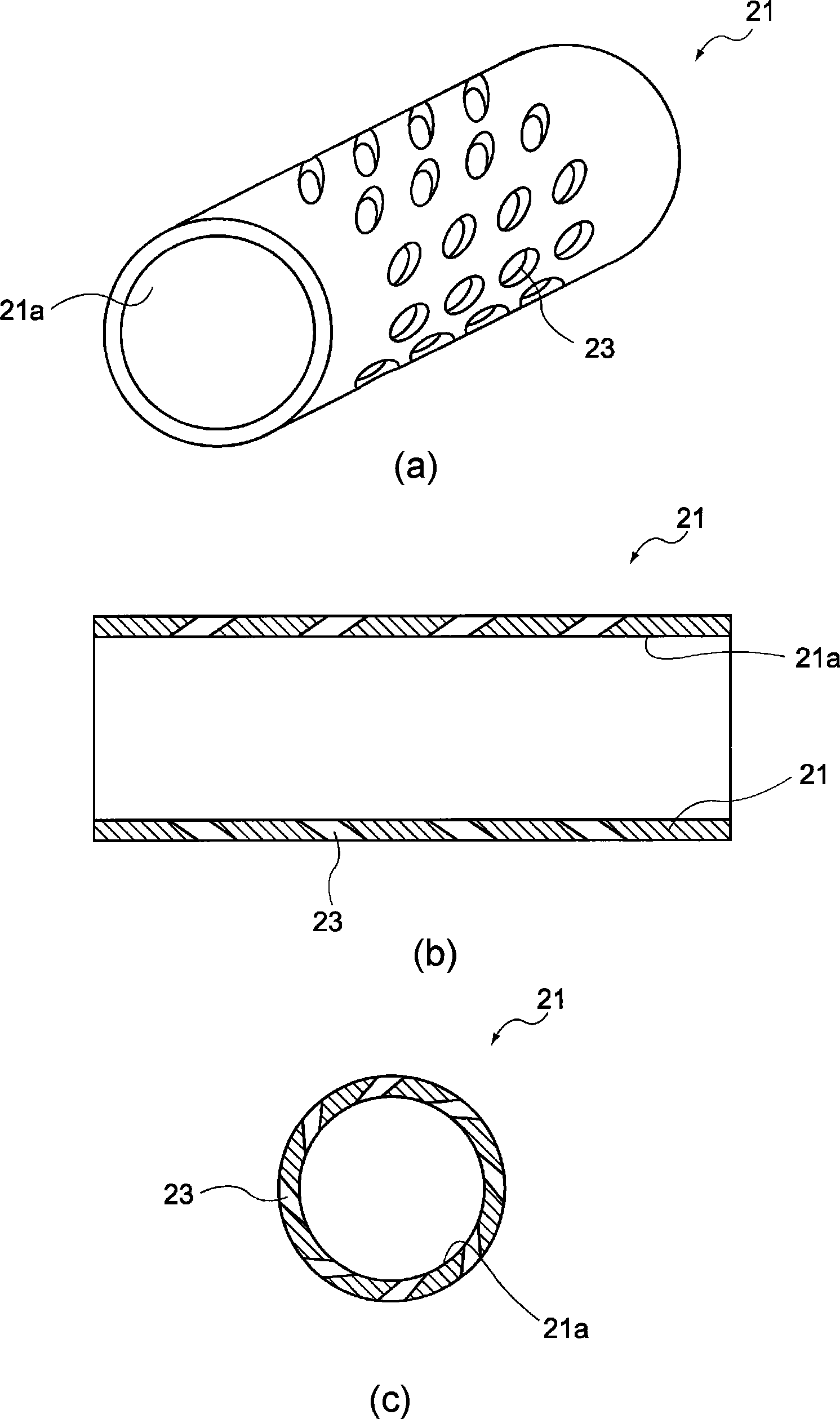

[0081] A first embodiment of the present invention is a swirl flow generation device and a swirl flow generation method using the swirl flow generation device, that is, the swirl flow generation device includes a housing and a cylindrical member, and the housing includes at least A cylindrical space part with one end open and a fluid introduction path open on the inner peripheral surface of the cylindrical space part, the cylindrical member is disposed in the cylindrical space part of the casing, and has at least a connection with the cylindrical space part. A cylindrical space portion opened at the end in the same direction as the opening direction and a hole portion opened on the peripheral wall of the cylindrical space portion, wherein the liquid fluid introduced from the fluid introduction path flows into the circle of the cylindrical member through the hole portion. In the space of the cylinder, swirling flow is generated, and it flows out from the casing and the cylindric...

no. 2 approach

[0144]A second embodiment of the present invention provides a gas phase generating device using the swirl flow generating device described in the first embodiment, and includes a housing and a cylindrical member. The housing includes at least one A cylindrical space part with an opening at the end of the cylindrical space part and a fluid introduction path opened at the inner peripheral surface of the cylindrical space part, the cylindrical member is arranged in the cylindrical space part of the casing, and has at least the opening of the cylindrical space part The cylindrical space portion opened at the end portion in the same direction and the hole portion opened on the peripheral wall of the cylindrical space portion allow the liquid fluid introduced from the fluid introduction path to flow into the cylindrical space of the cylindrical member through the hole portion. While generating a swirl in the inner part, let it flow out from the casing and the cylindrical member, ther...

no. 3 approach

[0149] A third embodiment of the present invention provides a micro-bubble generating device that uses the swirl flow generating device described in the first embodiment, and includes a housing and a cylindrical member. A cylindrical space part with at least one end opening and a fluid introduction path opened on the inner peripheral surface of the cylindrical space part, the cylindrical member is disposed in the cylindrical space part of the housing, and has at least one connection with the cylindrical space part. The cylindrical space portion opened at the end in the same direction as the opening direction of the cylindrical space portion and the hole portion opened on the peripheral wall of the cylindrical space portion, the liquid fluid introduced from the fluid introduction path flows into the cylinder of the cylindrical member through the hole portion. A swirl flow is generated in the cylindrical space, and while a gas phase is generated in the center of the swirl flow, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com