Dielectric material for plasma display panel

A technology of dielectric materials and display panels, applied in circuits, discharge tubes, electrical components, etc., to achieve the effect of excellent transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] The dielectric material of the plasma display panel of the present invention will be specifically described below according to the embodiments.

[0067] Tables 1 to 5 show examples (sample Nos. 1 to 19) and comparative examples (sample Nos. 20 to 26) of the present invention, respectively. In addition, sample No. 20 represents the ZnO-B 2 o 3 class of materials.

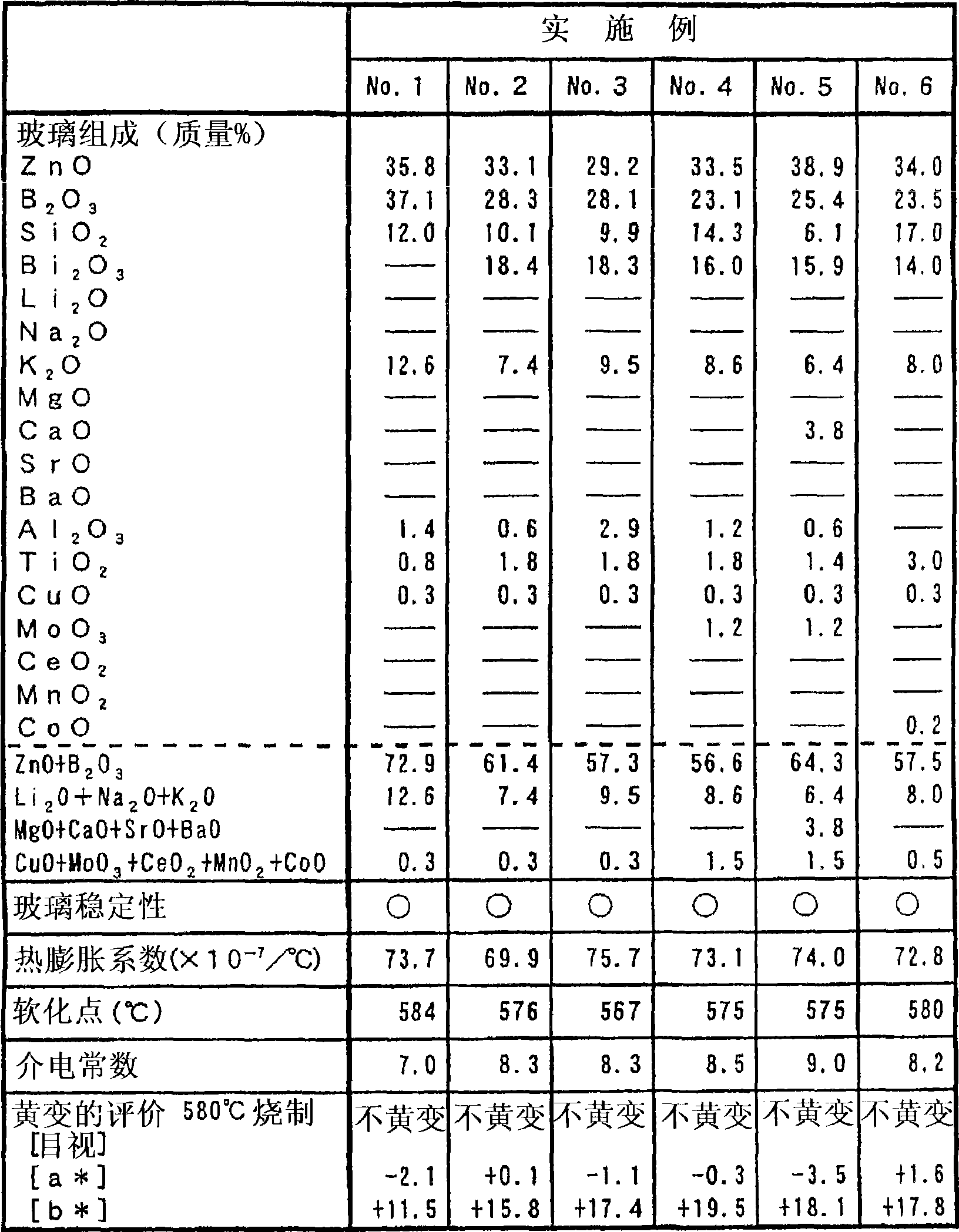

[0068] Table 1

[0069]

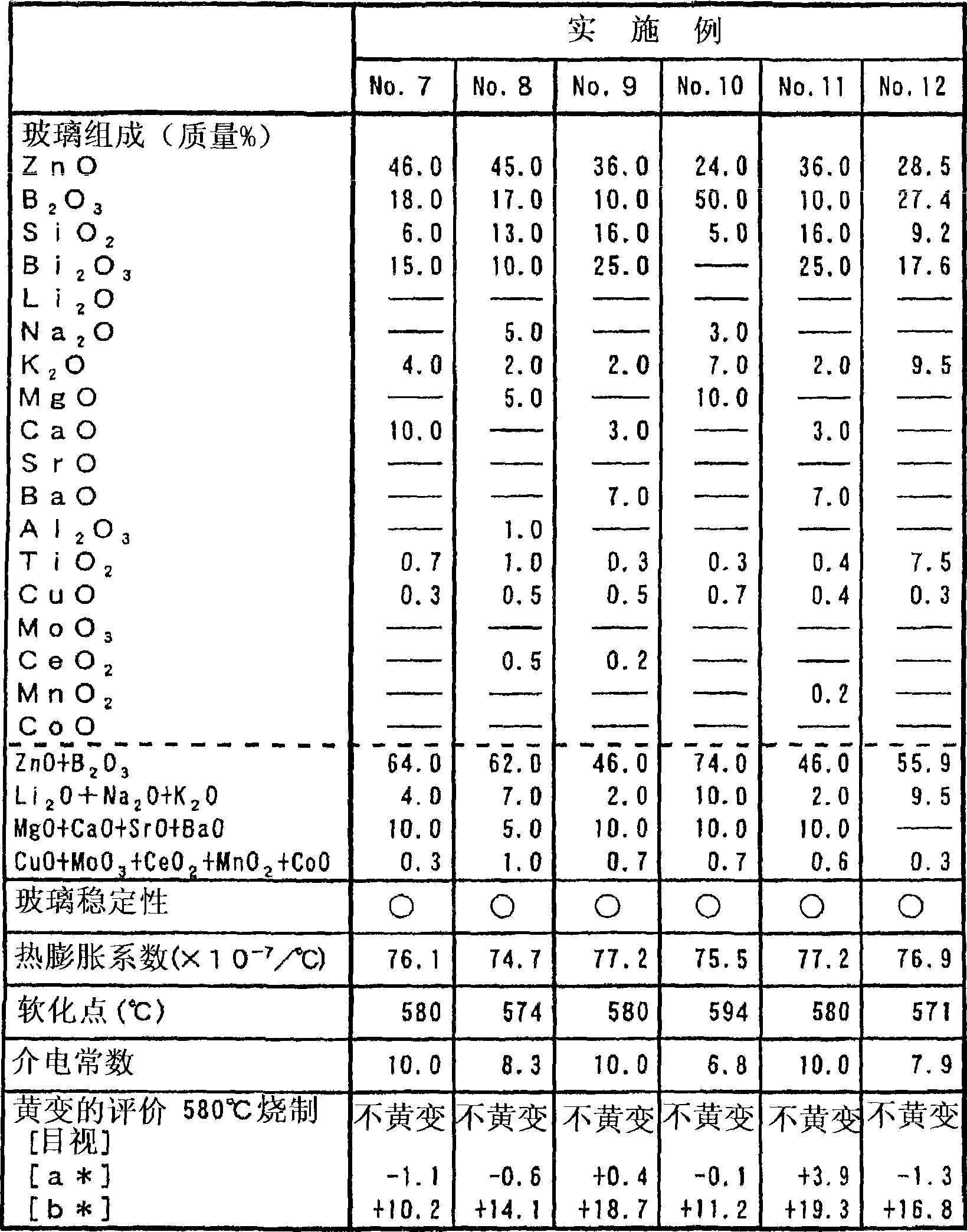

[0070] Table 2

[0071]

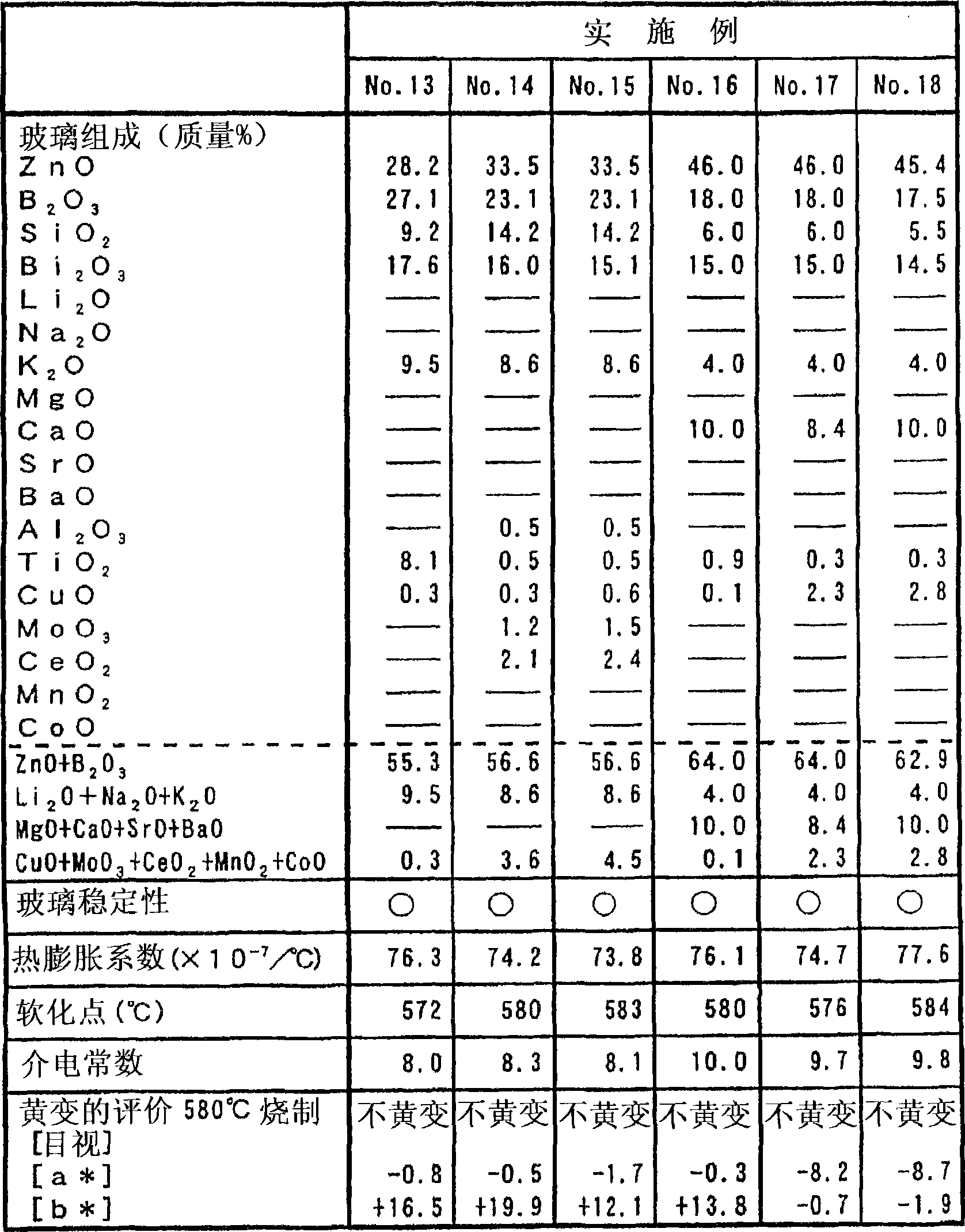

[0072] table 3

[0073]

[0074] Table 4

[0075]

[0076] table 5

[0077]

[0078] Each sample in the table was prepared as follows.

[0079] First, raw materials were mixed and homogenized according to the glass composition shown in the table in mass %. Next, it was placed in a platinum crucible and melted at 1300° C. for 2 hours, and then the molten glass was molded into a thin plate shape. Then, it is pulverized with a ball mill and air-flow classified to obtain the average particle diameter D 50 Below 3.0μm, maximum particle siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com