Brand cigarette flexible tobacco-strips producing grouping process technology

A processing technology and cigarette technology, applied in tobacco, tobacco preparation, application, etc., can solve problems such as unprocessable characteristics and brand style feature selection, and achieve the effect of improving the use value of raw materials, improving product quality, and eliminating fluctuations in processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

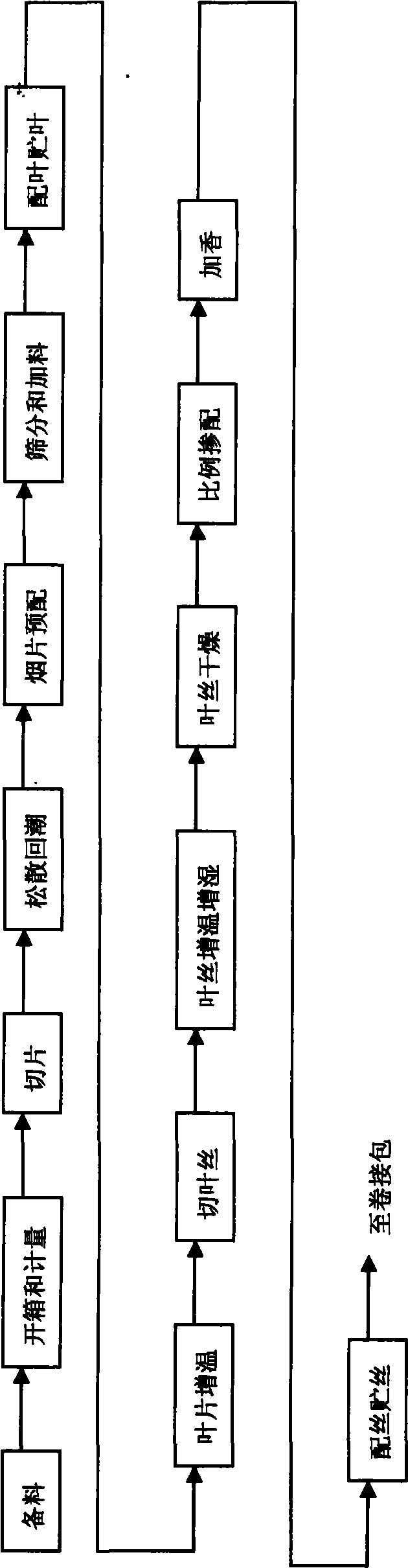

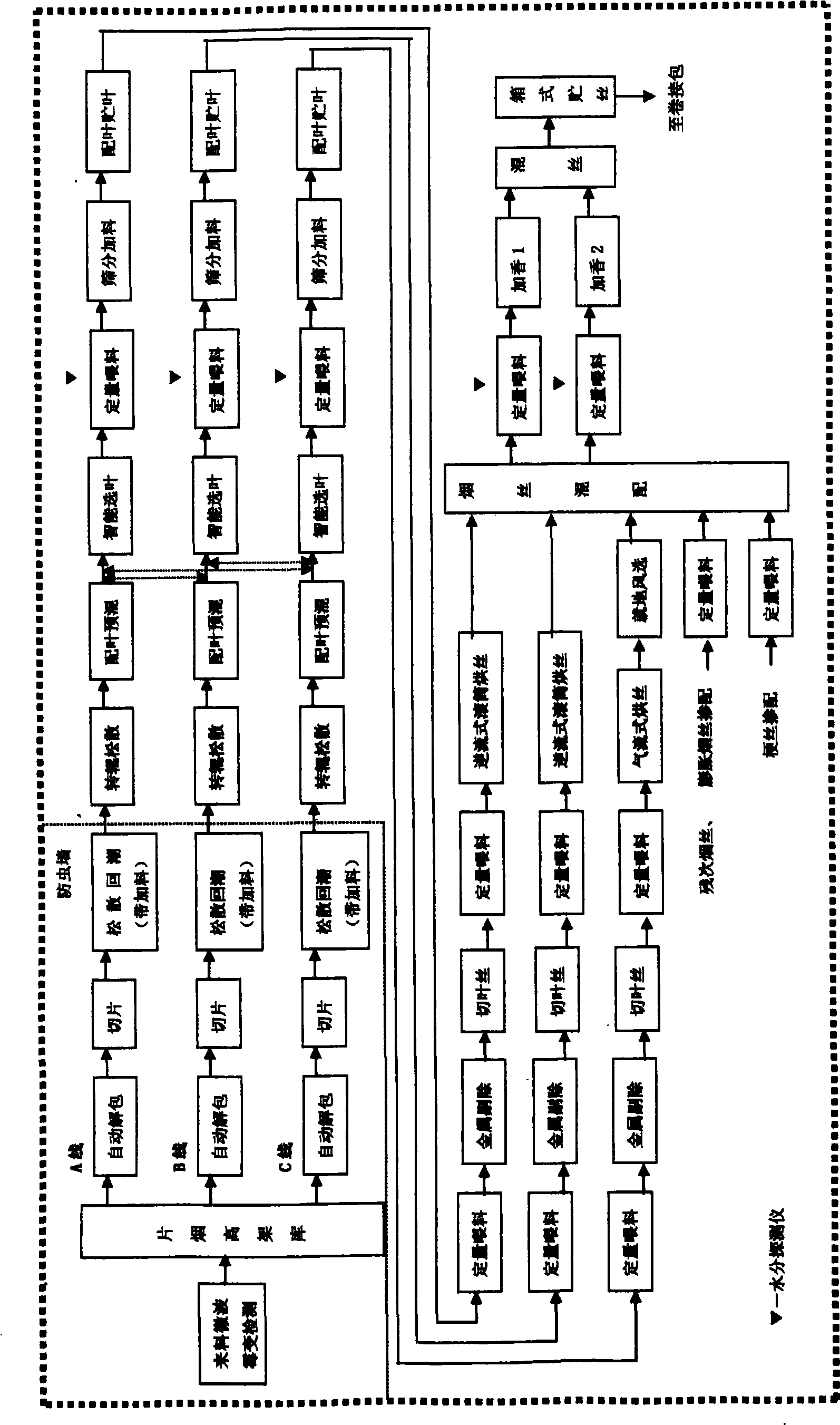

[0034] Brand cigarette flexible shredded group processing technology, please refer to figure 2 ,it includes:

[0035] Step S010, microwave mildew detection step: determine whether the tobacco is mildewed, and remove the tobacco that may be moldy, so as to improve the quality and purity of the incoming tobacco leaves; in this embodiment, microwaves are used to measure the moisture content of the tobacco to determine whether the tobacco is mildewed. Whether mildew occurs;

[0036] Step S020, the step of elevating the tobacco laminar warehouse: sending the laminar tobacco to the elevated warehouse to meet the production turnover of the raw materials of the laminar tobacco;

[0037] Step S100, the step of grouping and preparing materials: divide the tobacco in the high-priced warehouse into three groups and prepare materials. The processing characteristics of the three groups of raw materials are different; the grouping and preparation of materials in this embodiment is automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com