Straight-through choke type cloth bag dust remover

A bag filter and dust collector technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of increasing service life, uneven flow of filter bags, reducing maintenance costs, etc., and prolonging service life. , the structure is simple, the system resistance is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

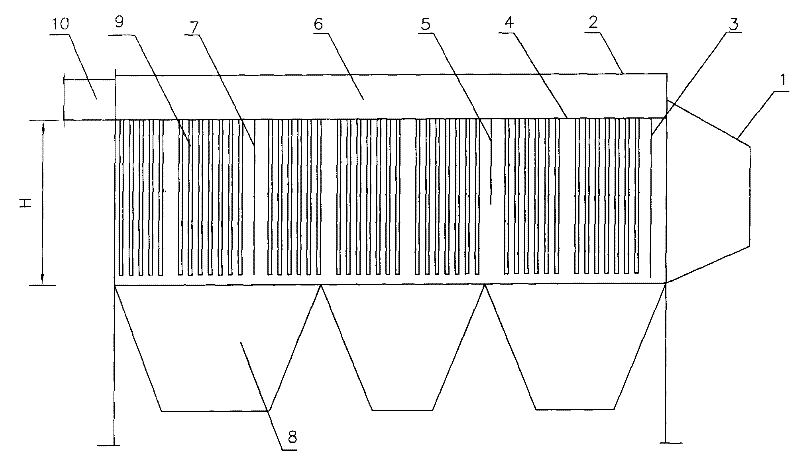

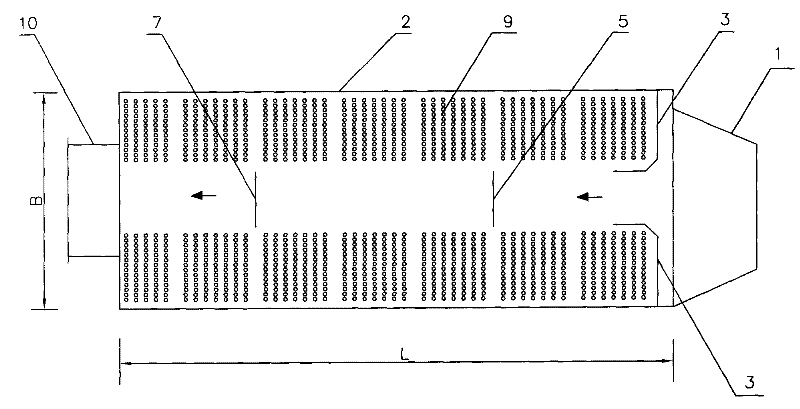

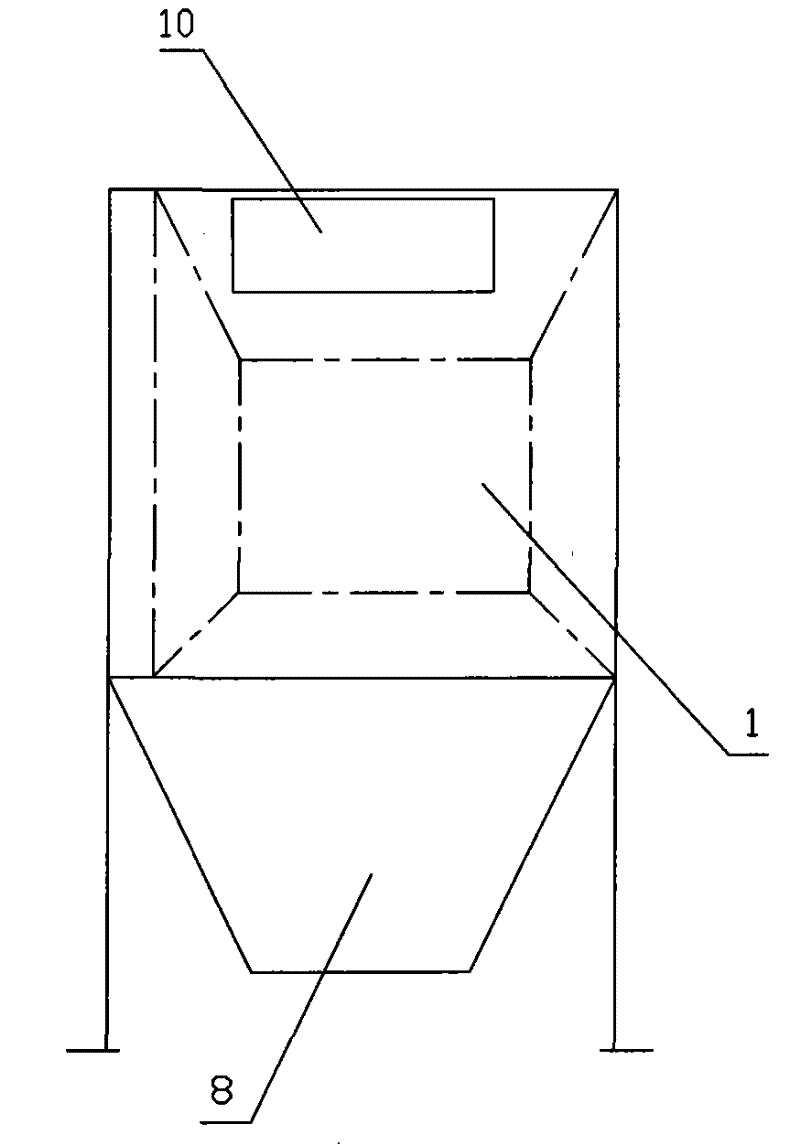

[0022] The straight-through choke bag filter of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments:

[0023] The straight-through choke bag filter shown in the figure has a horizontal dust collector housing 2, one end of the dust collector housing 2 is provided with a trumpet-shaped air inlet 1, and the other end of the dust collector housing 2 is opened at the top. There is a rectangular air outlet 10, and the filter bags 9 arranged in an array are suspended on both sides of the inner cavity bag room of the dust collector housing 2 through the flower plate 4. Above the flower plate 4 is an exhaust chamber 6 communicating with the air outlet 10. Below the filter bag 9 is an ash hopper 8 for receiving dust.

[0024] A pair of L-shaped anti-scour plates 3 are symmetrically arranged on both sides of the entrance of the inner cavity bag room of the dust collector housing 2. The distance between the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com