Catalysis deoxidization process for coal bed gas of coal mine zone

A catalytic deoxidation and coal bed methane technology, applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of methane loss and other problems, achieve the effect of reducing methane cracking, product gas volume reduction, and methane loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

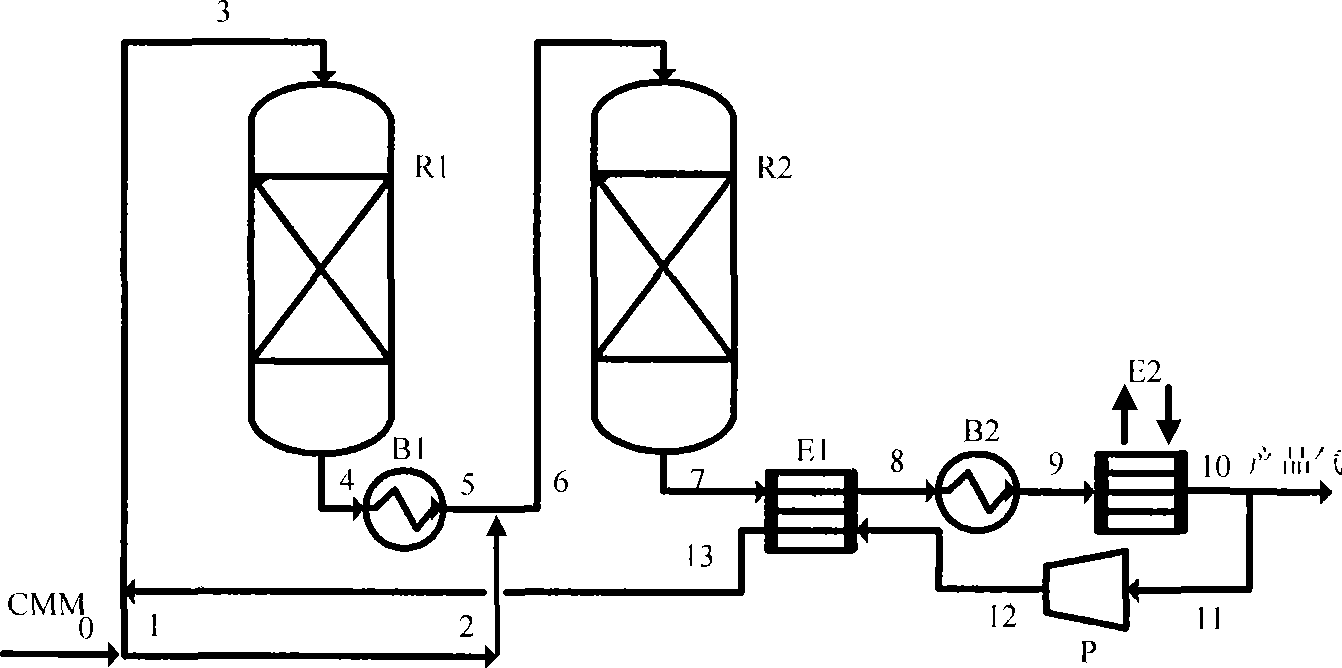

[0032] The catalytic deoxidation reaction process of coalbed methane in the coal mining area of the present embodiment is as follows: figure 1 As shown, a 2-stage catalytic deoxygenation reaction is carried out using a 2-stage reactor:

[0033] The composition of coalbed methane (raw material coalbed methane) in coal mining area is (vol%): CH 4 50, O 2 10.5, N 2 39.5. Air volume is 30000Nm 3 / h, temperature 120℃, pressure 0.6MPa.

[0034] The raw coalbed methane is divided into two parts (12000Nm 3 / h and 18000Nm 3 / h) enter the first and second stage reactors respectively:

[0035] 40% of the total amount of raw coalbed methane is 12000Nm 3 / h (raw coalbed methane 0) into line 1, with 24000Nm from line 13 3 / h (temperature 422°C) return gas mixing, O in the gas after mixing 2 The content is 3.5%, the temperature is 330 ° C, and it enters the first-stage reactor R1 through pipeline 3, and under the action of the catalyst, the first-stage catalytic deoxygenation ...

Embodiment 2

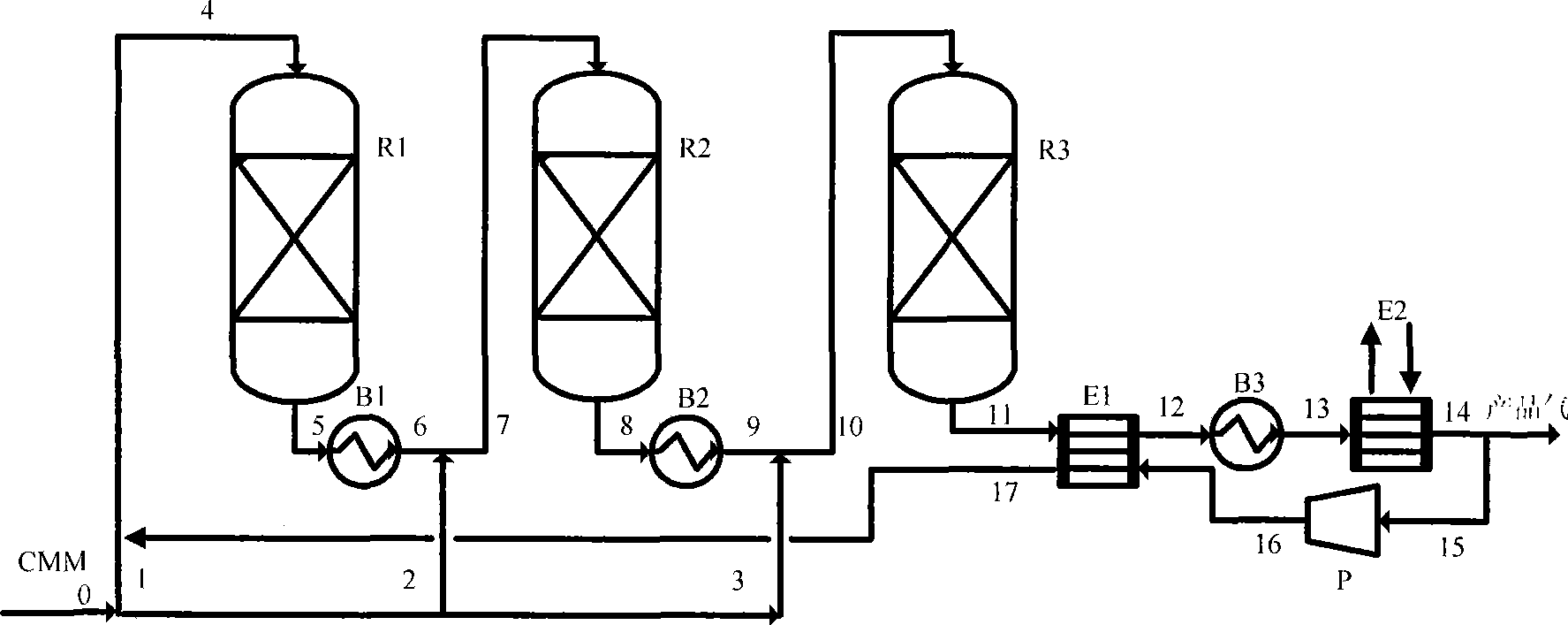

[0040] The catalytic deoxidation reaction process of coalbed methane in the coal mining area of the present embodiment is as follows: figure 2 As shown, a 3-stage catalytic deoxygenation reaction was carried out using a 3-stage reactor:

[0041] The composition of coalbed methane (raw material coalbed methane) in coal mining area is (vol%): CH 4 50, O 2 10.5, N 2 39.5. Air volume is 30000Nm 3 / h, temperature 120℃, pressure 0.6MPa.

[0042] The raw coalbed methane is divided into three parts (respectively 7500Nm3 / h, 10500Nm 3 / h and 12000Nm 3 / h) Enter the first, second and third stage reactors respectively:

[0043] 7500Nm for the first part 3 / h Raw CBM 0 enters line 1, with 15000Nm from line 17 3 / h (temperature 422°C) return gas mixing, O in the gas after mixing 2 The content is 3.5%, and the temperature is 330 ° C. It enters the first-stage reactor R1 through the pipeline 4, and under the action of the catalyst, the first-stage catalytic deoxygenation reac...

Embodiment 3

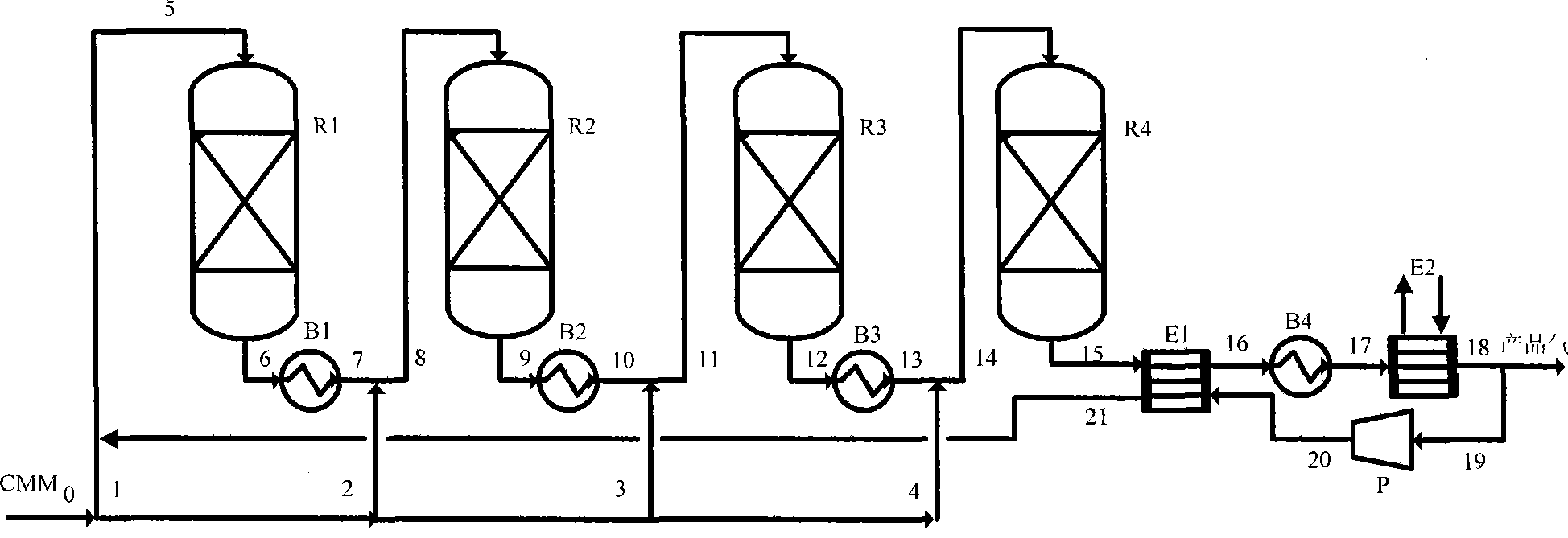

[0049] The catalytic deoxidation reaction process of coalbed methane in the coal mining area of the present embodiment is as follows: image 3 As shown, a 4-stage catalytic deoxygenation reaction is carried out using a 4-stage reactor:

[0050] The composition of coalbed methane (raw material coalbed methane) in coal mining area is (vol%): CH 4 50, O 2 10.5, N 2 39.5. Air volume is 30000Nm 3 / h, temperature 120℃, pressure 0.6MPa.

[0051] The raw coalbed methane is divided into four parts (respectively 4500Nm 3 / h, 6000Nm 3 / h, 9000Nm 3 / h and 10500Nm 3 / h) Enter the first, second, third and fourth stage reactors respectively:

[0052] 4500Nm for the first part 3 / h Raw CBM 0 enters line 1, with 9000Nm from line 21 3 / h (temperature 421°C) return gas mixing, O in the gas after mixing 2 The content is 3.5%, and the temperature is 330 ° C. It enters the first-stage reactor R1 through the pipeline 5, and under the action of the catalyst, the first-stage catalytic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com