Shelf beam support -free construction method for edge span beam section of large-span steel case beam stayed-cable bridge

A steel box girder, large-span technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as not being well solved, and achieve the effect of good economy, simple and practical method, and shortened construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

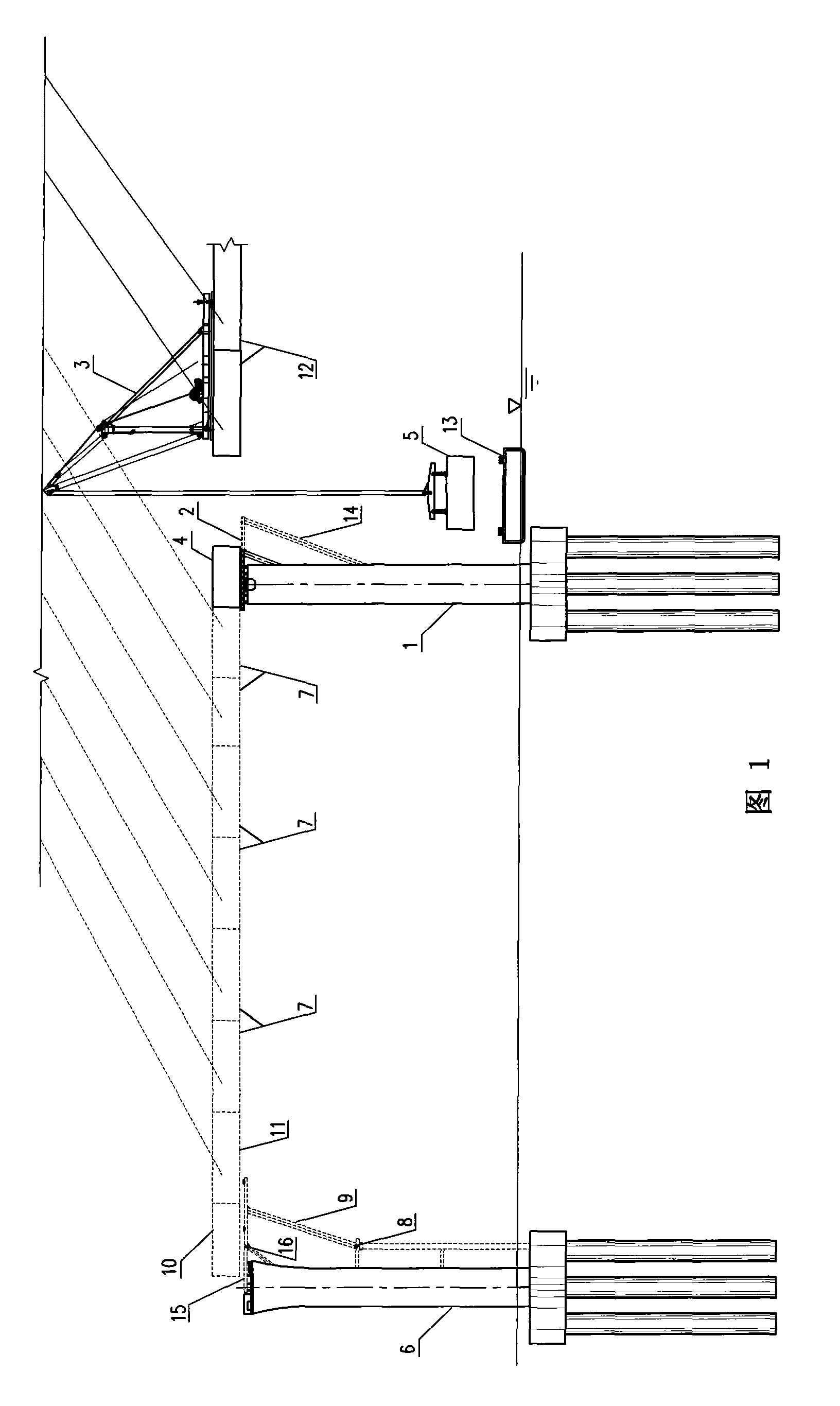

[0031] Such as figure 1 As shown, the method for the construction of the side span beam section of the long-span steel box girder cable-stayed bridge of the present invention without a beam support, its construction steps are as follows:

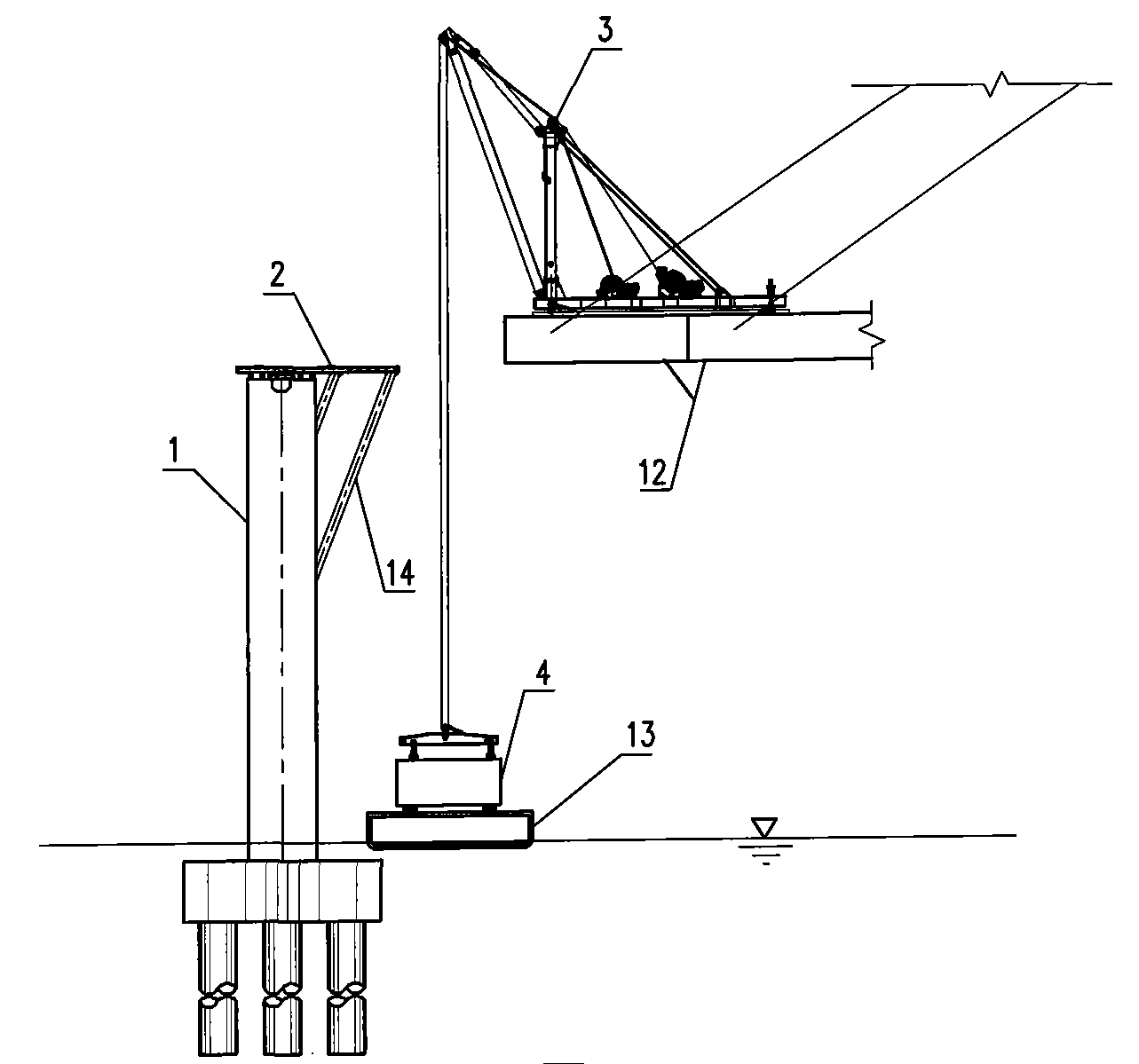

[0032] (1) Set up a small temporary support 2 on the top of the auxiliary pier 1, lift the steel box girder section 4 on the top of the auxiliary pier 1 and place it on the small temporary support 2 and the top of the auxiliary pier 1,

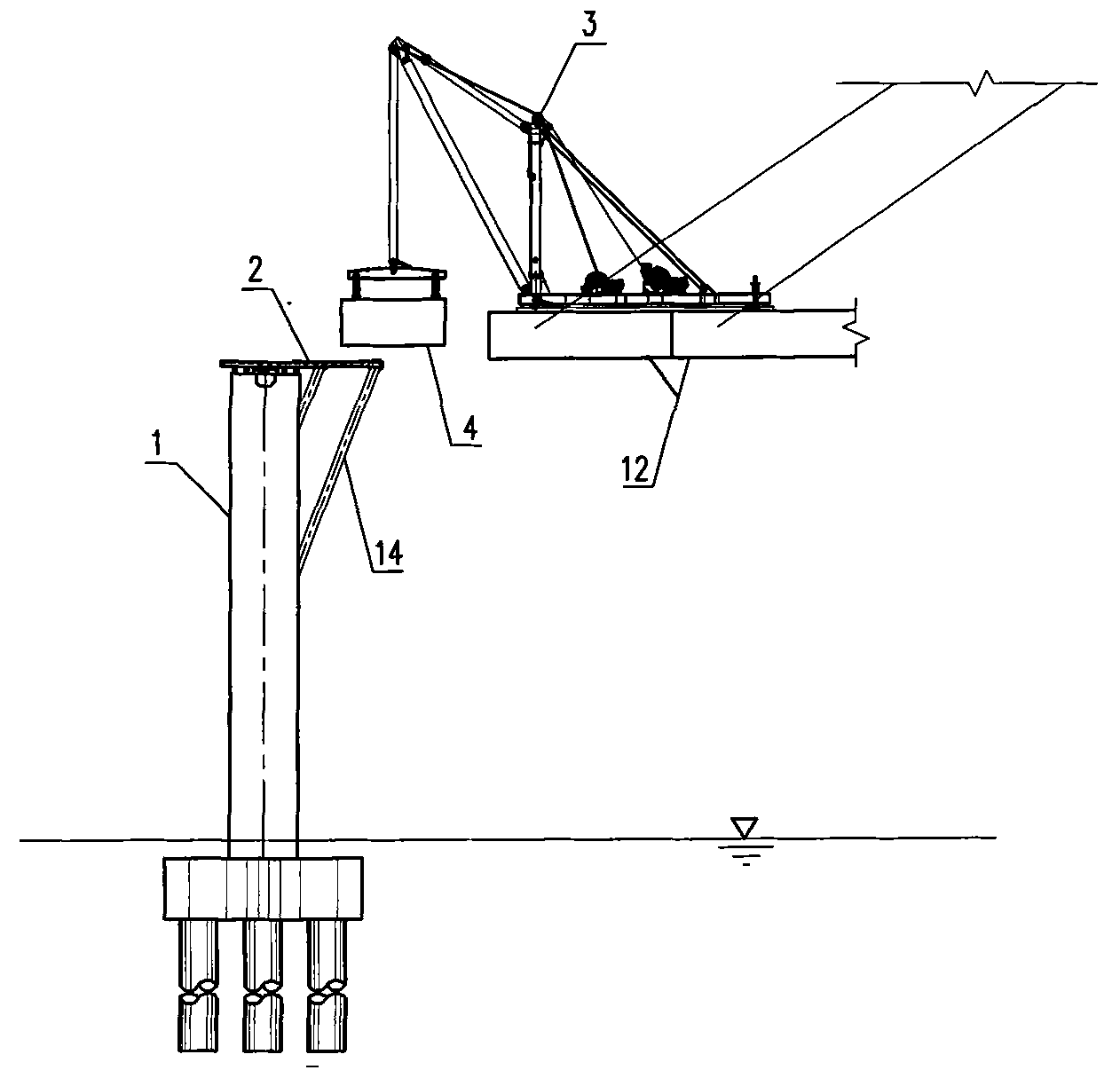

[0033] (2) Remove a part 14 of the small temporary support 2 on the river center side, lift the steel box girder section 5 adjacent to the auxiliary pier 1 on the river center side and complete the installation and cable hanging,

[0034] (3) Put the steel box girder section 4 on the top of the auxiliary pier 1 in place and complete the corresponding connection and installation,

[0035] (4) Complete the hoisting construction of the side-span standard steel box girder section 7 of the auxiliary pier 1 and t...

Embodiment 2

[0043] Such as Figure 1-13 As shown, the method for the construction of the side-span girder section of the long-span steel box girder cable-stayed bridge of the present invention without a beam support, except that the construction step (1) is to push and move the auxiliary pier 1 pier top steel box girder section 4 to On the small temporary support 2 and the top of the auxiliary pier 1, the construction step (5) is to push and move the steel box girder section 10 on the top of the junction pier 6 to the top of the rear temporary support 15 and outside the top of the junction pier 6, and the rest are connected with Example 1 is the same.

Embodiment 3

[0044] Embodiment 3: the method for the construction of the side-span girder section of the long-span steel box girder cable-stayed bridge of the present invention without the beam support, except that the construction step (5) is to rotate the lower horizontal rotary hinge 8 and the upper horizontal rotary hinge 16 to make the front temporary The support 9 is located in the direction of the bridge, providing enough operating space for the hoisting of the steel box girder section 11 adjacent to the junction pier 6 on the river center side, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com