Control method for improving smoothening capability of excavator

A control method and excavator technology, which is applied in the direction of earth mover/excavator, construction, etc., can solve the difficulty of reasonably determining the size of the orifice, occupying the control main valve control pipeline, increasing the complexity of pipeline control, etc. problems, achieve the best leveling performance, reduce production and maintenance costs, and achieve good leveling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

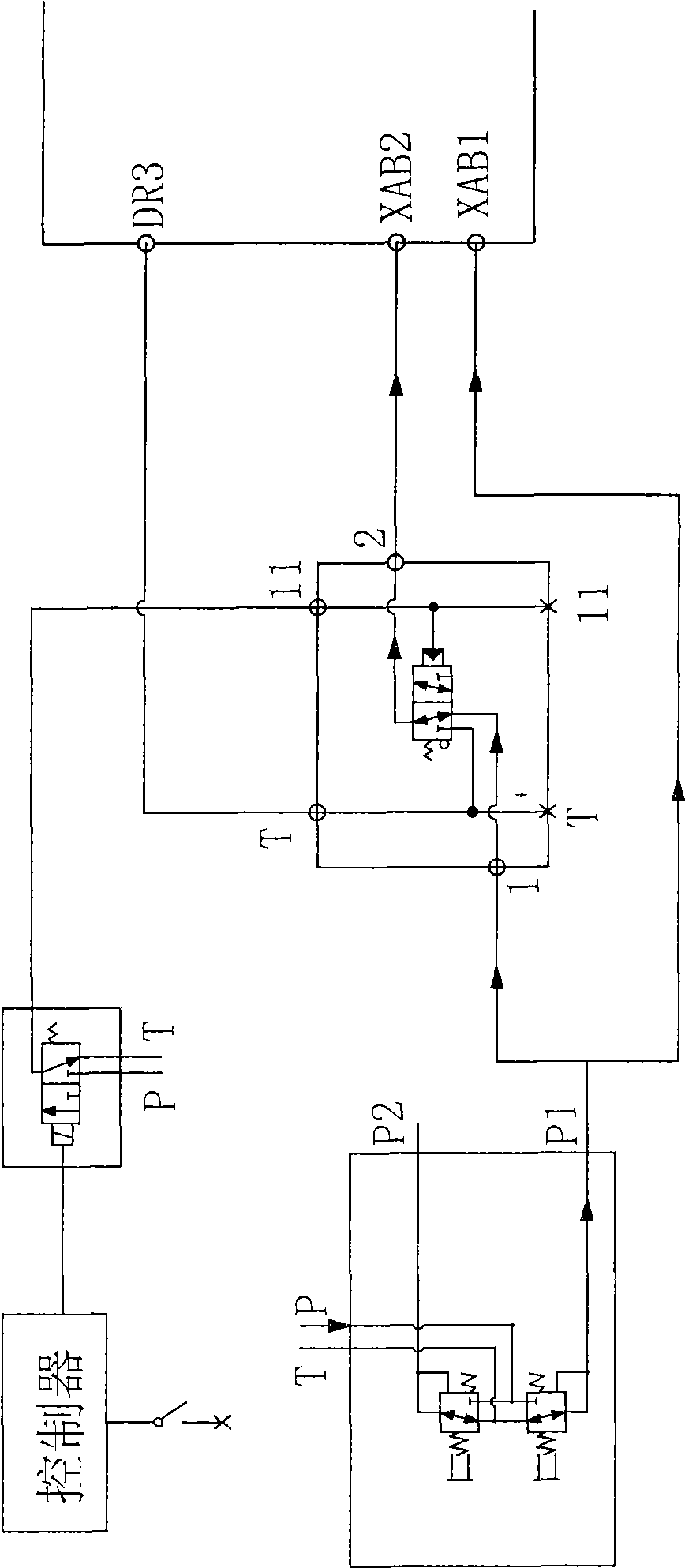

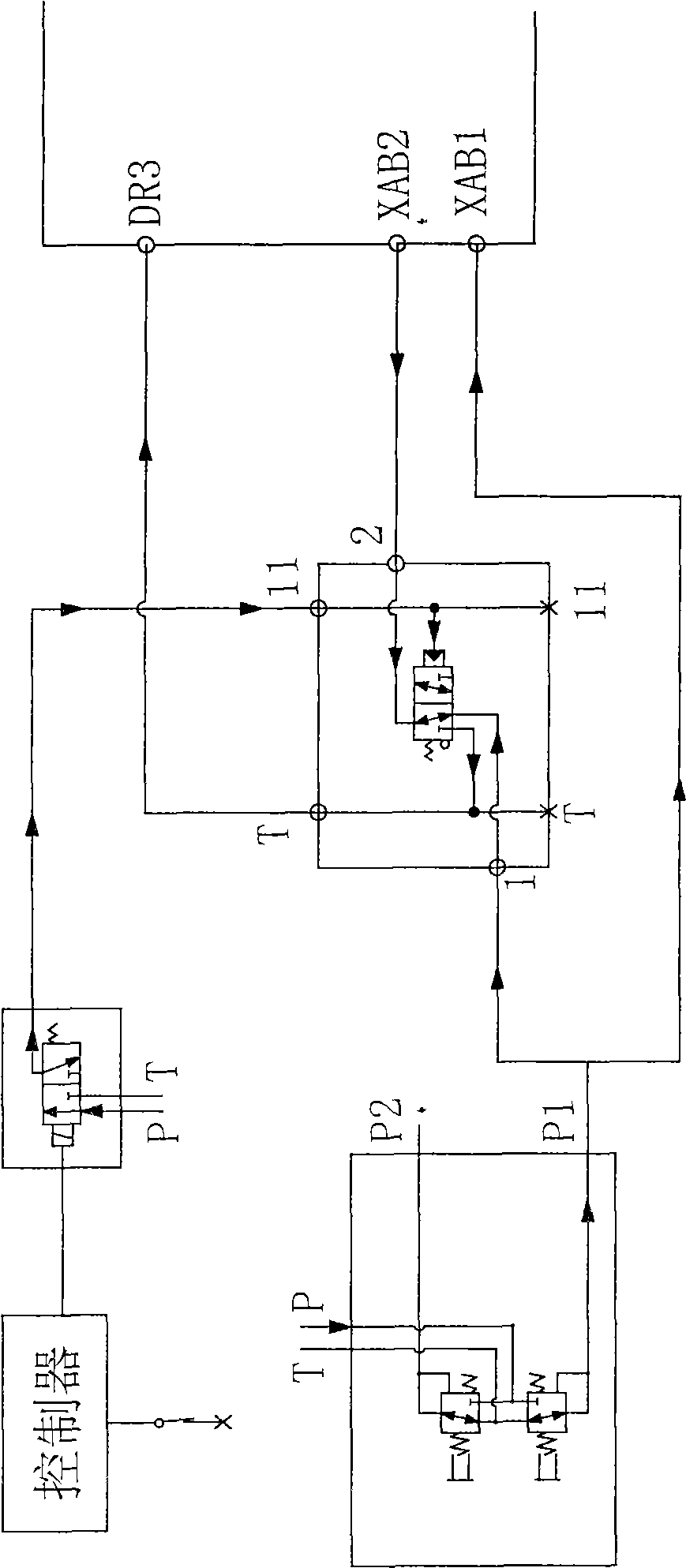

[0020] Example 1: see Figure 1 to Figure 2 As shown, a control method for improving the leveling performance of an excavator is provided with a hydraulic control directional valve on the boom confluence circuit in the hydraulic circuit of the excavator, and the control end 11 of the hydraulic control valve is connected to a solenoid valve, The control end of the solenoid valve is connected to the controller, such as figure 1 As shown, the input pin 1 of the hydraulic control directional valve is connected to the output pin P1 of the boom pilot valve in the confluence circuit, and its output pin 2 is connected to the boom confluence spool XAB2 pin in the confluence circuit, at the pilot valve output end The P1 pin is connected in parallel with an oil delivery line at the same time, which is connected to the XAB1 pin of the main valve core port of the boom, and the oil return end T of the hydraulic control directional valve is connected to the main valve oil return DR3 pin.

[002...

Embodiment 2

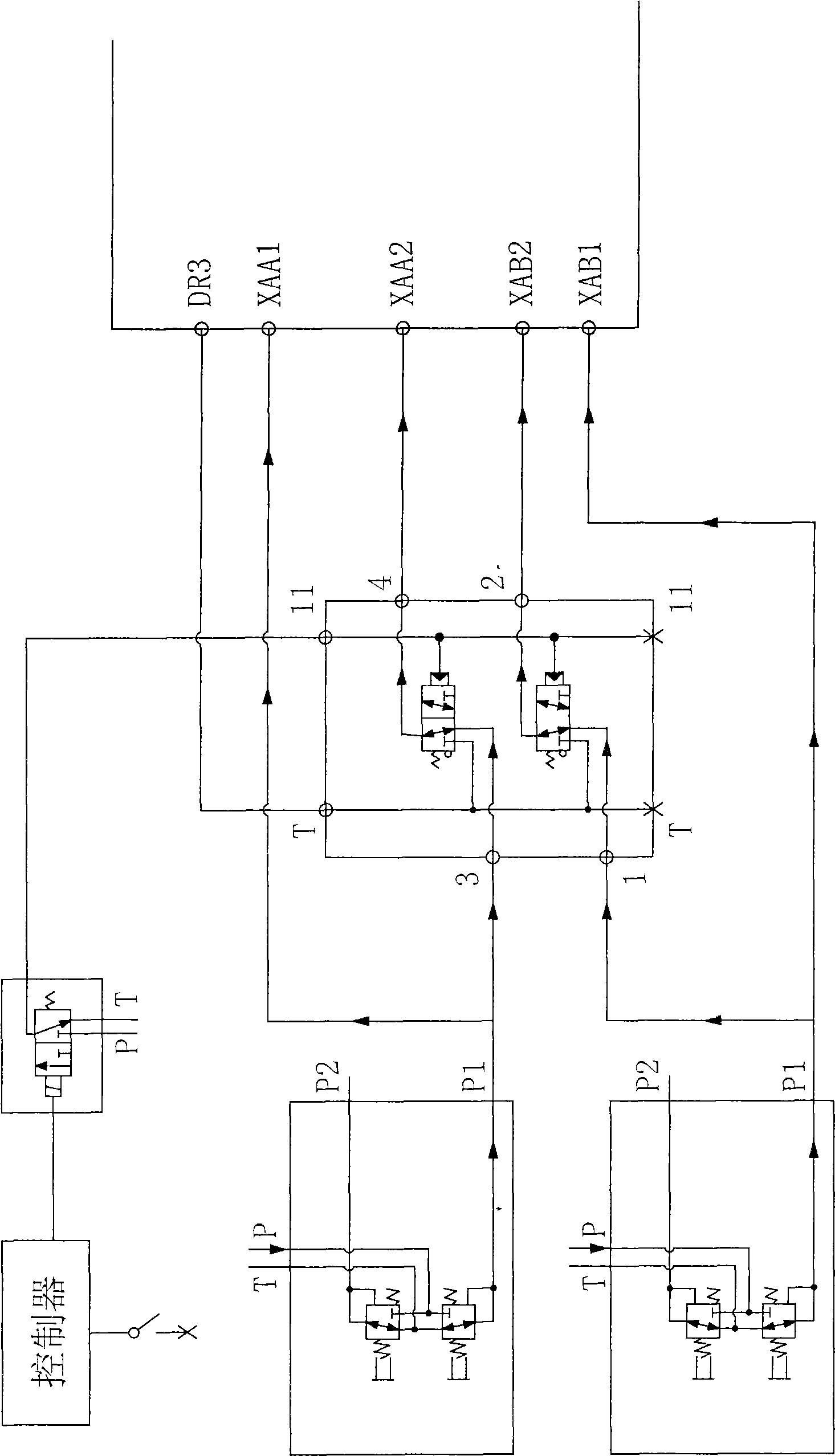

[0022] Example 2: see Figure 3 to Figure 4 As shown, a control method for improving the leveling performance of an excavator is provided with a hydraulic control directional valve on the boom confluence circuit and the stick excavation confluence circuit in the hydraulic circuit of the excavator. The control end of the hydraulic control valve is 11 feet Connected to a solenoid valve, the control end of the solenoid valve is connected to the controller, such as image 3 As shown, the hydraulic control directional valve is provided with a reversing valve connected in series with the boom confluence circuit and the stick excavation confluence circuit. The control end is connected in parallel to form the control end 11 feet, and the hydraulic control directional valve input end 1 foot and the confluence circuit The output of the middle boom pilot valve is connected to the P1 pin, the input 3 is connected to the stick digging pilot valve output P1 in the confluence loop, and the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com