Non-damage drilling head

A non-damage, drill bit technology, applied to drilling equipment, drill bits, drilling tools, etc., can solve the problem of damage to metal pipe networks, achieve high practicability, improve alarm accuracy, and improve detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

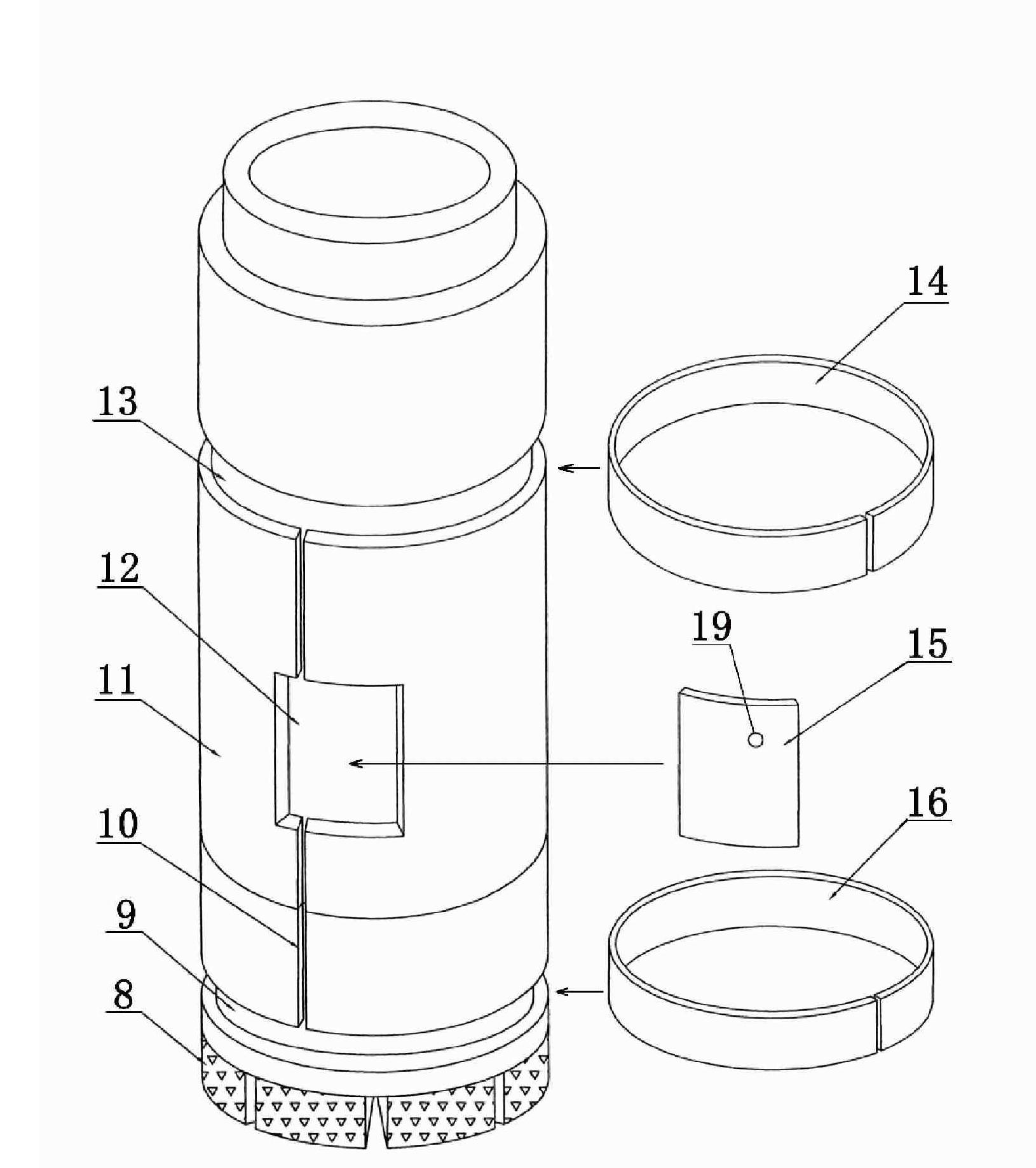

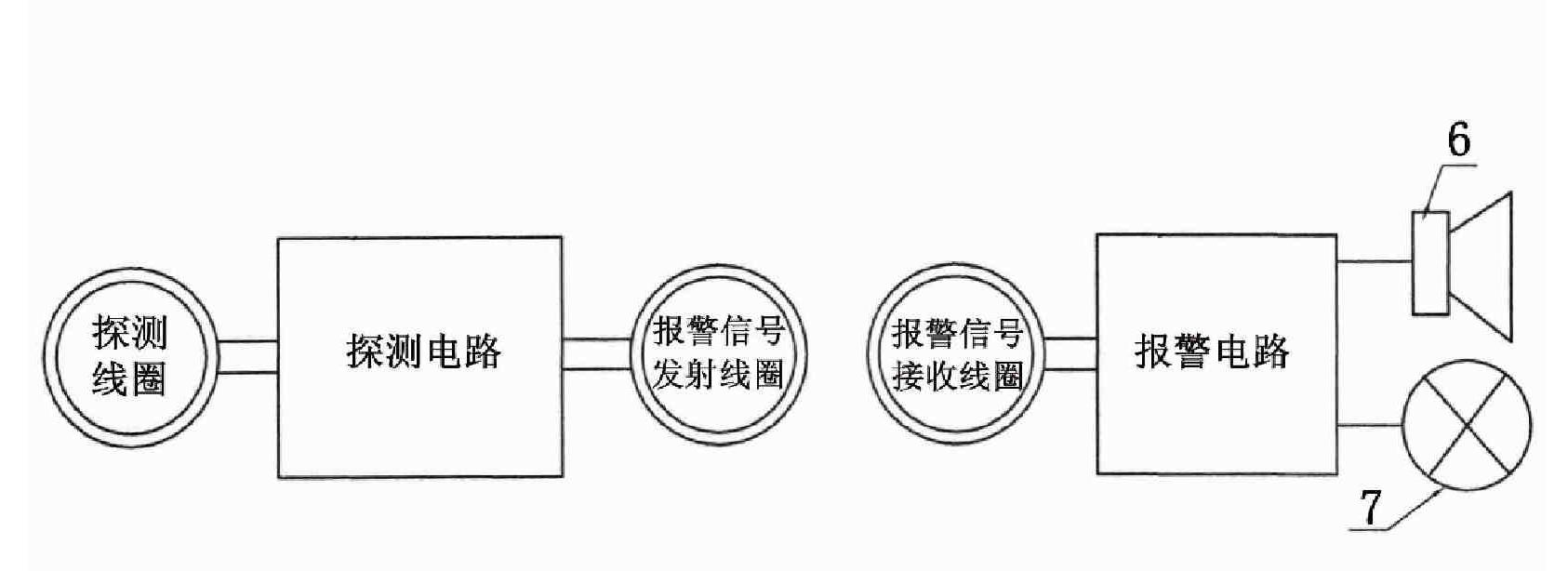

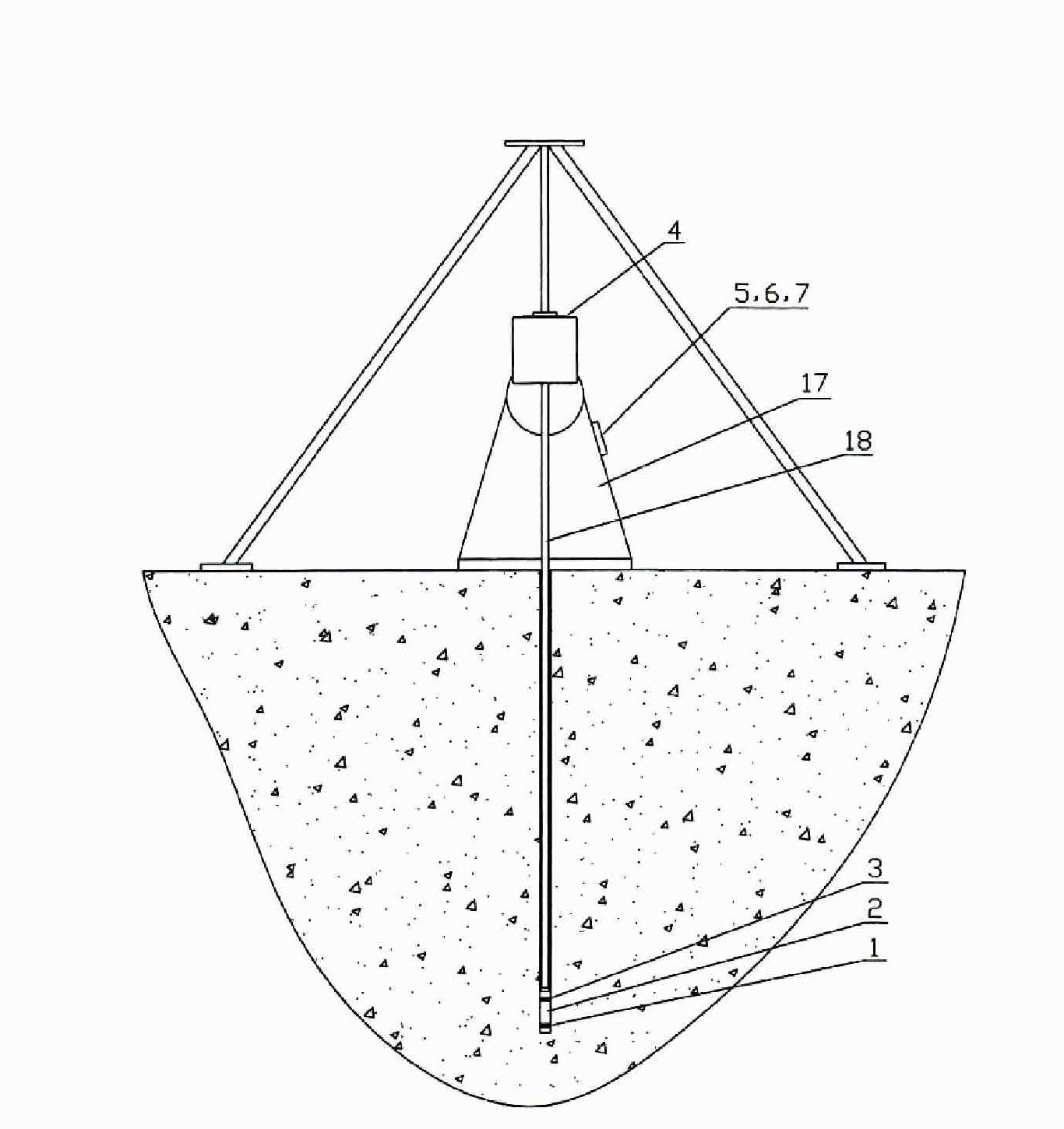

[0025] see figure 1 , figure 2 As shown, the non-damage drilling equipment is divided into two parts: a. the detection coil 1 on the drilling tool, the detection circuit board 2, and the alarm signal transmitting coil 3; b. the alarm signal receiving coil 4 on the ground, the alarm circuit 5, Buzzer 6, warning light 7.

[0026] see figure 1 As shown, the drill bit 8 is connected with the short-circuit 11, and there is an annular detection coil groove 9 on the bottom of the drill bit 8, and the detection coil 1 is placed in the groove; the short-circuit 11 has a detection circuit board groove 12, and the detection circuit board 2. Put it in the groove; the cover plate 15 is fixed on the notch, and the gap is glued to the surface until the surface is flat, and there is a small hole 19 for placing the circuit control switch on the cover plate 15;

[0027] The upper part of the short-circuit 11 is provided with an annular alarm transmitter coil slot 13 for placing the alarm tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com