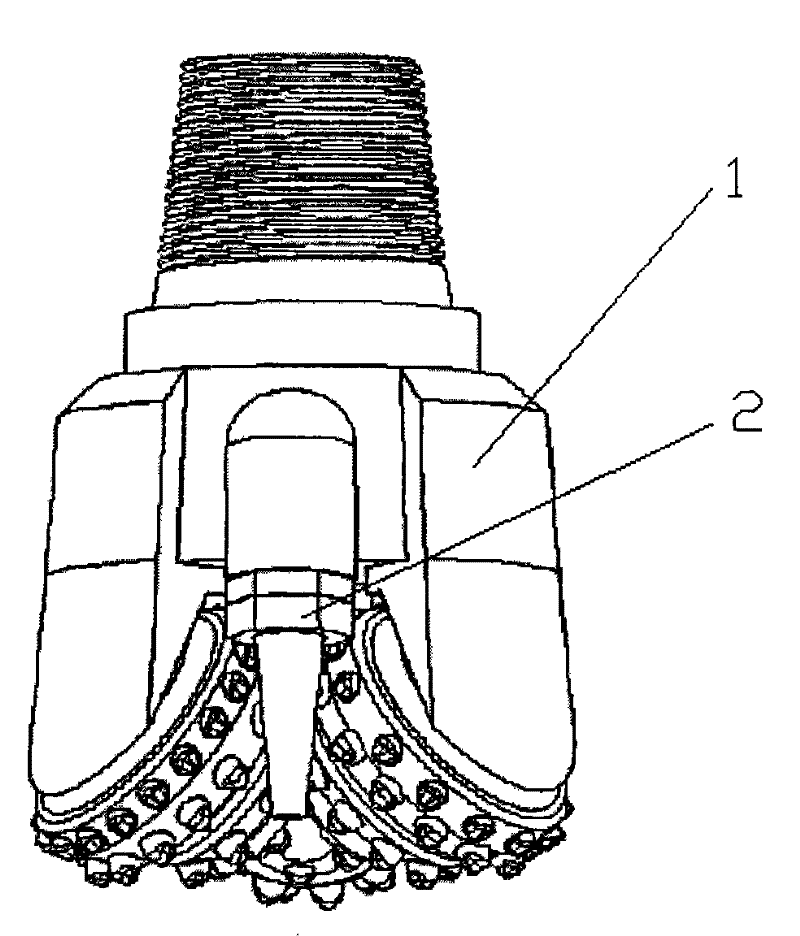

Drill with flexible nozzle

A flexible nozzle and drill bit technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling and production, etc., to achieve the effects of strong impact, easy positioning and injection, and increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

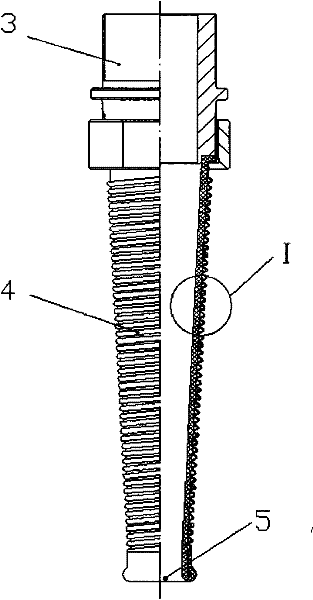

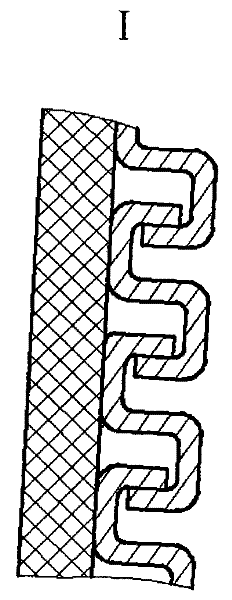

[0032] Example 2:

[0033] The flexible nozzle 2 is installed on the drill bit 1 . The flexible nozzle 2 is composed of a joint 3 and a flexible nozzle 4, the flexible nozzle 4 is connected with the joint 3, and the joint 3 is connected with the nozzle hole of the drill bit 1. The flexible nozzle 2 is a tubular structure, on which there is a drilling fluid injection hole 5 that communicates the inner flow channel of the drill bit with the outer space of the drill bit. The flexible nozzle 4 is composed of a rubber hose, a corrugated metal hose, and a wire or metal strip braided mesh sleeve. The corrugated metal hose is a continuous thin-walled tube with strong plasticity, so the flexible nozzle 4 also has strong plasticity. In this way, the nozzle has the characteristic that the outlet orientation can be adjusted. This kind of flexible nozzle 2 can be elastically or plastically deformed when being bumped, and is not prone to breakage, so it can also ensure high reliability w...

Embodiment 2

[0035] Example 3:

[0036]The flexible nozzle 2 is installed on the drill bit 1 . The flexible nozzle 2 is composed of a joint 3 connected with the drill bit 1 and a flexible nozzle 4, the flexible nozzle 4 is connected with the joint 3, and the joint 3 is connected with the nozzle hole of the drill bit 1. The flexible nozzle 2 is a tubular structure, on which there is a drilling fluid injection hole 5 that communicates the inner flow channel of the drill bit with the outer space of the drill bit. The flexible nozzle 4 consists of a wire-reinforced composite hose with a rubber or plastic matrix. This composite material hose has strong elasticity, so the flexible nozzle 4 also has strong elasticity. When the flexible nozzle 2 on the drill bit is bumped during operation, plastic deformation and fracture are unlikely to occur even if a large deformation occurs. Therefore, even if the length of the nozzle body is relatively large, it can have significantly higher operational re...

Embodiment 3

[0038] Example 4:

[0039] The flexible nozzle 2 is installed on the drill bit 1 . Flexible nozzle 2 is made up of joint 3, flexible nozzle 4 and rigid nozzle 6, and rigid nozzle 6 links to each other with the lower end outlet of flexible nozzle 4, and flexible nozzle 4 links to each other with joint 3, and joint 3 links to each other with the nozzle hole of drill bit 1. The flexible nozzle 2 is a tubular structure, on which there is a drilling fluid injection hole 5 that communicates the inner flow channel of the drill bit with the outer space of the drill bit. Flexible nozzle 4 has a section of rubber hose or plastic hose, and the outlet end of rubber hose or plastic hose is equipped with hard alloy rigid nozzle 6. Carbide rigid nozzles have high wear resistance and erosion resistance, so this flexible nozzle has strong erosion resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com