Passive jet method and device for enhancing vertical shaft wind mill performance

A wind turbine, vertical axis technology, applied to wind turbines, wind turbines, wind turbine components and other directions at right angles to the wind direction, can solve problems such as energy consumption, and achieve the effects of reducing starting wind speed, stable effect, and improved power coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

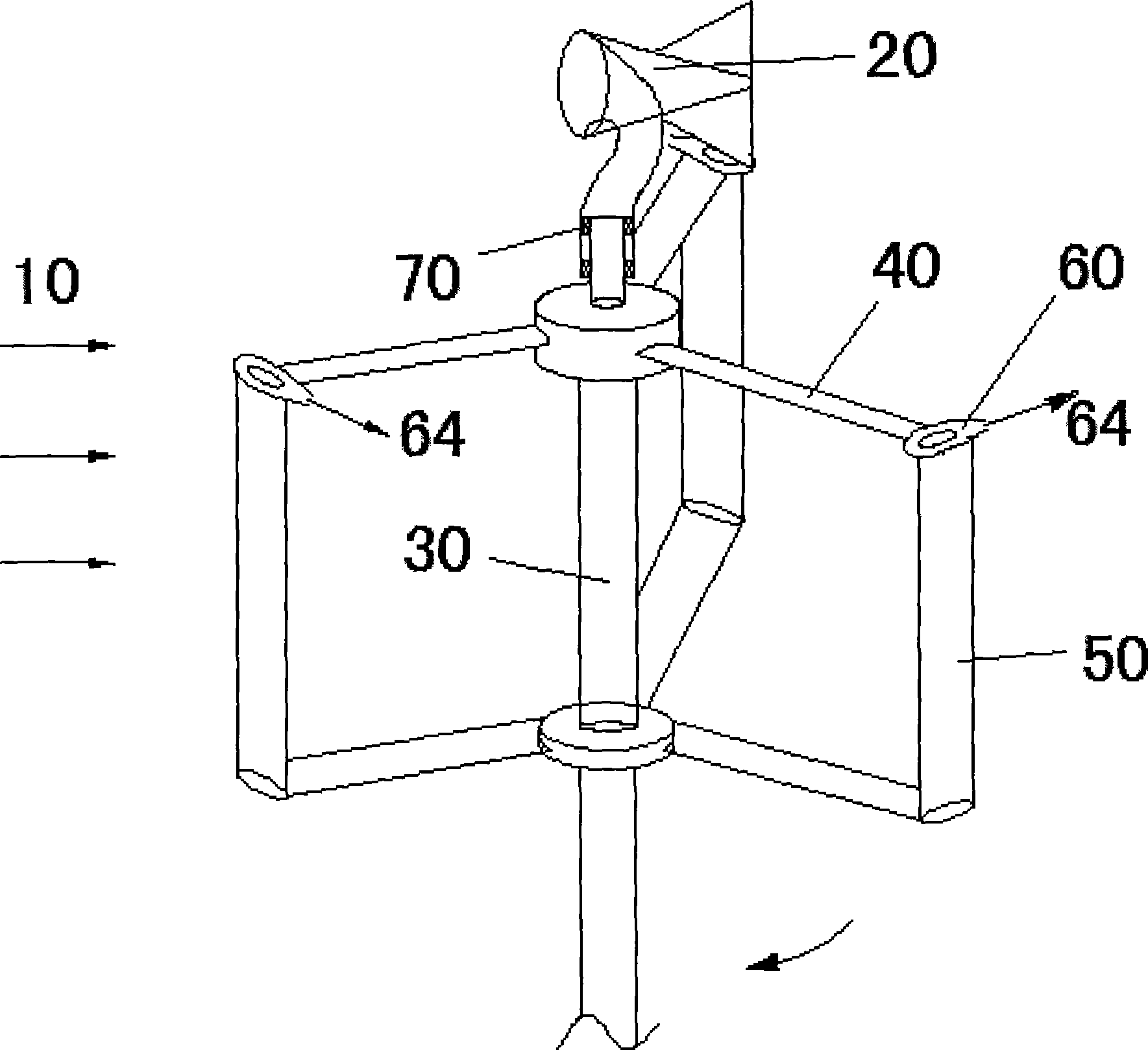

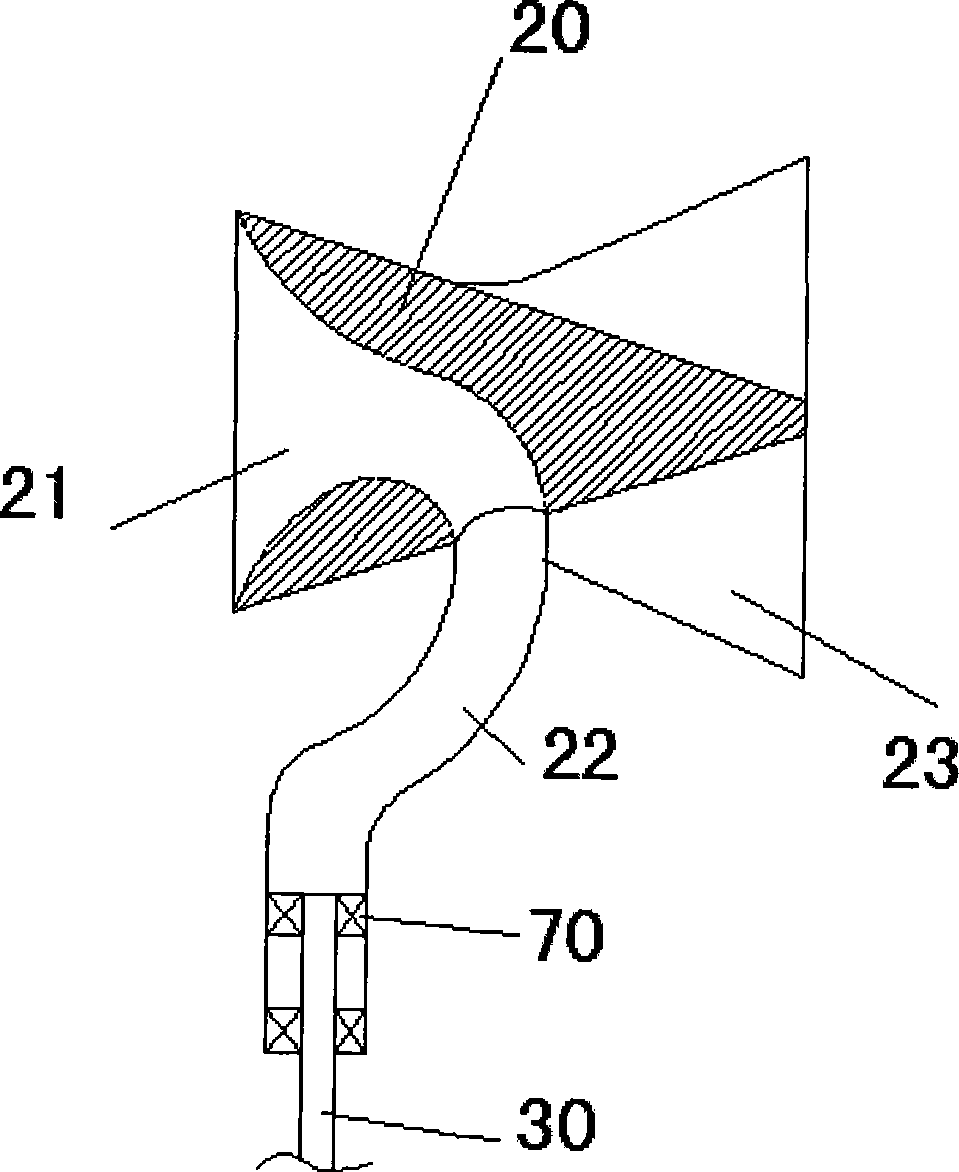

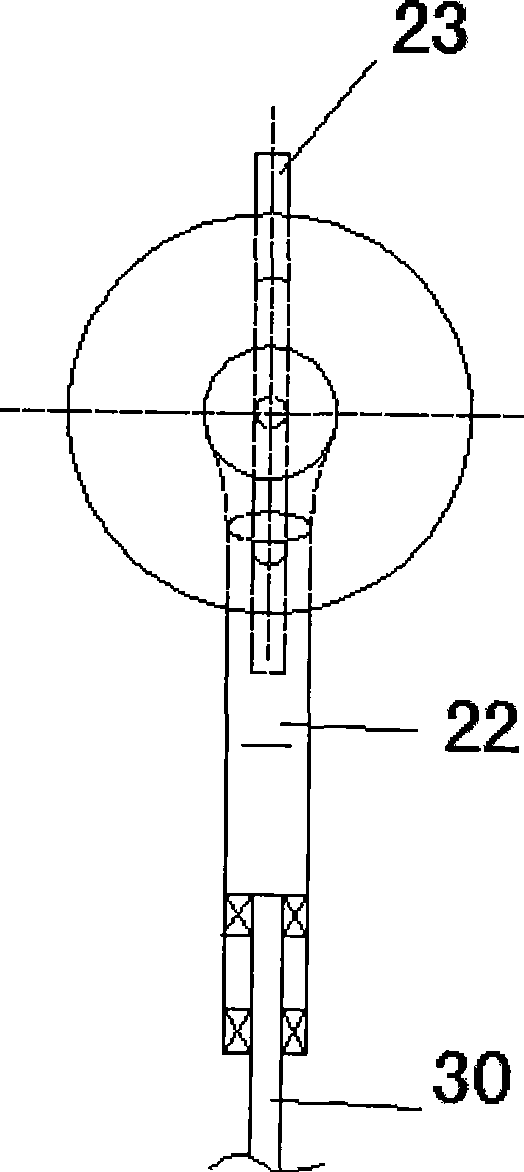

[0024] refer to figure 1 , the wind wheel of the wind turbine in the present invention is composed of blades 50, blade support rods 40, vertical shaft 30, air intake device 20 and exhaust device 60, the air intake device 20 is set with the vertical shaft 30 through the bearing 70, and can be aligned at any time Wind direction; vertical shaft 30, support rod 40, blade 50 and exhaust device 60 are all hollow, and as air flow channel, there are holes identical with the number of support rod 40 on the pipe wall of vertical shaft 30, and their holes communicate, and Reliable connection; the exhaust device 60 connects the blades 50 and the support rods 40 respectively; the holes on the support rods 40 communicate with the holes on the exhaust device 60 to form jets 64 in the opposite direction of wind turbine rotation. The natural wind 10 blows the vertical axis wind turbine to rotate and do work. After the natural wind 10 enters the air intake device 20, it enters the hollow verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com