Axial-symmetry inner parallel turbine-based rotary detonation ramjet combined engine and control method

A turbine engine and ramjet technology, which is applied in combined engines, ramjet engines, mechanical equipment, etc., can solve the problems of enhanced ramjet combined cycle engines with high integration, complex structure and control system, slow combustion wave propagation speed, etc. , to achieve the effect of broadening the lower limit of the working Mach number, expanding the working range and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

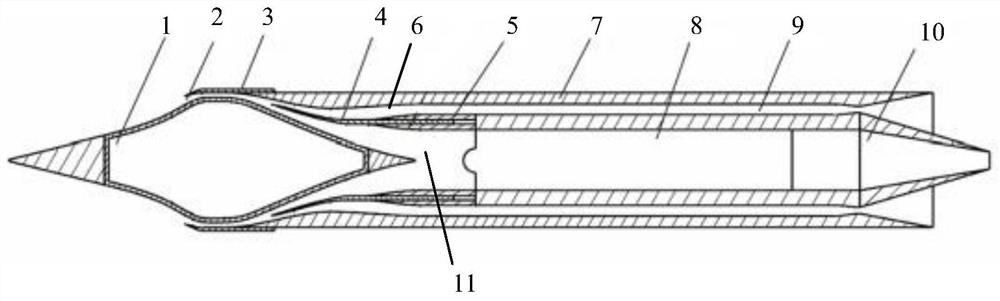

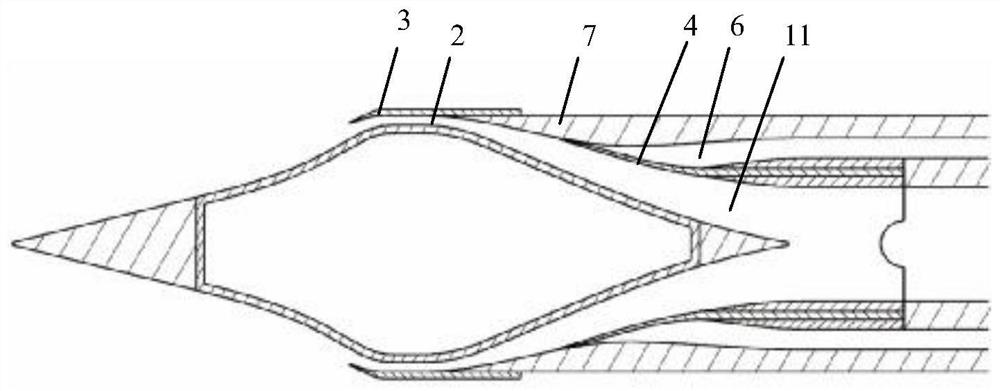

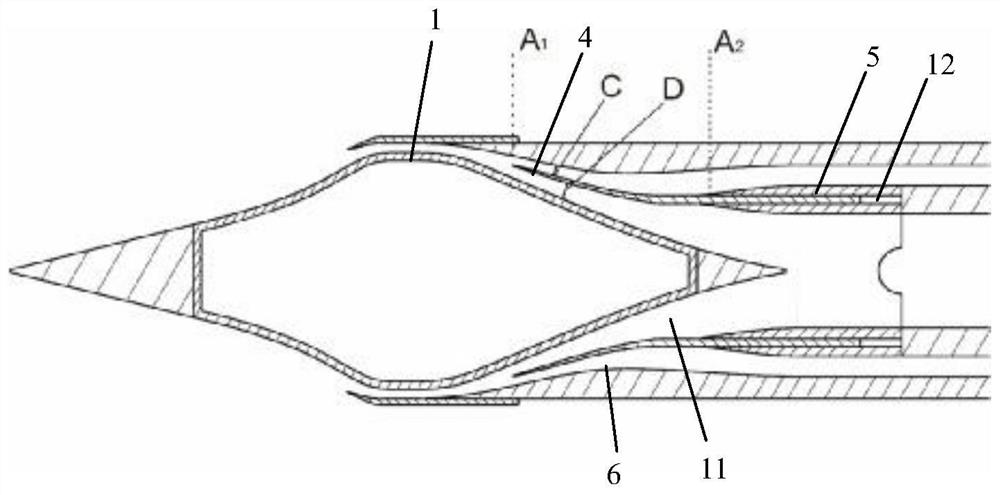

[0026] see figure 1 As shown, the present invention provides an axisymmetric inner-parallel turbine-based rotary detonation ramjet combination engine, which includes a rotary detonation ramjet engine 9, a turbine engine 8 located in the rotary detonation ramjet engine, and an annular ring located at the front end of the turbine engine 8 The ring wall 5 of the rotary detonation ram runner, and the central body 1 located in front of the inner ring wall 5 of the rotary detonation ram runner. The rotary detonation ramjet has an annular engine outer wall 7 . The space formed between the turbine engine 8 and the engine outer wall 7 is a rotating detonation ram runner 6 extending from front to back. The center of the turbine engine 8 is provided with a turbine channel 11 extending from the front to the rear. The front of the engine outer wall 7 is an intake lip cover 3 that can move back and forth around the central body. The air intake lip cover 3 and the central body 1 form an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com