Device for detecting viscosity and density of suspensoid media by drop manner

A suspension and viscosity technology, which is used in the determination of specific gravity by measuring pressure difference and the measurement of DC flow characteristics. performance and reliability, eliminating influence, overcoming the effect of large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

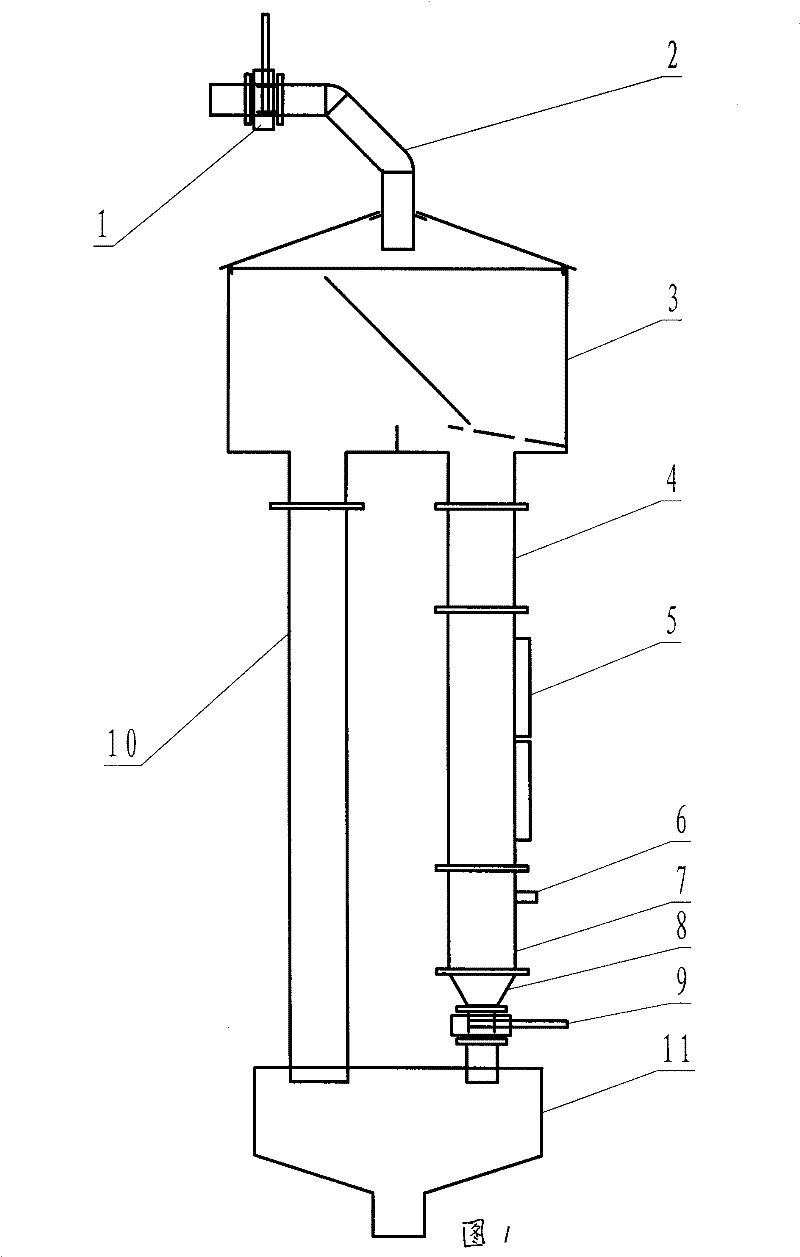

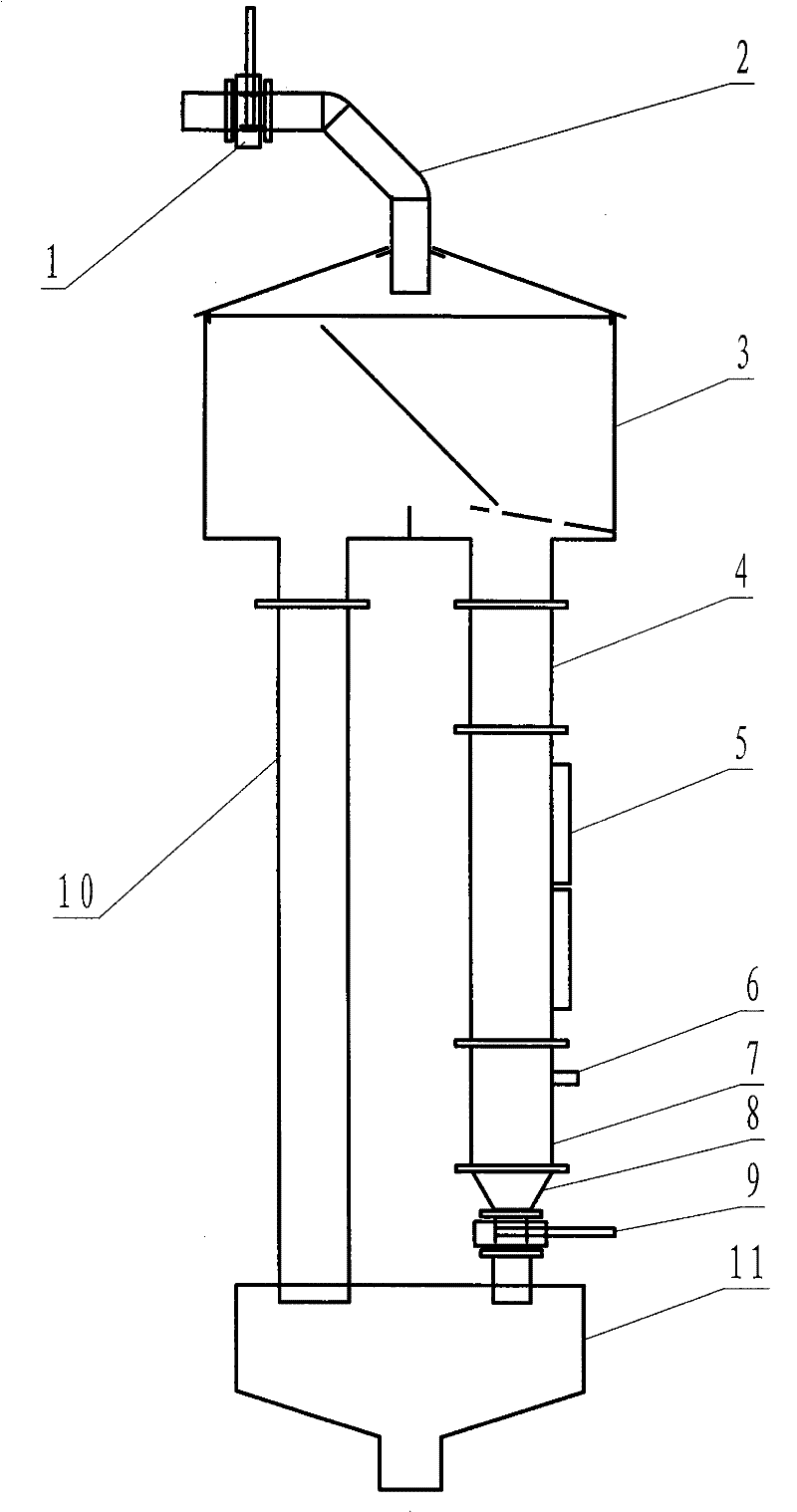

[0014] see figure 1 , the present invention is composed of feeding automatic switching valve 1, feeding pipe 2, constant pressure shunt box 3, detection pipe 4, overflow pipe 10, differential pressure diaphragm and secondary instrument 5, discharging automatic switching valve 9, collection box 11 compositions.

[0015] The inlet of feeding pipe 2 is connected to the input pipe of dense medium suspension, and the outlet is connected to the input port of constant pressure shunt box 3. The automatic feeding switch valve 1 is installed on the feeding pipe 2, and the detection pipe 4 and overflow valve are installed under the constant pressure shunt box 3. Flow pipe 10, detection pipe 4 and overflow pipe 10 are placed vertically side by side, and their lower ends pass into collection box 11, and the discharge automatic switch valve 9 is installed in the junction of detection pipe 4 and collection box 11, the bottom of collection box 11 and The dense medium suspension output pipes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com