Absorbability article, belt structure, method for manufacturing belt structure and absorbability article

A manufacturing method and absorbent technology, which can be used in absorbent pads, bandages, medical science, etc., can solve problems such as difficulty in the connection process, and achieve the effects of less entanglement, greater flexibility, and space saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Preferred embodiments of the disclosure of the present application are described below with reference to the accompanying drawings. Similar or identical elements are given the same reference numerals, and description of these features is not repeated in each embodiment.

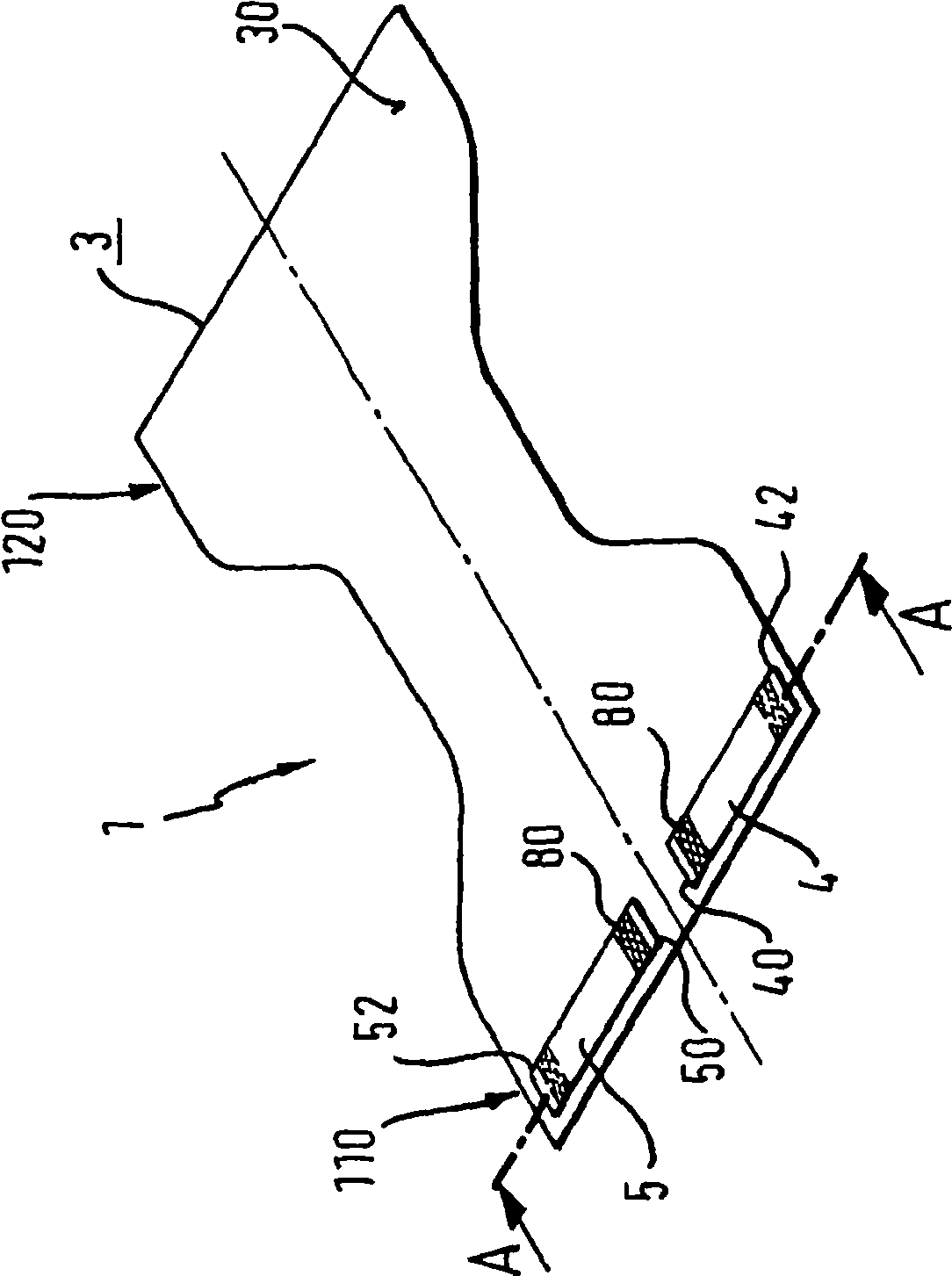

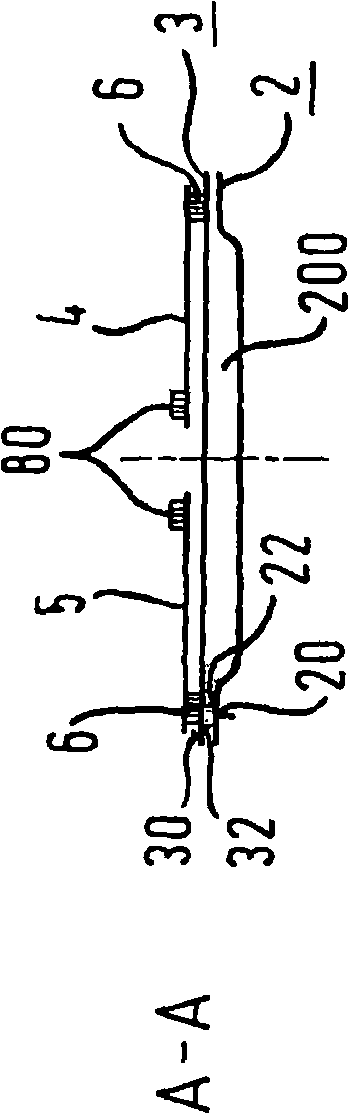

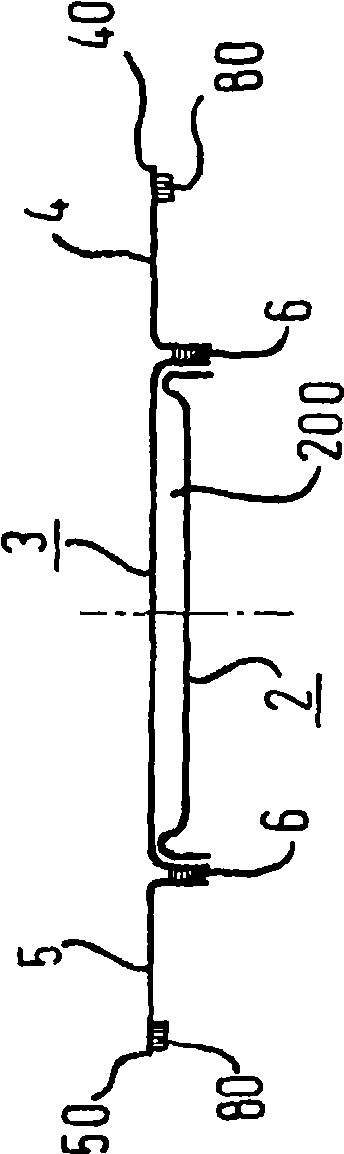

[0065] Figures 1a to 1d show a first embodiment of an absorbent article 1 in schematic perspective views. The absorbent article 1 has a back sheet 3, the outer side 30 of which is visible in Figure 1a. The first elongated strip 4 and the second elongated strip 5 are shown attached to the outer side 30 of the back sheet 3 .

[0066] As can also be seen in FIG. 1 a , the back sheet 3 is oriented with its inner side 32 facing the inner side 22 of the top sheet 2 . The outer side 20 of the top sheet 2 is not directly connected to the first elongated strip 4 or the second elongated strip 5 .

[0067] Between the top sheet 2 and the back sheet 3 there is arranged an absorbent core 200 for absorbing liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com