Vortex compressor

A scroll compressor and casing technology, applied in the field of compressors, can solve the problem of high cost, and achieve the effects of reducing manufacturing costs, preventing damage, and reducing processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

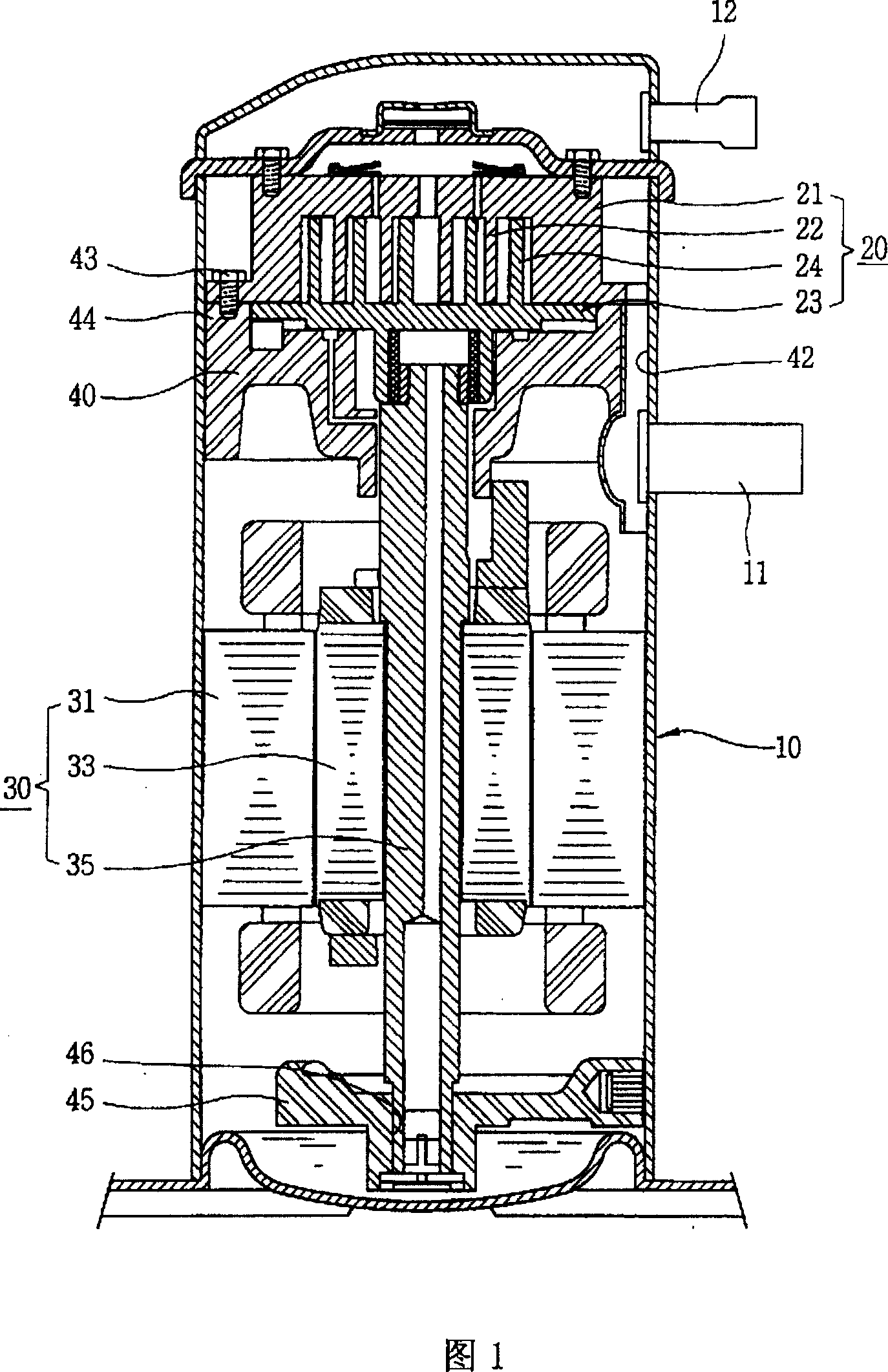

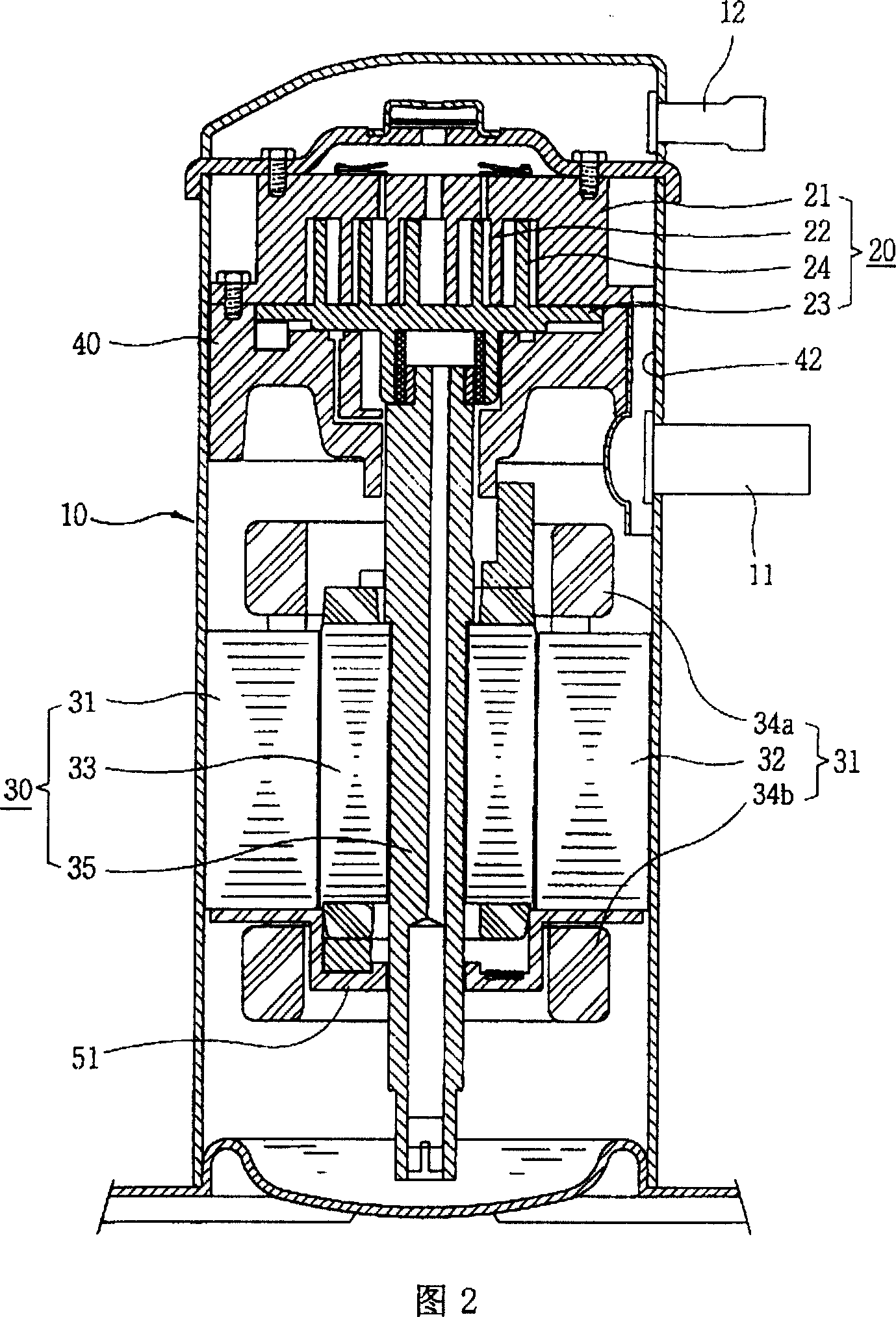

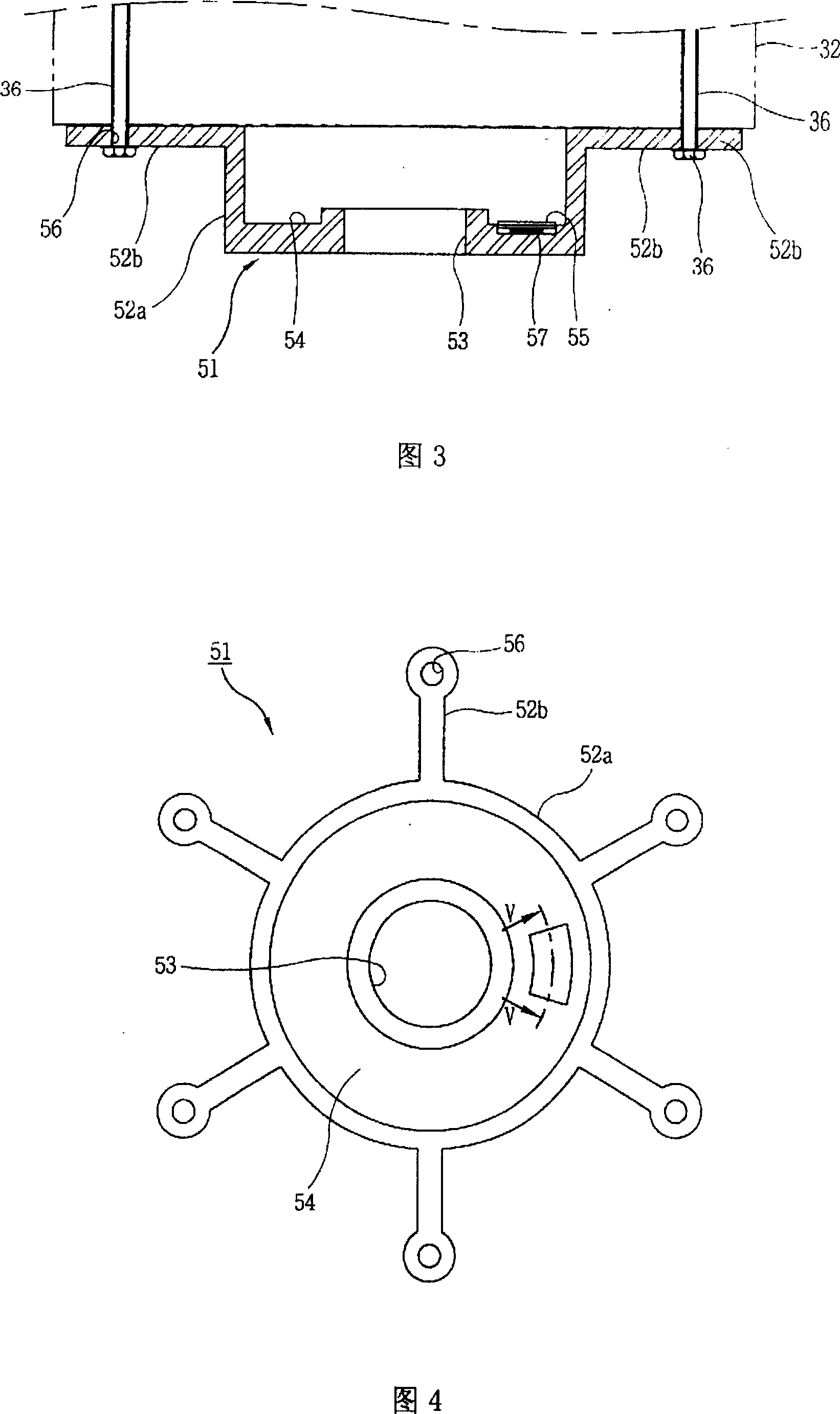

[0037] Below in conjunction with accompanying drawing and specific embodiment, the present invention is described in further detail: Fig. 2 shows the longitudinal sectional view of the scroll compressor of the embodiment of the present invention, Fig. 3 shows the enlarged sectional view of lower support in Fig. 2, Fig. 4 An enlarged top view of the lower bracket in FIG. 3 is shown, and FIG. 5 shows an enlarged cross-sectional view of the V-V section in FIG. 4 .

[0038] As shown in the above drawings, the scroll compressor has the following structure: the inside of the casing 10 is a closed space; the compression unit 20 is installed above the inside of the casing 10 to compress the refrigerant sucked from the outside; the motor 30 is installed in the compressor Below the part 20, the motor shaft is the rotating shaft 35, which provides driving force to the compression part 20 through the rotating shaft 35; the upper frame 40 is arranged above the inside of the casing 10, suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com