Automatic transmission controlling apparatus and method

A technology of automatic transmission and control device, applied in the direction of transmission control, components with teeth, belt/chain/gear, etc., which can solve the problems of speed change shock, lengthening of speed change action period, and inability to detect rotational speed of rotating elements, etc. Achieve the effect of suppressing shifting shock and improving responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

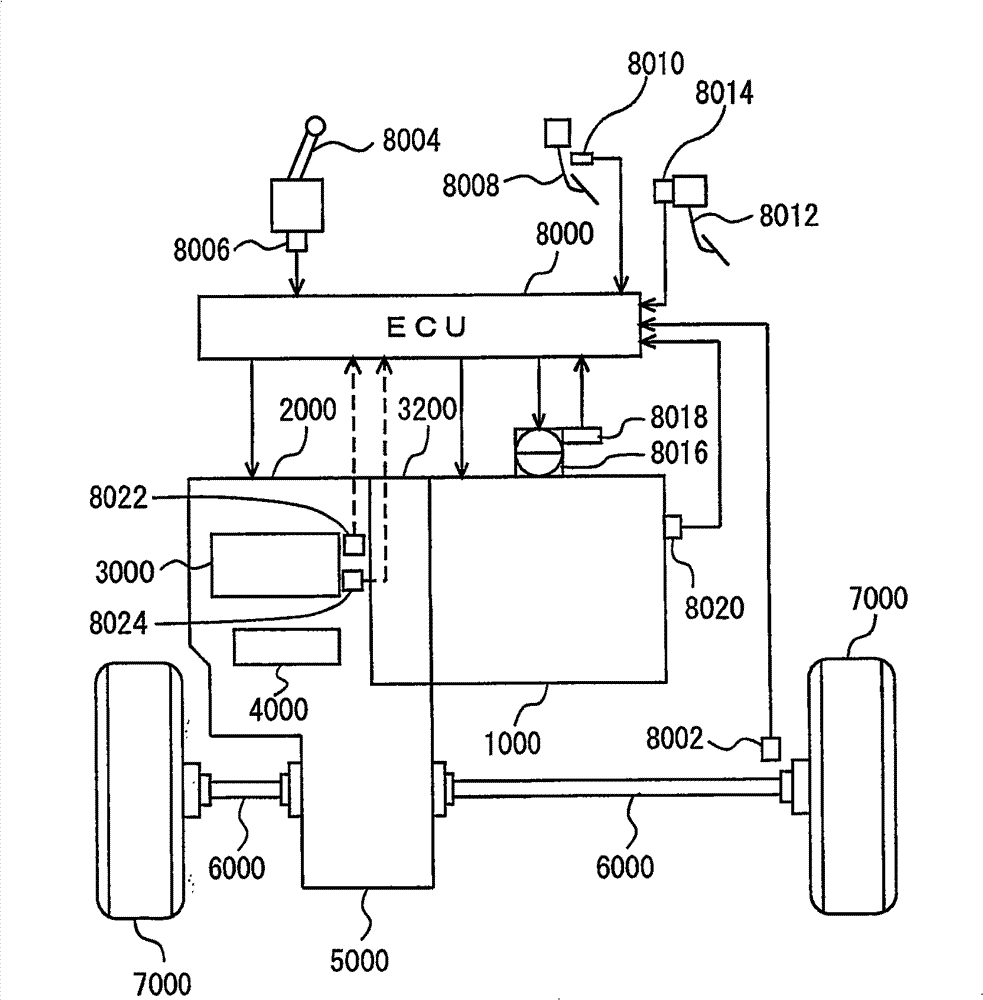

[0045] refer to figure 1 A vehicle equipped with a control device according to an embodiment of the present invention will be described. This vehicle is an FF (Front engine Front drive) vehicle. Vehicles other than FF may also be used.

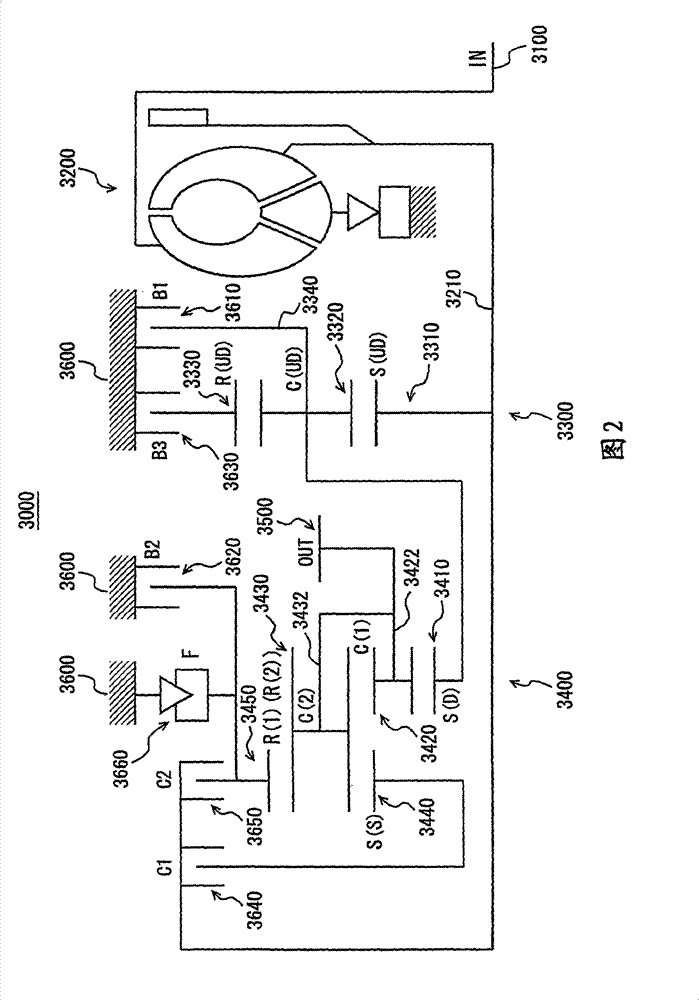

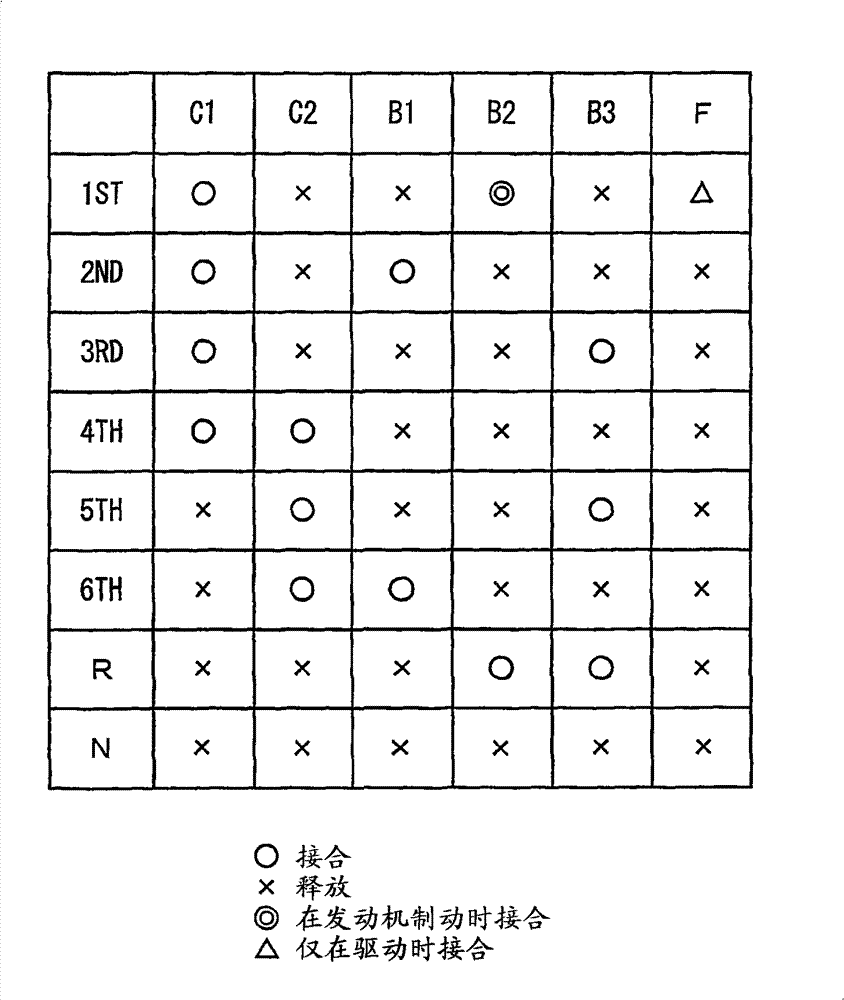

[0046] The vehicle includes an engine 1000, an automatic transmission 2000, a planetary gear unit 3000 constituting a part of the automatic transmission 2000, a hydraulic circuit 4000 constituting a part of the automatic transmission 2000, a differential gear 5000, a drive shaft 6000, front wheels 7000, an ECU (Electronic Control Unit )8000. The control device of the automatic transmission of the present invention is realized by ECU8000.

[0047] Engine 1000 is an internal combustion engine that combusts a mixture of fuel and air injected from an injector (not shown) in a combustion chamber of a cylinder. Combustion depresses the piston in the cylinder and rotates the crankshaft.

[0048] Automatic transmission 2000 is connected to engine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com