Apparatus for measuring the volume or mass flow of a medium in a pipeline

A technology for measuring pipelines and volume flow, applied in the direction of measuring flow/mass flow, volume/mass flow generated by electromagnetic effects, measuring devices, etc., can solve the problems of relatively expensive and high manufacturing costs of magnetic induction flowmeters, and achieve high corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

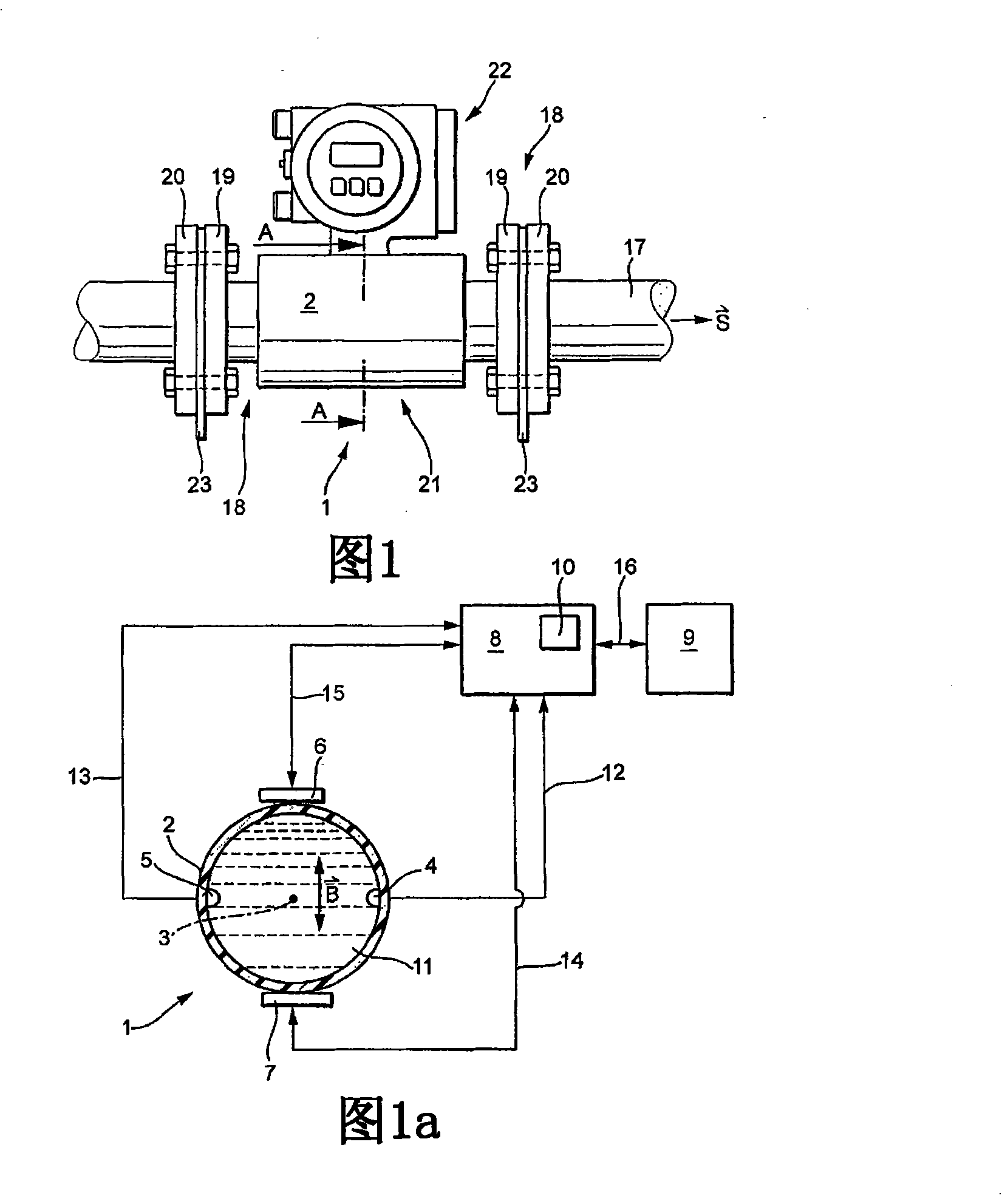

[0019] figure 1 is a plan view of one embodiment of the device 1 of the present invention. The flow meter 1 installed in the pipe 17 is composed of a sensor 21 and a transmitter 22 . Sensitive electronic components such as the control / evaluation unit 8 are arranged in the transmitter 22 .

[0020] A measuring tube flange 19 is fastened in each of the two end regions 18 of the measuring tube 2 of the flow meter 1 . Either the measuring tube flange 19 is welded to the measuring tube 2 ; or the measuring tube flange 19 is a loose flange which is pushed onto the measuring tube 2 with play and passes through the measuring tube 2 in the installed state of the flowmeter 1 The crimped end region 18 is fixed axially on the measuring tube 2 .

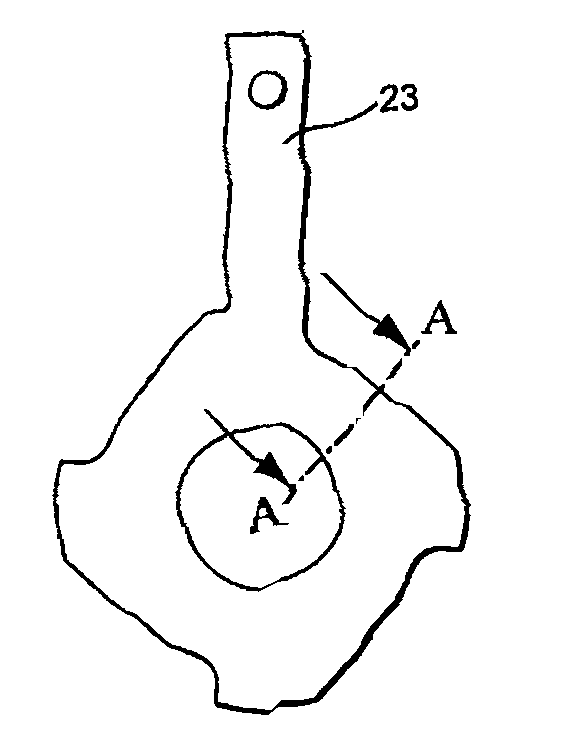

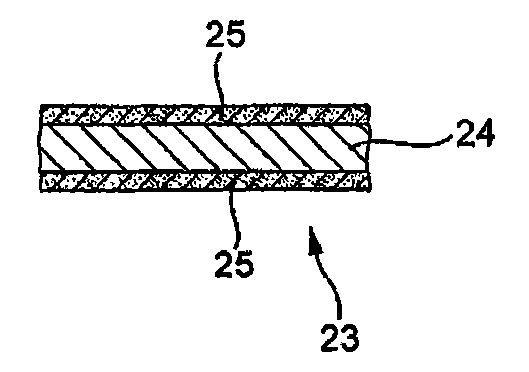

[0021] Two pipe flanges 20 are mounted on the two end regions of the pipe 17 between which the flow meter 1 is located. Between the measuring tube flange 19 and the pipe flange 20 an inventive ground disc 23 is provided. In addition to the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com