Automatic flow rate adjusting device

An automatic adjustment and flow rate technology, applied to valve devices, engine components, safety valves, etc., can solve problems such as difficult voltage regulation and insufficient sensitivity, and achieve the effects of avoiding mechanical friction, high detection sensitivity, and sensitive voltage regulation adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the following, the present invention will be described and illustrated in more detail in the form of specific embodiments according to the accompanying drawings.

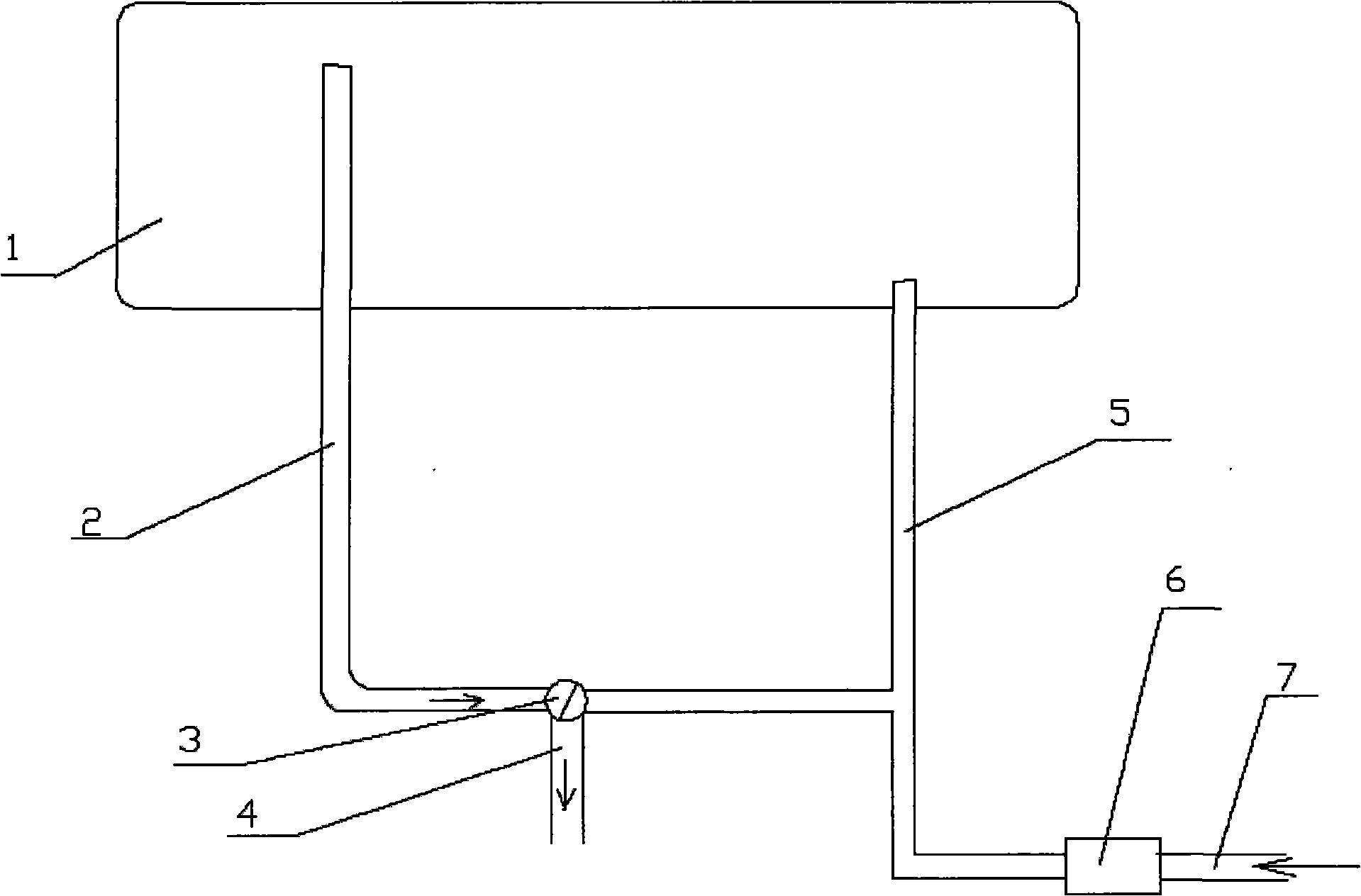

[0030] figure 1 It shows that the flow automatic regulating device according to the present invention is connected in the water inlet pipeline of the cold water pipe when used in a water heater. The water heater generally comprises a water tank 1, a hot water outlet pipe 2, a three-way mixing valve 3, an outlet pipe 4 of the three-way mixing valve 3, and a cold water inlet pipe 5 of the water heater. The flow automatic regulating device 6 of the present invention is connected between the cold water inlet pipe 7 (that is, the tap water pipe) and the cold water inlet pipe 5 of the water heater.

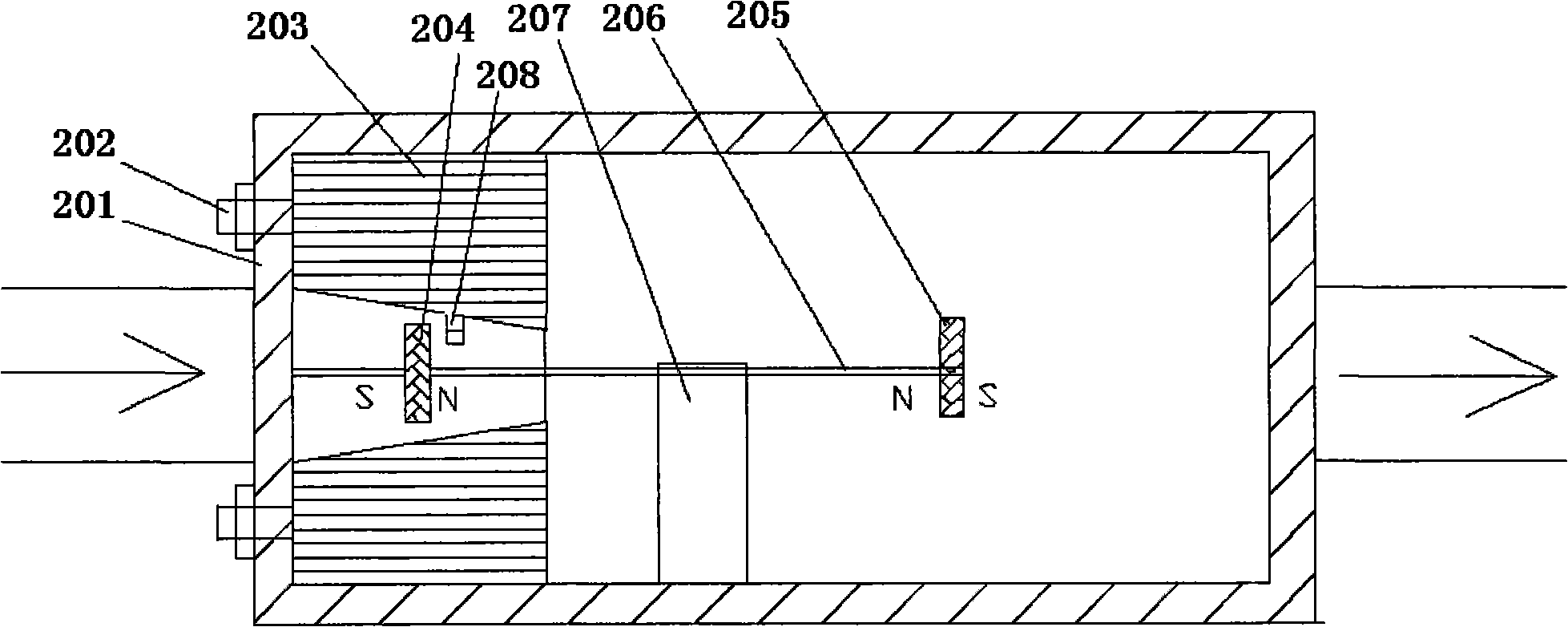

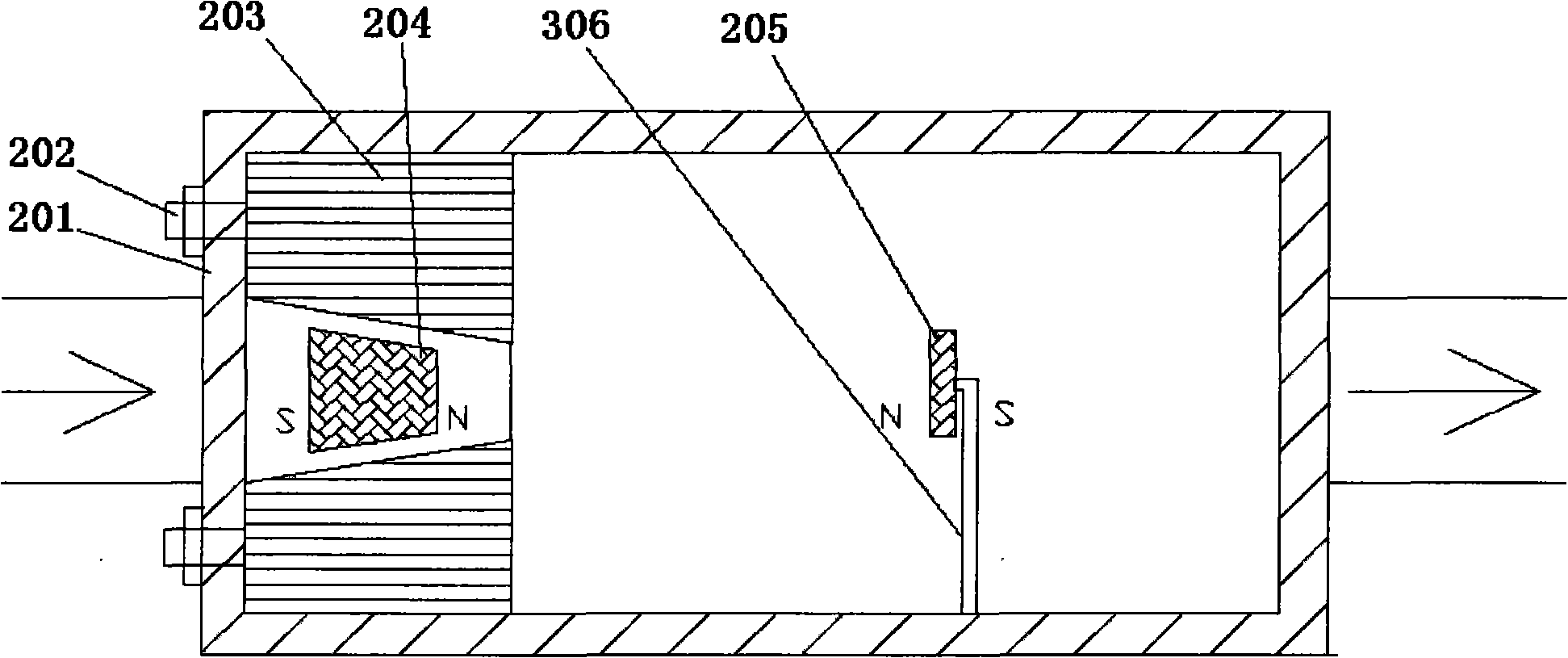

[0031] see below figure 2 The first embodiment shown is a detailed description of the automatic flow adjustment device of the present invention, and the automatic flow adjustment device includes:

[0032] The ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com