High voltage automobile power cell

An automotive power battery and high-voltage technology, applied in lead-acid batteries, battery pack components, lead-acid battery construction, etc., can solve problems such as large current charge-discharge voltage drop, restricting the application of high-voltage batteries, and easy corrosion and deformation of grids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

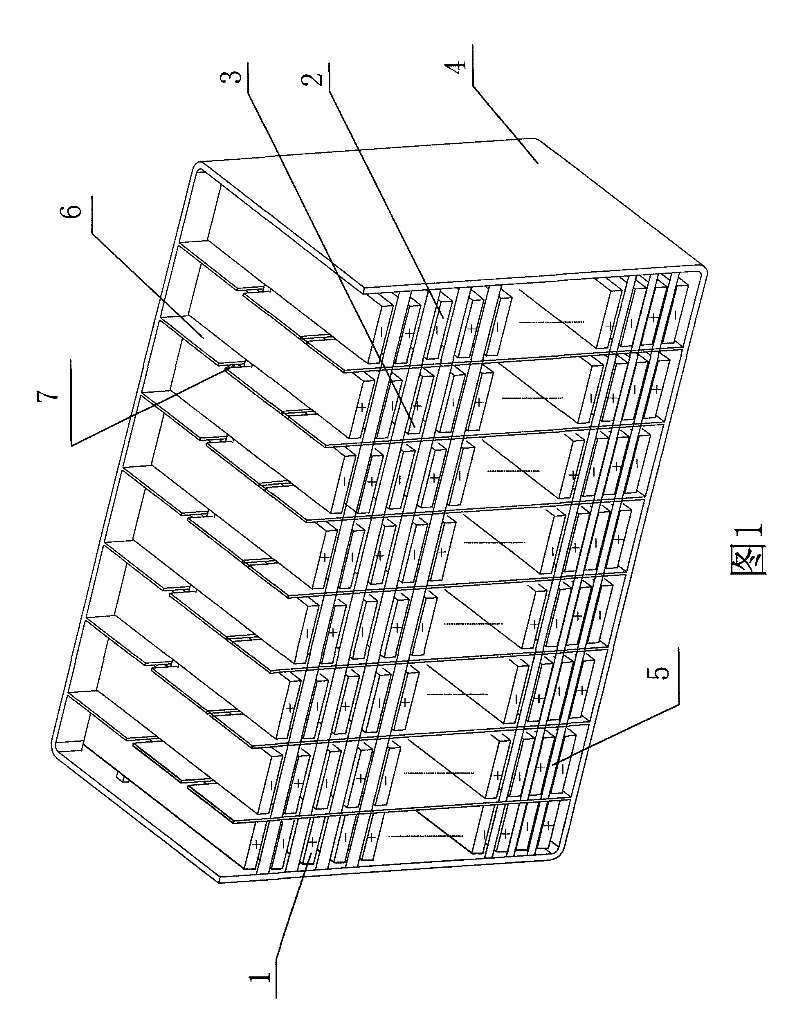

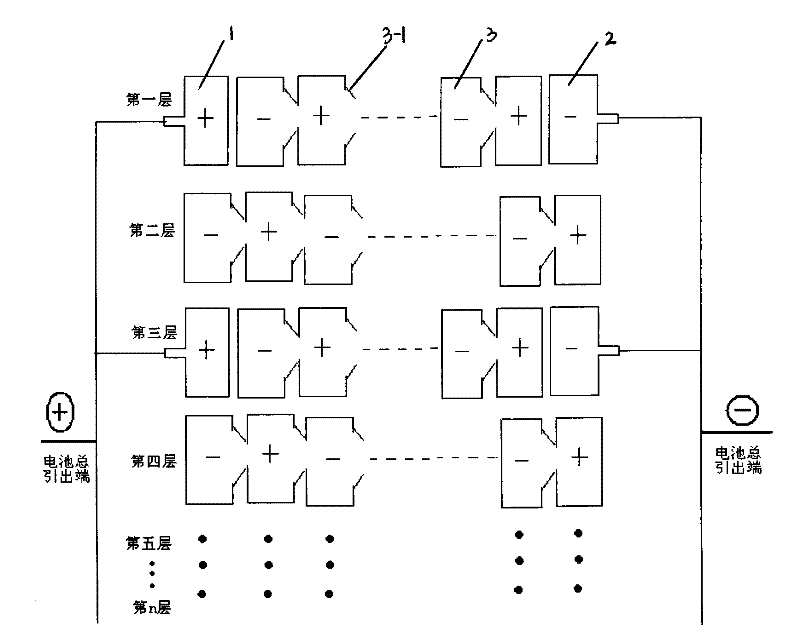

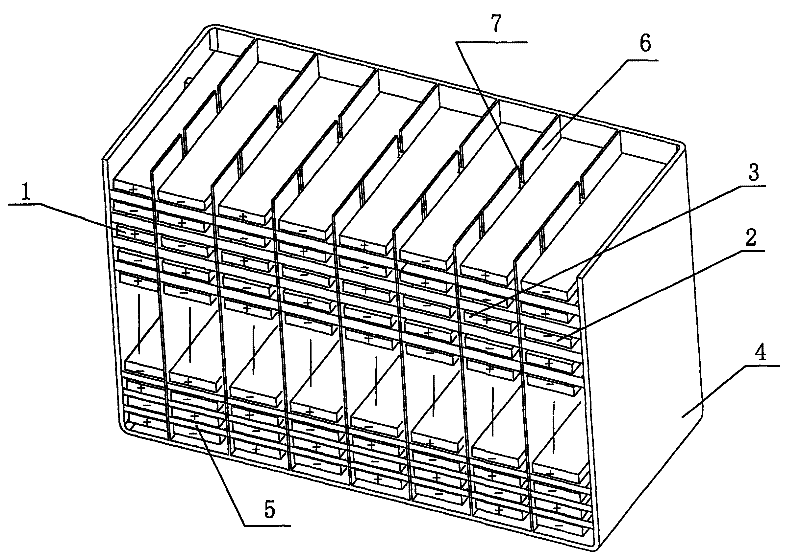

[0008] As shown in Figures 1 and 2, the present invention is made up of housing 4 and three kinds of pole plates, one of which is a positive end pole plate 1, the other is a negative end pole plate 2, and the third is an even number of positive and negative alternating phases, and A continuous pole plate 3 formed by connecting successively through twisted wires 3-1.

[0009] The positive and negative plates are separated in the vertical direction by the porous separator 5 in the casing 4 to form an even number of layers.

[0010] Positive end plates 1 and negative end plates 2 are respectively arranged at both ends of each odd layer, and continuous plates 3 are arranged in the middle, and the plates at both ends of the continuous plate 3 in each odd layer are connected to the corresponding layers The poles of the positive end plate 1 and the negative end plate 2 at the two ends of the structure are opposite to each other, the positive end plate 1, the negative end plate 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com