Solar cell inverter of MgZnO film transistor having circular structure and preparation method thereof

A technology of thin-film transistors and solar cells, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of high cost of photovoltaic cell power inverters, low attractiveness of BIPV applications, and affecting the wide application of BIPV. Achieve the effects of easy popularization and application, convenient control and operation, high temperature and electrical performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

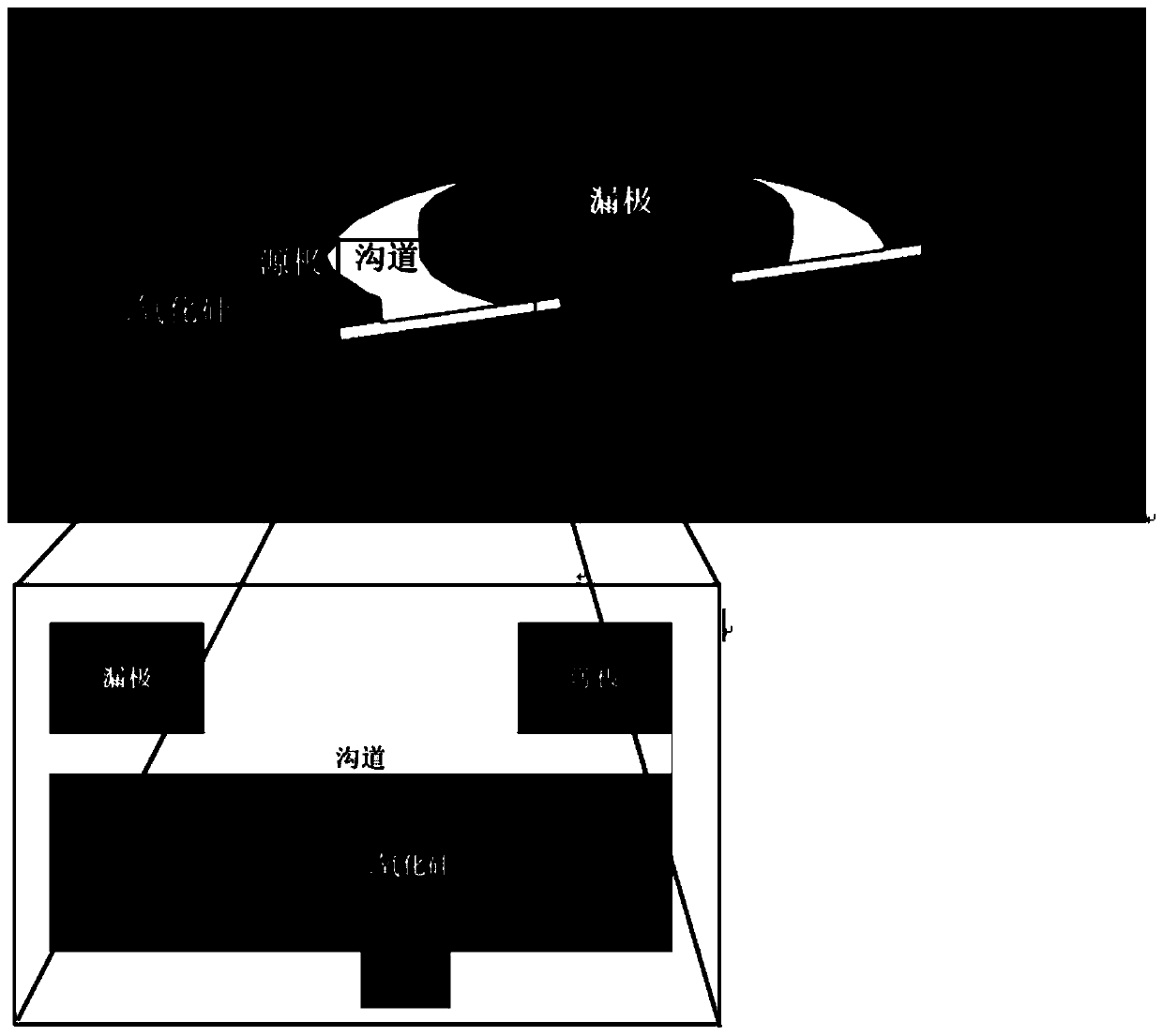

[0032] In this example, see figure 1 , a solar cell inverter with a circular MgZnO thin film transistor, its structure adopts the structural combination form of substrate-electrode-insulating layer-channel-electrode, which is sequentially composed of glass substrate-Cr electrode, SiO 2 The insulating layer, the MZO channel and the Au electrode are stacked and assembled to form a transparent thin film transistor. The substrate is made of transparent glass, and the MZO film is a transparent film. The solar cell inverter structure of the circular structure MgZnO thin film transistor adopts the structural combination of substrate-electrode-insulating layer-channel-source electrode and drain electrode, and combines ring-shaped metal gate electrode and channel layer on the glass substrate MZO film is used to form a ring-shaped film with a width of 15 μm on the corresponding position of the ring-shaped gate electrode, making it a ring-shaped channel of the thin film transistor. The r...

Embodiment 2

[0055] This embodiment is basically the same as Embodiment 1, especially in that:

[0056] In this embodiment, a solar cell inverter with circular structure MgZnO thin film transistor adopts the structural combination form of substrate-electrode-insulating layer-channel-electrode, which consists of glass substrate-Cr electrode, SiO 2 The insulating layer, the MZO channel and the Au electrode are stacked and assembled to form a transparent thin film transistor. The substrate is made of transparent glass, and the MZO film is a transparent film. The solar cell inverter structure of the circular structure MgZnO thin film transistor adopts the structural combination of substrate-electrode-insulating layer-channel-source electrode and drain electrode, and combines ring-shaped metal gate electrode and channel layer on the glass substrate MZO film is used to form a ring-shaped film with a width of 35 μm on the corresponding position of the ring-shaped gate electrode, making it a ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com