Ecr plasma source

A plasma source, plasma technology, applied in circuits, discharge tubes, electrical components, etc., can solve problems such as hindering electric power coupling, short circuit, limiting coating time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

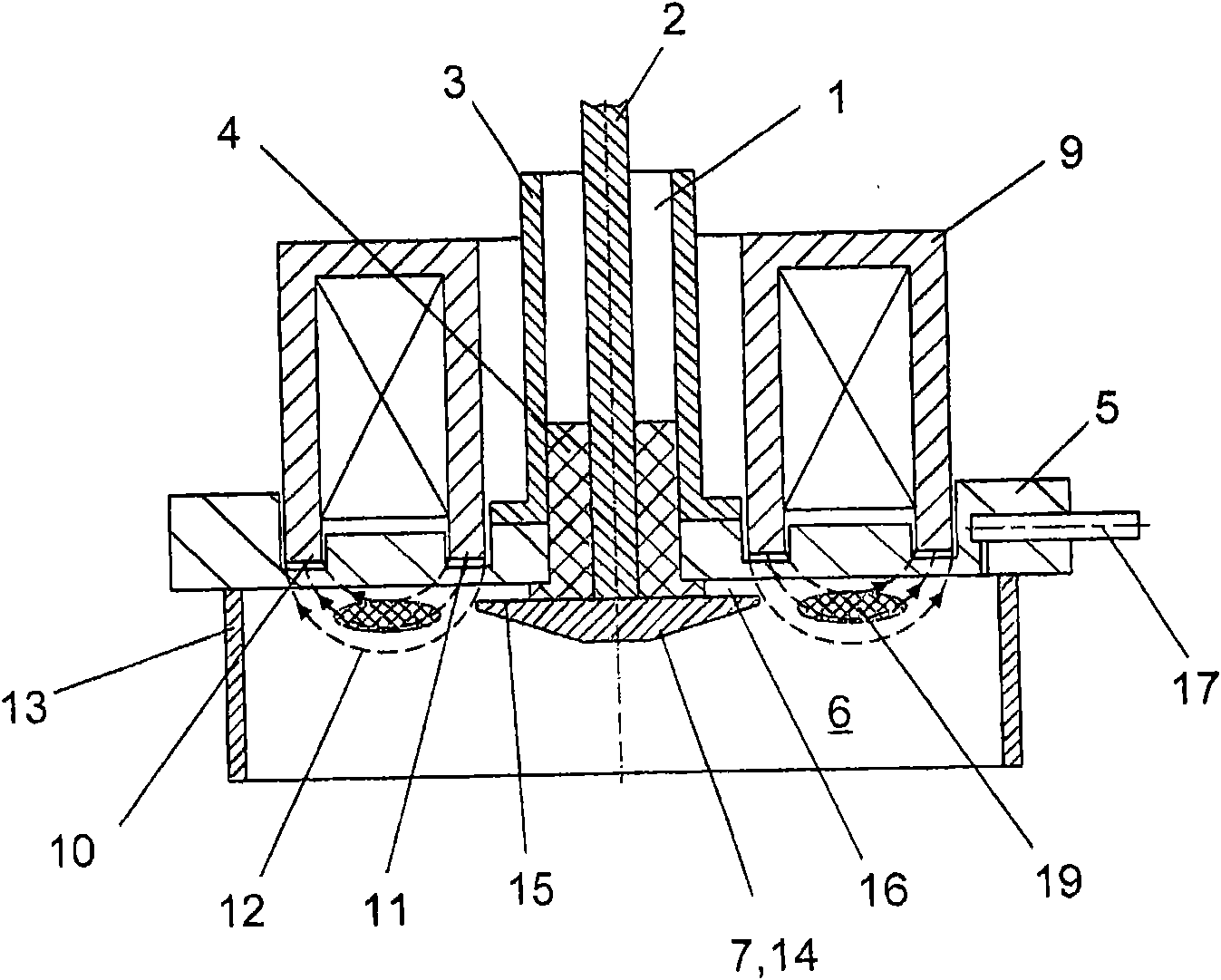

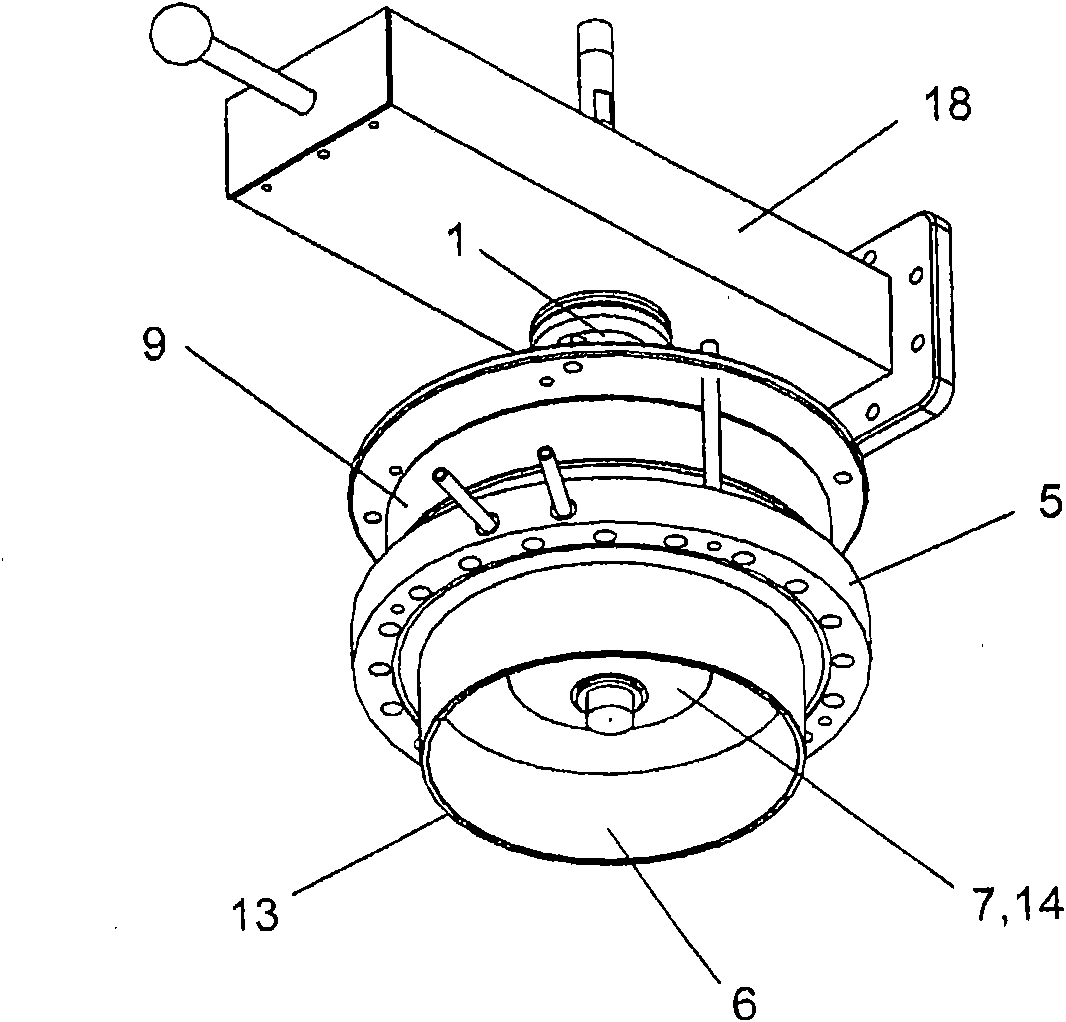

[0021] figure 1 It shows the principle structure of an ECR plasma source proposed by the present invention. The ECR plasma source comprises a coaxial microwave supply line 1 provided with an inner conductor 2 and an outer conductor 3 coaxial with the inner conductor 2 . The inner conductor 2 is insulated from the outer conductor 3 by a dielectric 4 . In this case, the dielectric body 4 simultaneously ensures that the inner conductor 2 is passed through a vacuum flange 5 in an insulated manner, so that the respective ends of the inner conductor 2 protrude freely into the plasma chamber.

[0022] The vacuum flange 5 is designed as a mounting flange, which closes an opening in the wall to the plasma chamber 6 in a vacuum-tight manner.

[0023] The end of the inner conductor 2 , which forms the antenna 7 of the microwave supply line 1 , extends through the vacuum flange 5 and into the plasma chamber 6 . Coaxial to the microwave supply line 1 , outside the plasma chamber 6 there...

Embodiment II

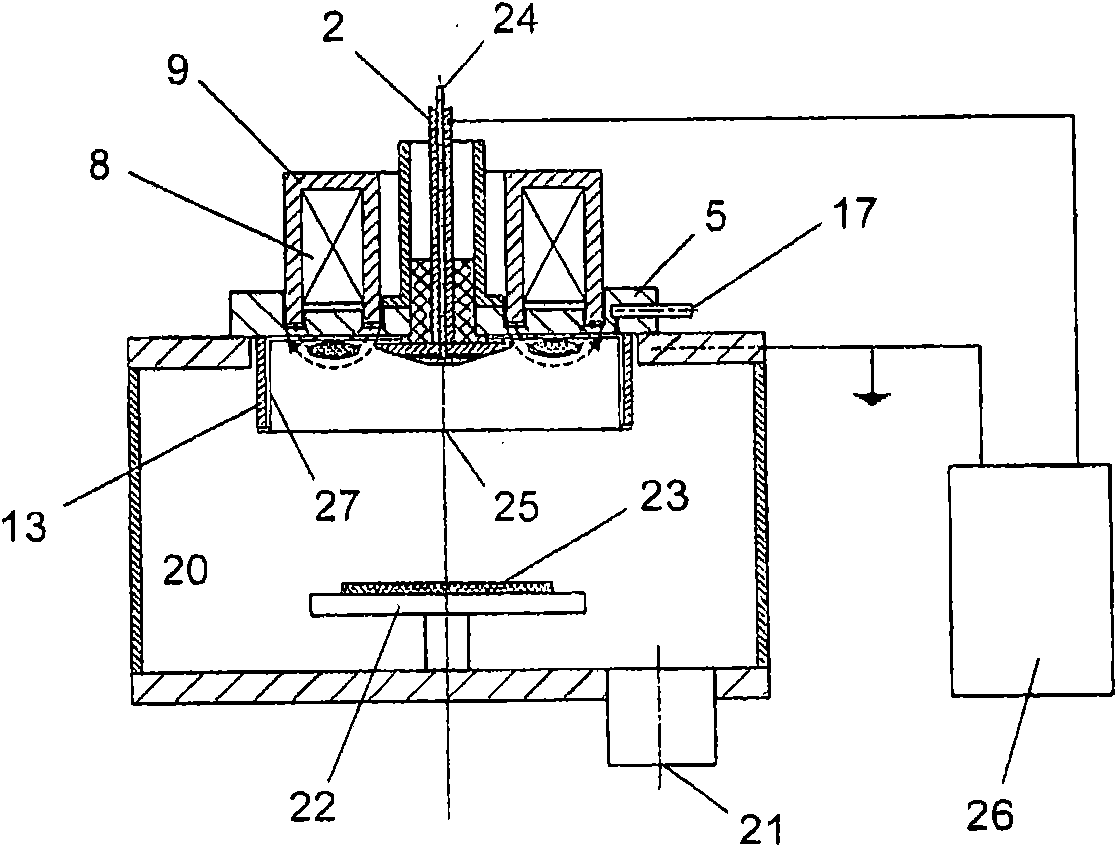

[0029] Belonging to Example II image 3 show a figure 1 The shown ECR plasma source is similar in form of construction, but in a schematic overview there is a coating device which mainly comprises a vacuum chamber 20 equipped with an extraction nozzle 21 and a substrate holder 22, to be processed The substrate 23 can be placed on the support.

[0030] The ECR plasma source proposed according to the invention has a plasma outlet 25 corresponding to the end face of the shield 13 facing away from the vacuum flange 5 , which is arranged parallel to the substrate support 22 .

[0031] In addition to the hole 17 corresponding to Example I, there is also a hole 24 concentrically on the inner conductor 2 . Via these two holes 17 and 24 , carrier and reaction gases can be selectively fed into the vacuum chamber 20 .

[0032] As in embodiment I, the inner conductor 2 and the antenna 7 are insulated in the outer conductor 3 of the microwave supply line 1 . This makes it possible to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com