Polygon mirror scanner motor and method of manufacturing the same

A manufacturing method, technology of polygonal mirrors, applied in the direction of instruments, mirrors, physical instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment approach 1

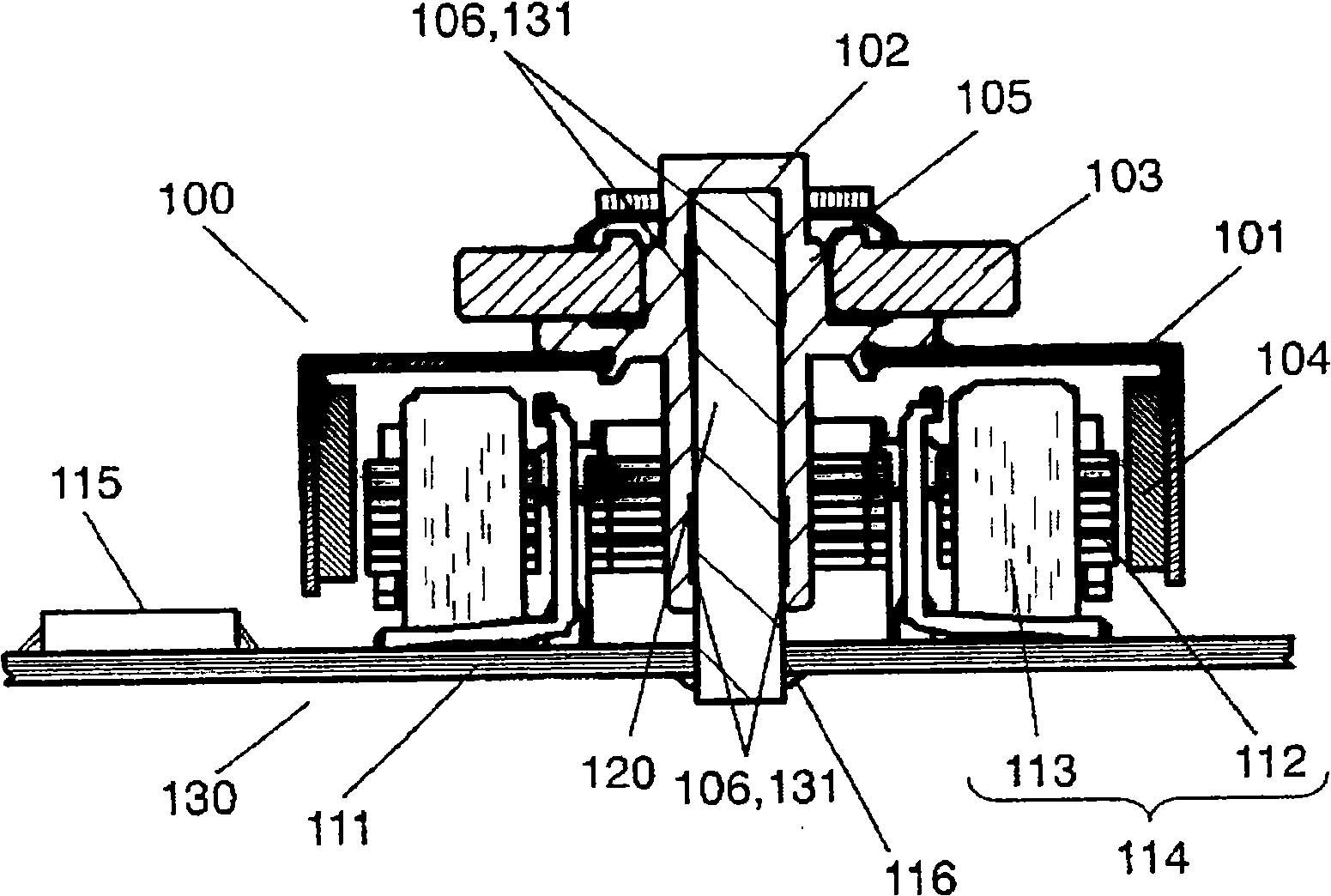

[0087] figure 1 It is a sectional view of the polygon mirror scanner motor according to Embodiment 1 of the present invention. First, refer to figure 1 The main configuration of the polygon mirror scanner motor according to Embodiment 1 of the present invention will be described.

[0088] The polygon mirror scanner motor according to Embodiment 1 includes: a rotor 100 , a winding assembly 114 , a stator 130 , a rotating shaft 120 , and a dynamic pressure bearing 131 . The rotor 100 consists of a rotor frame 101, a rotor magnet 104 attached to the inner wall of the rotor frame 101, a rotor boss 102 having a cylindrical portion 105 and attached to the rotor frame 101, and a polygon mirror (rotary polygon mirror) attached to the rotor boss 102. 103 composition. The winding assembly 114 is composed of a stator core 112 on which magnetic materials are laminated and arranged to face the rotor magnet 104 , and a stator coil 113 wound on the stator core 112 . The stator 130 is c...

Embodiment approach 2

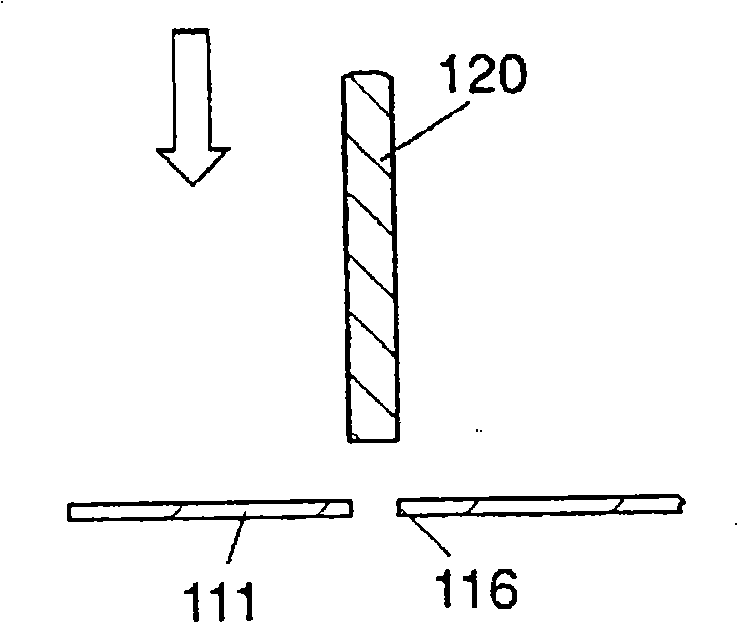

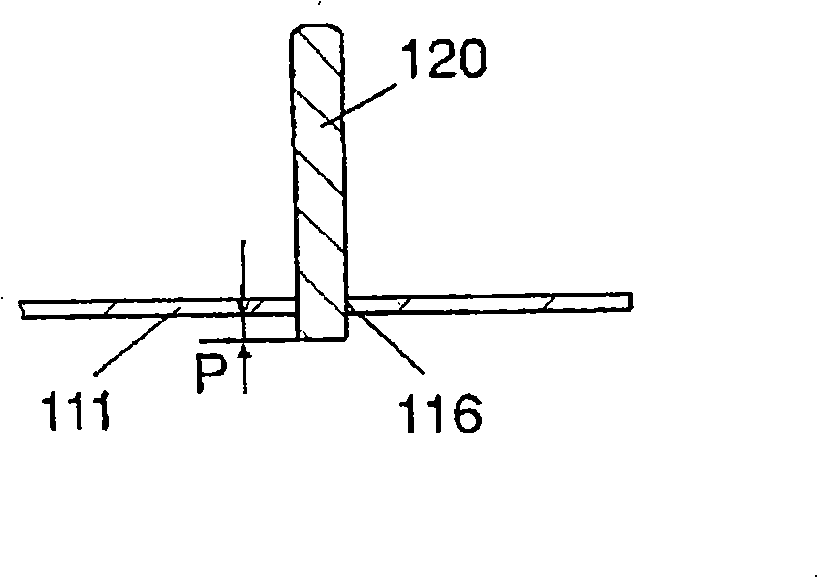

[0109] refer to image 3 A method of manufacturing the polygon mirror scanner motor according to Embodiment 2 of the present invention will be described. image 3 is a cross-sectional view of a jig used in the method of manufacturing a polygon mirror scanner motor according to Embodiment 2 of the present invention.

[0110] The jig 200 includes a fastener 202 for pressing the iron circuit board 111 against the pressing surface 220 of the jig, and a bracket 203 for holding the rotating shaft 120 at right angles to the pressing surface 220 of the jig. The bracket 203 sandwiches and holds the rotating shaft 120 from both sides parallel to the pressing surface 220 of the jig. Furthermore, the jig 200 further includes an opening and closing mechanism (not shown) for opening and closing the bracket, and a moving mechanism (not shown) for moving the fastener 202 up and down in the axial direction.

[0111] The manufacturing method of the polygon mirror scanner motor according to Em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com