Gripper bar with swinging device and operating method thereof

A technology of a swinging device and a working method, which is applied in the field of tooth rows, can solve the problems of increased manufacturing cost and maintenance cost, difficult operation by workers, many connecting parts, etc., and achieves the advantages of shortened downtime frequency and downtime, comfortable operation and strong flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

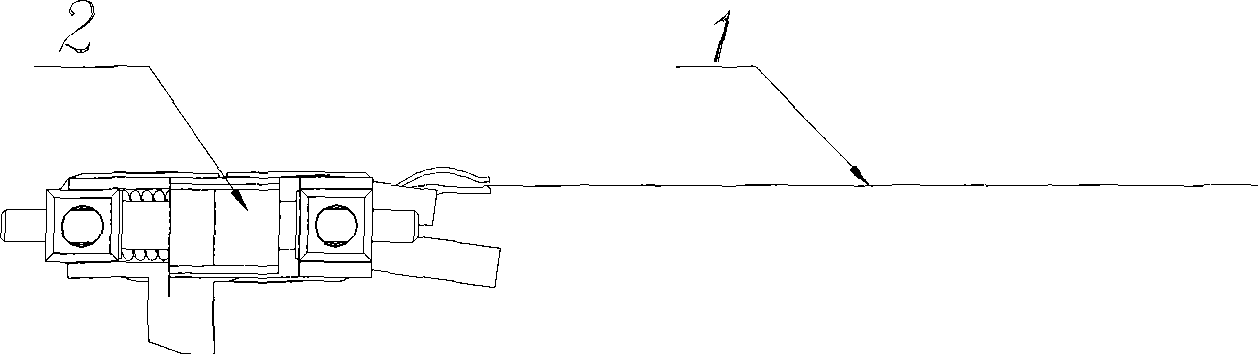

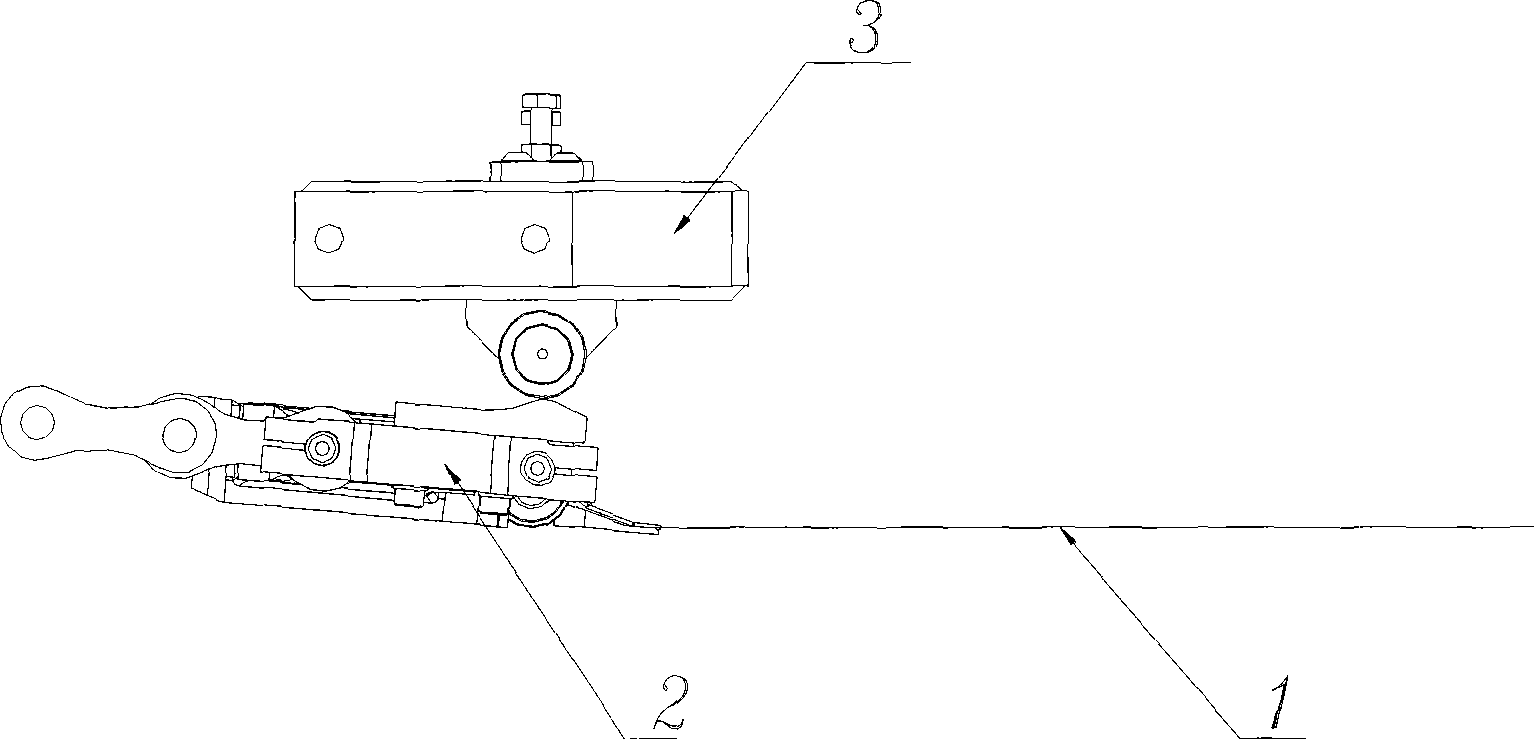

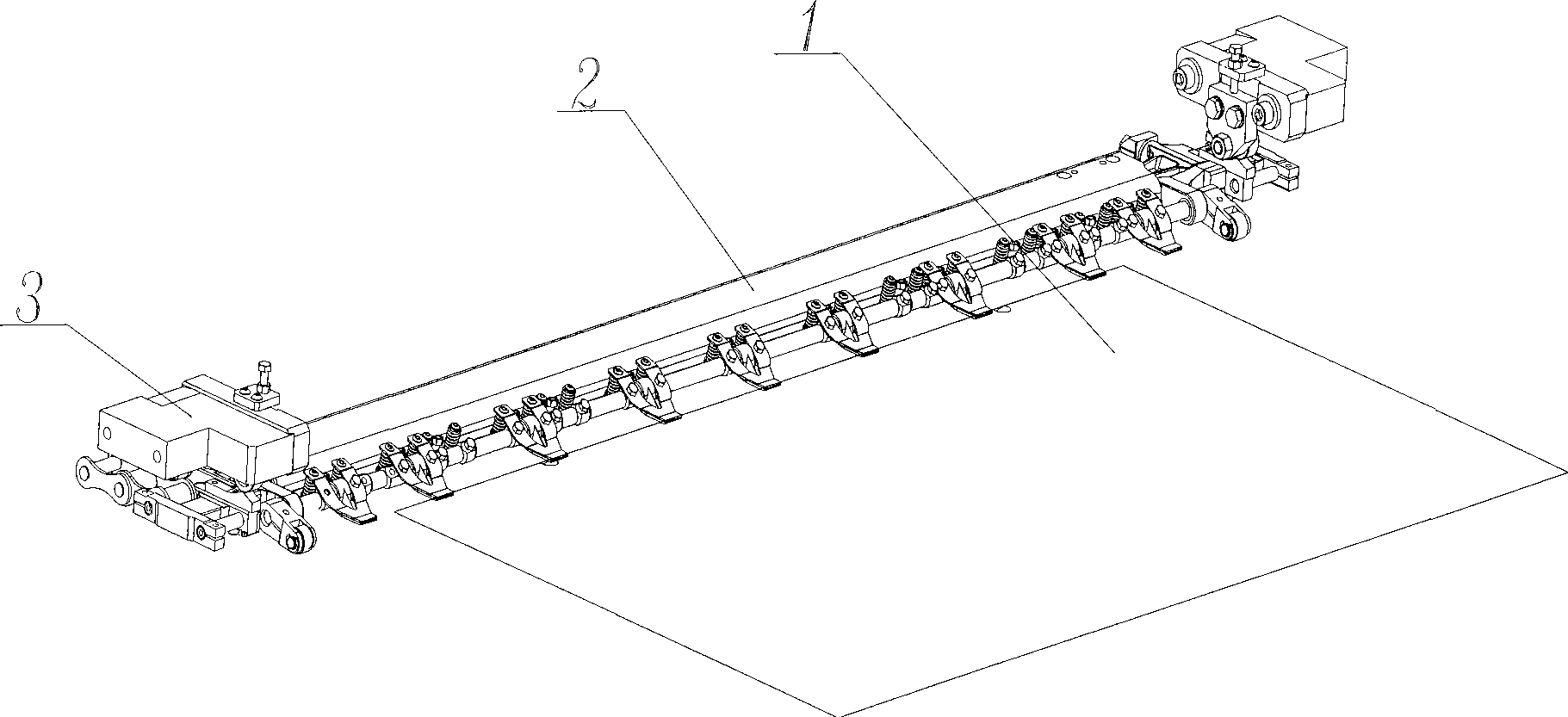

[0024] Embodiment: a kind of row of teeth that swing device is arranged (see figure 2 , image 3 ), including tooth row 2, is characterized in that it also includes cam follower mechanism 3 and cam block 3-5; Wherein cam follower mechanism 3 is installed on the wallboard of working position; Said cam block is installed on the tooth row 2, and corresponding to the cam follower 3, the highest position of the cam block 3-5 is consistent with the center of the cam follower 3.

[0025] The above-mentioned cam follower mechanism 3 is symmetrically installed on both side wallboards of the working position. (See image 3 )

[0026] The above-mentioned cam blocks 3-5 are symmetrically installed on both sides of the tooth row 2 . (See image 3 )

[0027] The above-mentioned cam follower mechanism 3 (see Figure 4 ) includes a support block 3-1, an adjustment fixed plate 3-2, an adjustment block 3-3, a fixed seat 3-4 and a cam follower bearing 3-6; wherein the support block 3-1 i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap