Method for controlling strip-steel head and tail temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

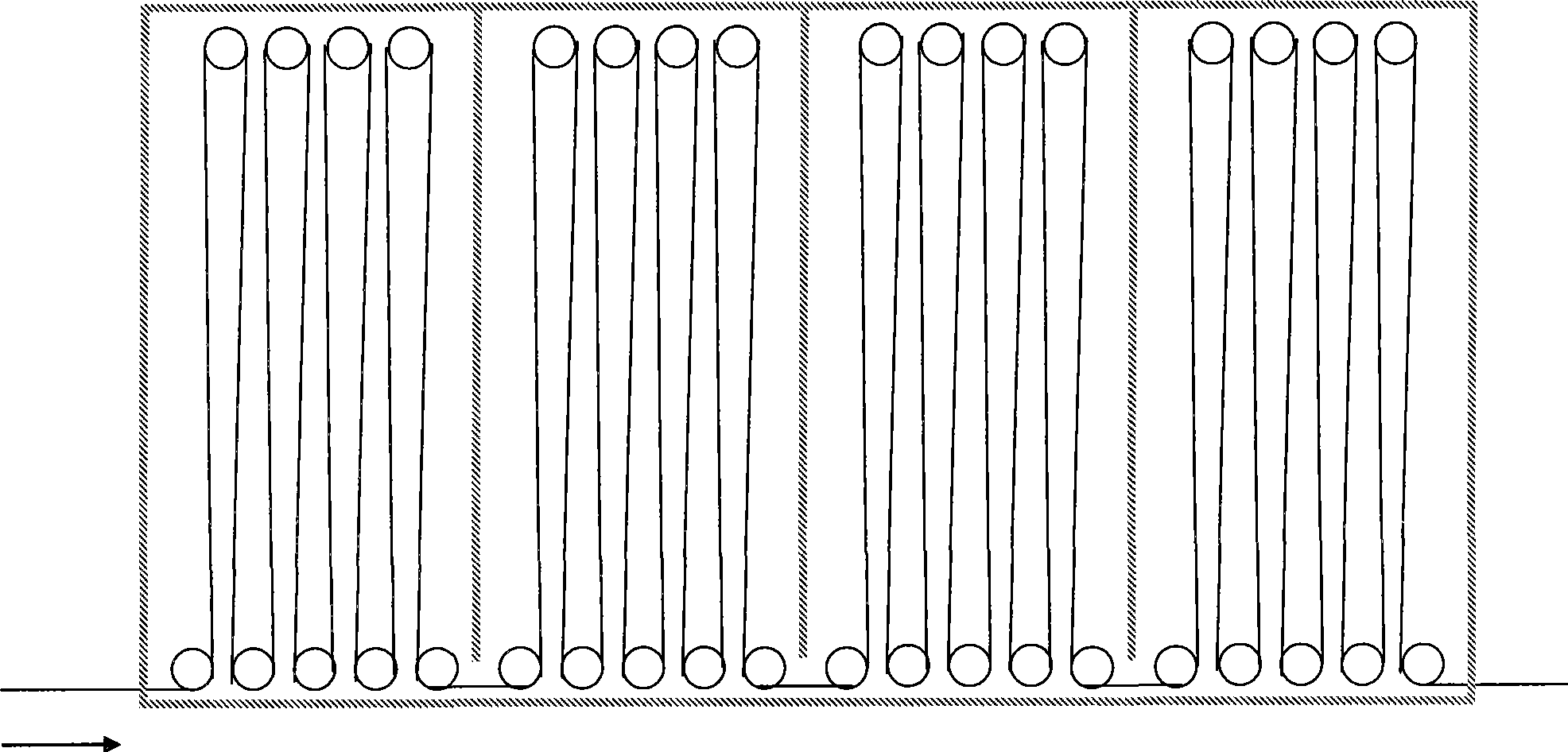

Image

Examples

Embodiment Construction

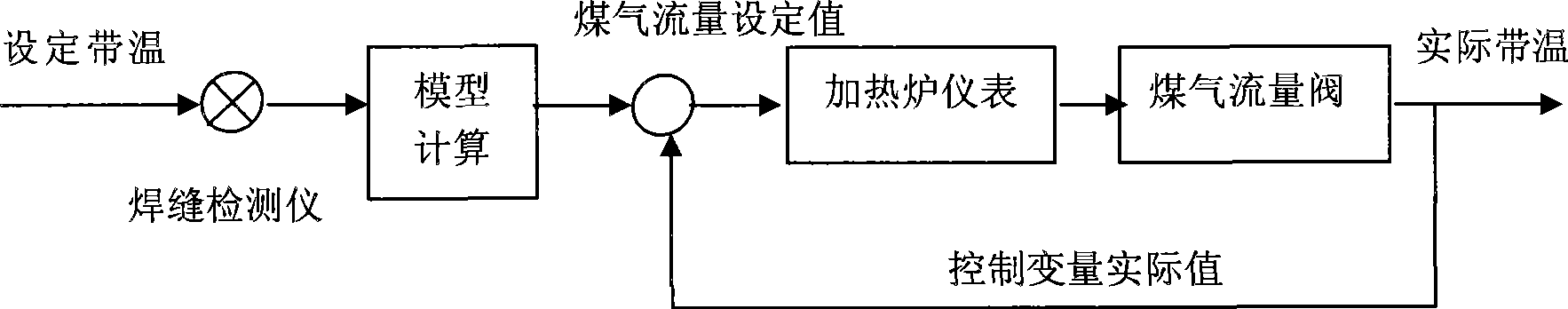

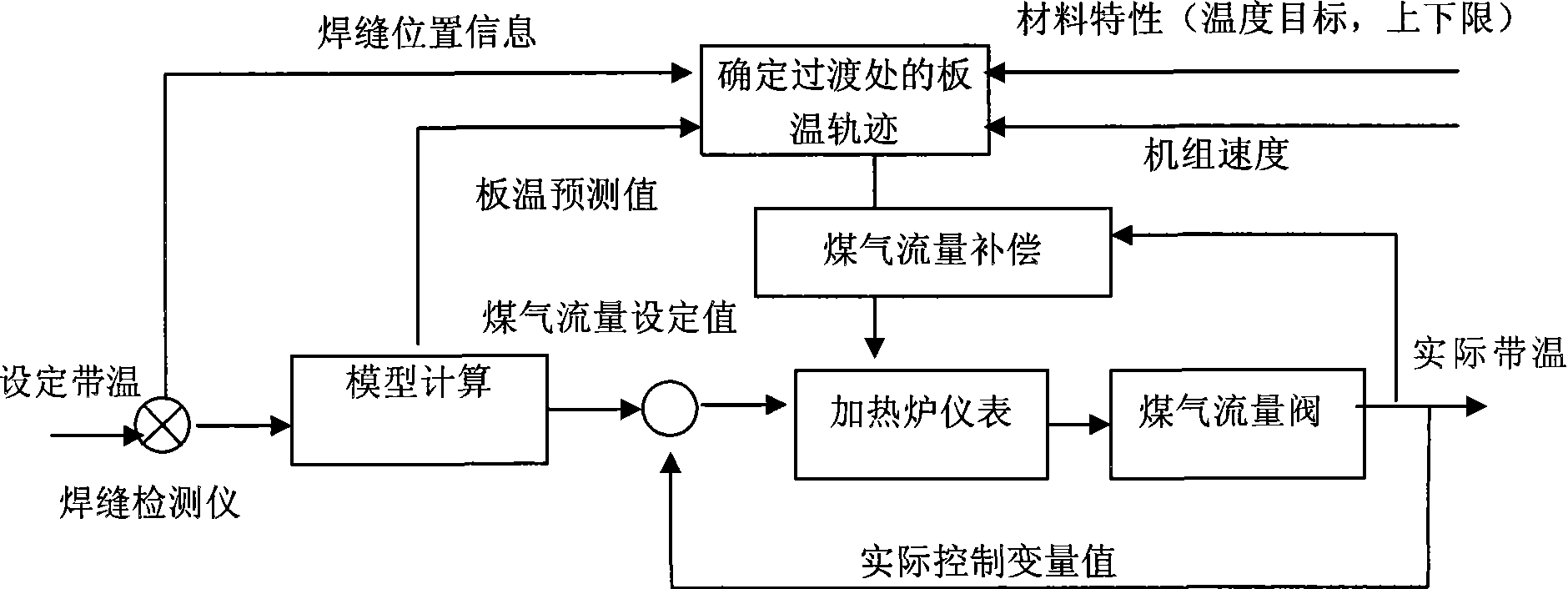

[0054] Such as image 3 , as shown in 4:

[0055] A. Use the weld detector to detect the strip weld within a certain distance before the next strip enters the heating furnace.

[0056] B. Using a mathematical model, calculate the predicted value Tout of the plate temperature of the strip steel at the exit of the heating furnace and the change of the plate temperature. The mathematical calculation formula:

[0057] Tout={TF-TSi} SVF+TSi

[0058] SVF ≡ Tout - TSi TF - TSi = 1 - exp [ - 1 s 1 ( TV - TVave ) + s 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com