Observation window for gas hood of paper machine

An observation window and paper machine technology, applied in the field of paper machines, can solve the problems of water holes in paper sheets, increased production consumption, and the inability to evacuate water vapor through rectangular observation windows, so as to reduce production consumption and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

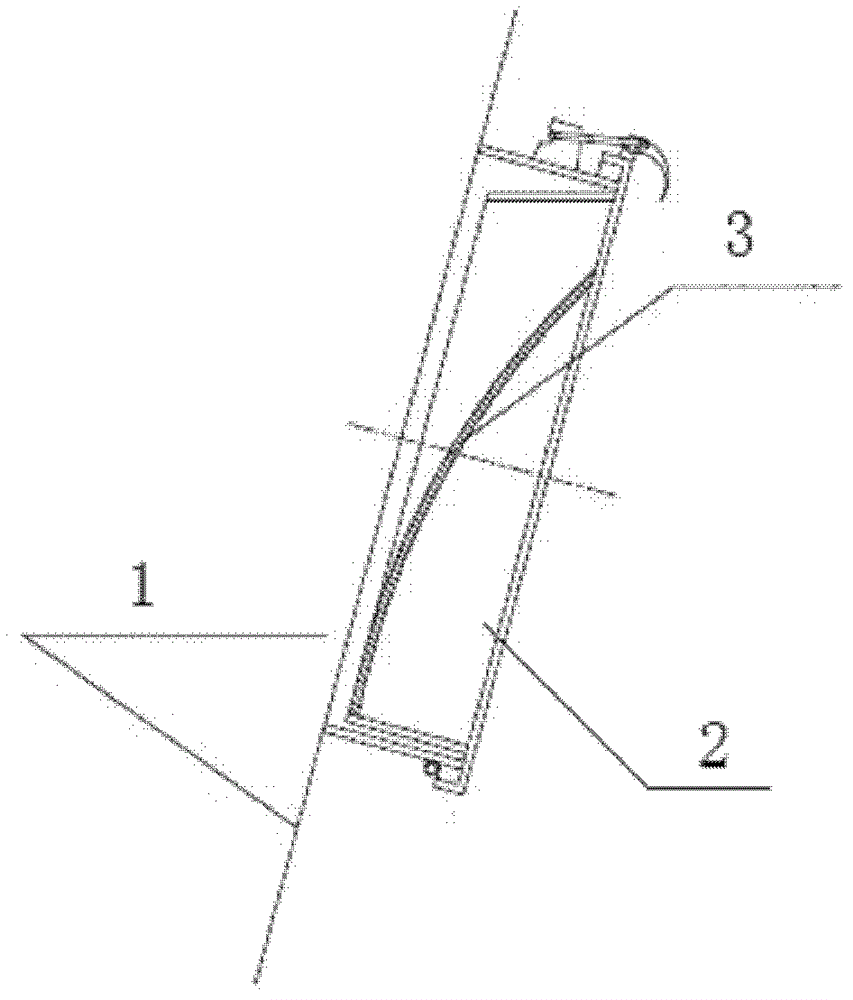

[0016] Such as figure 2 As shown, a paper machine gas hood observation window includes an observation window 2, and an air hood 1 connected to the observation window, and also includes a stainless steel plate 3, and the stainless steel plate 3 is welded inside the observation window 2, and is connected to the observation window 2 The bottom is inclined, and the size of the stainless steel plate is 450mm×350mm.

[0017] The water vapor at the observation window can be evacuated by the gas hood in time to avoid causing a large amount of steam to meet the observation window to form condensed water, and there will be no dripping phenomenon to ensure that the product is qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com