Method for restoring and reusing focusing coil

A technology of focusing coil and protective film, which is applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of high physical vapor deposition cost and unreusable focusing coil, etc., and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

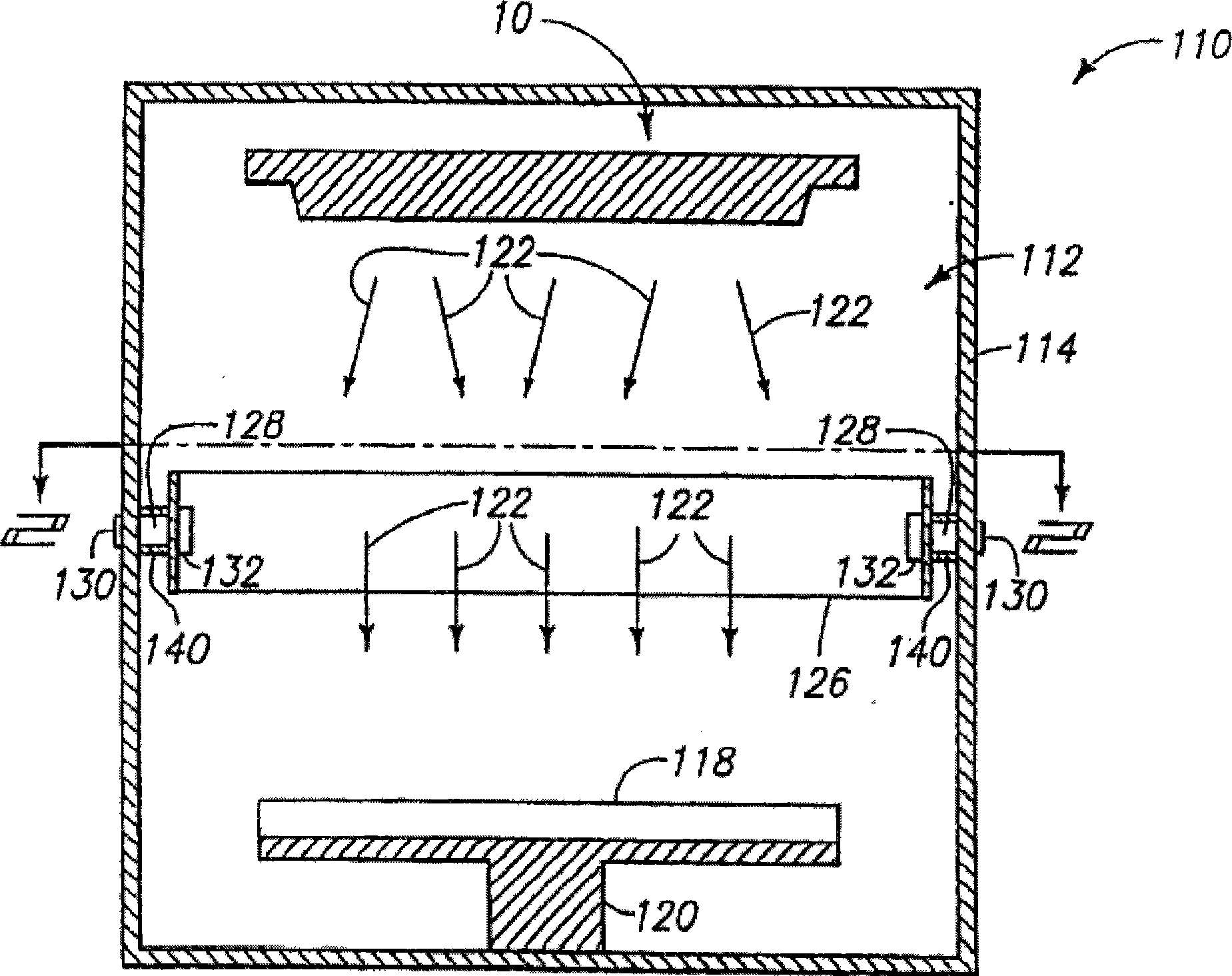

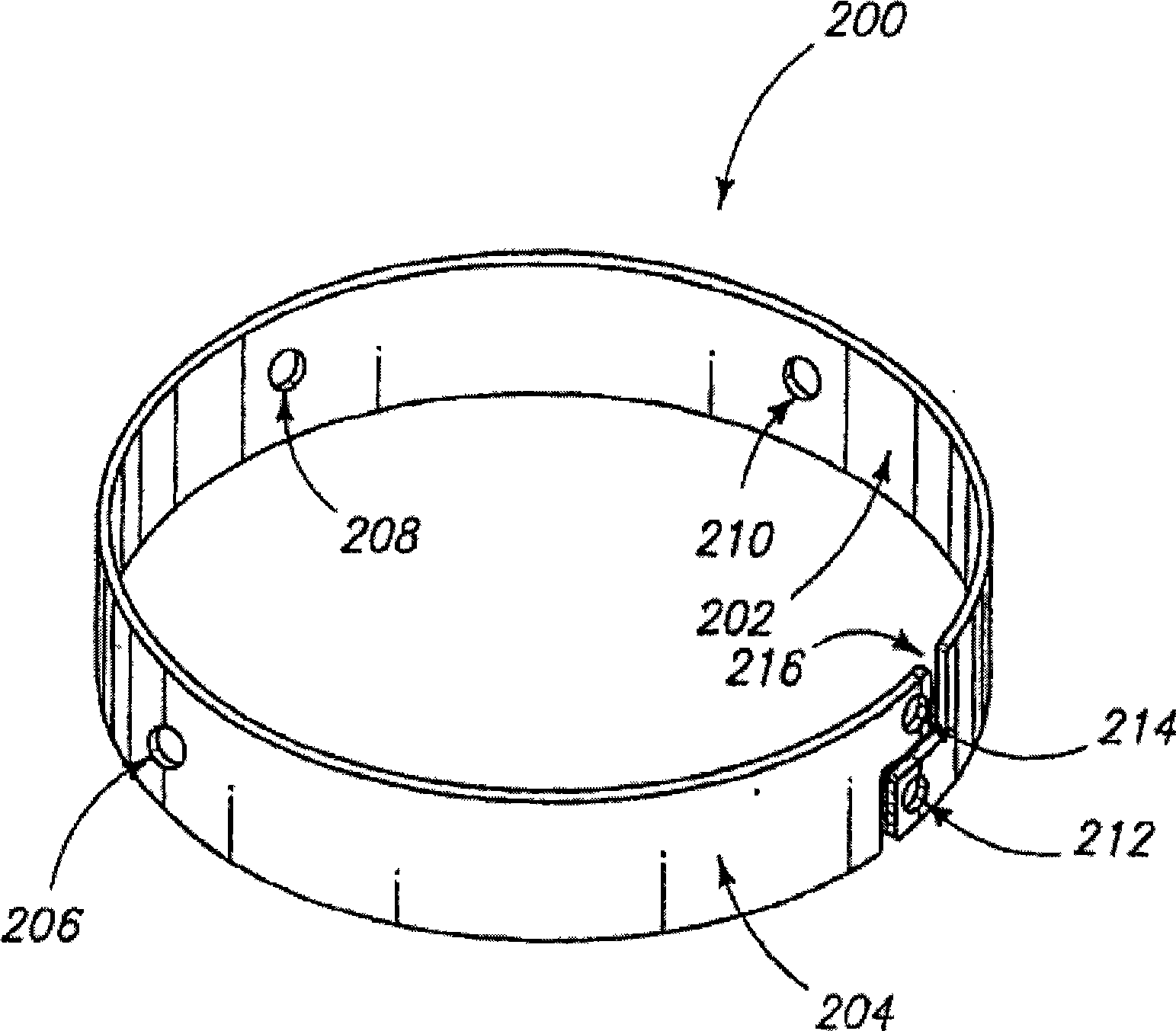

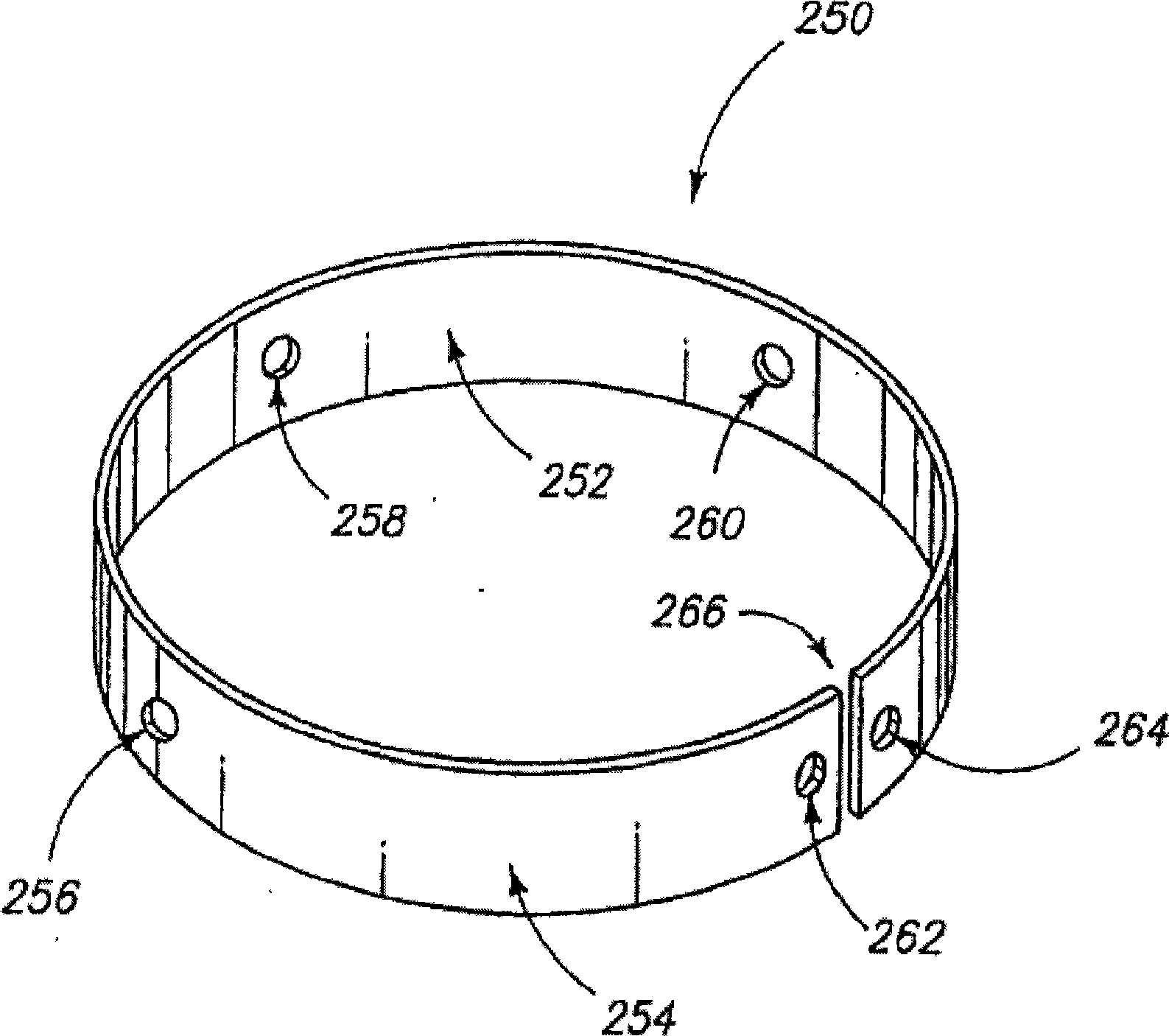

[0031] refer to Figure 4 As shown, an embodiment of the method for repairing and reusing the focusing coil of the present invention includes:

[0032] Step s1, coating the inner wall of the fixing hole on the used focusing coil with a protective film;

[0033] Step s2, corroding the focusing coil;

[0034] Step s3, after removing the sputtering material attached to the surface of the outer ring of the focusing coil, coating a protective film on the surface of the outer ring;

[0035] Step s4, continue to corrode the focusing coil;

[0036] Step s5, after removing the sputtering material attached to the surface of the inner ring of the focusing coil, removing the inner wall of the fixing hole and the protective film on the surface of the outer ring;

[0037] Step s6, roughening the surface of the inner ring of the focusing coil;

[0038] In step s7, the focusing coil is cleaned to remove residues produced by the rough treatment.

[0039] Through research on the used focus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com