Electromagnetic relay valve for electronic stability program of automobile

A technology of automotive electronics and relay valves, applied in the direction of brakes, valve details, valve devices, etc., can solve problems such as increased solenoid valve force, longer solenoid valve response time, and increased flow field pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

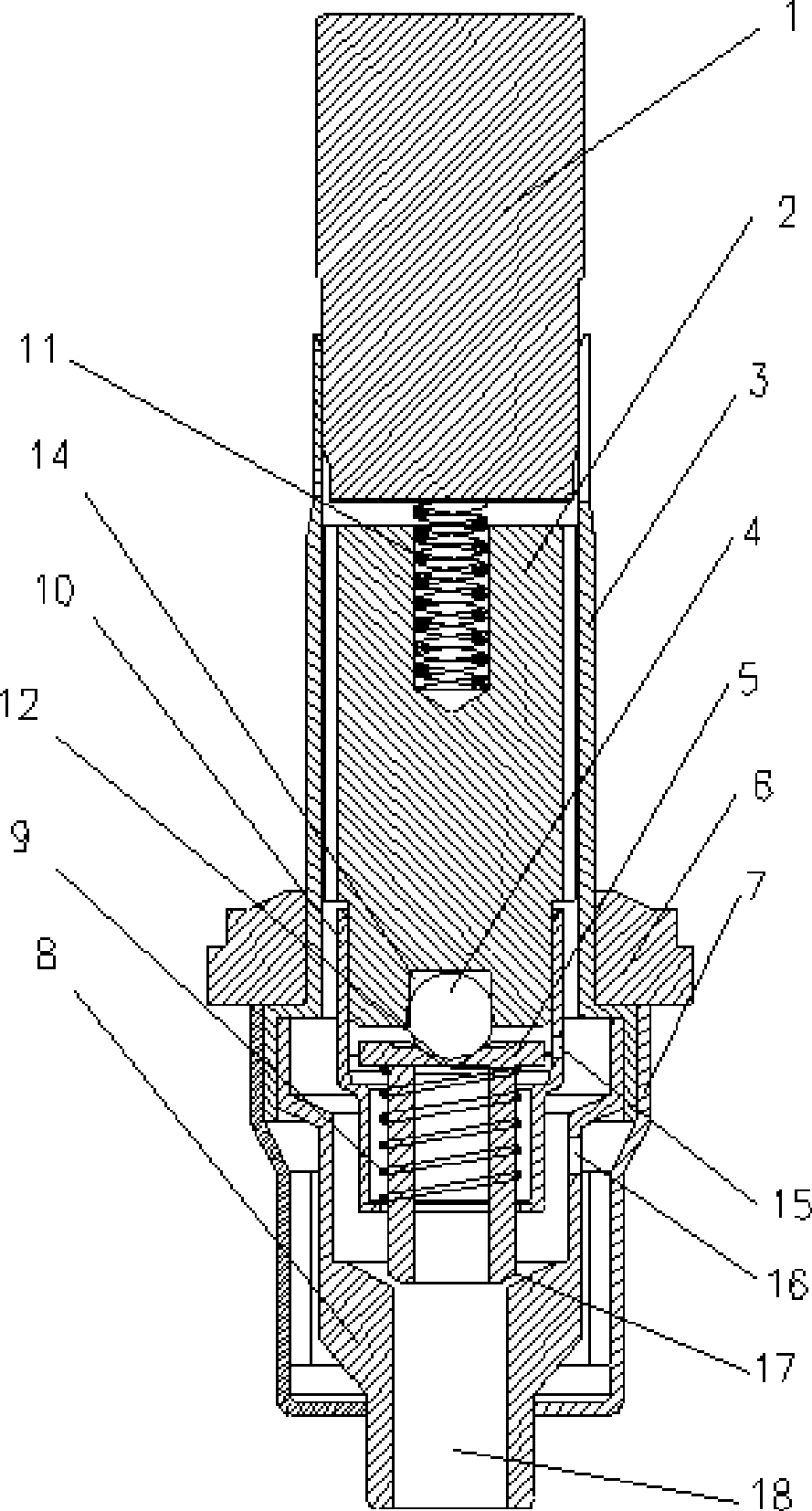

[0013] see figure 1 As shown, the valve body 8 is the base body of the entire electromagnetic relay valve assembly, and the material of the upper end of the valve body is the same as that of the magnetic isolation tube of the traditional solenoid valve, so it also plays the role of magnetic isolation. The upper end of the valve body 8 and the fixed iron 1 are fixedly connected together by spot welding. There is a certain gap between the moving iron 2 and the fixed iron 1. They are connected by the first spring 11, and the first spring 11 is guaranteed to have a certain gap. The amount of pressing, the steel ball 5 is used as a plug to be fixed in the top groove 14 of the moving iron 2 by riveting or spot welding. Of course, the plug can also be replaced with a semicircular body, a cone, etc., which are similar in shape to the steel ball 4 , such as welded on the top of the moving iron 2 . The valve core 5 is installed with the bottom up and the top down. Under the action of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com