Automatic degassing and oil changing device

An automatic and oil-drum technology, applied in the direction of transformer/inductor cooling, etc., can solve problems such as difficult to guarantee airtightness, error-prone, emergency shutdown, etc., to achieve equipment safety, airtightness, and airtightness sex guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

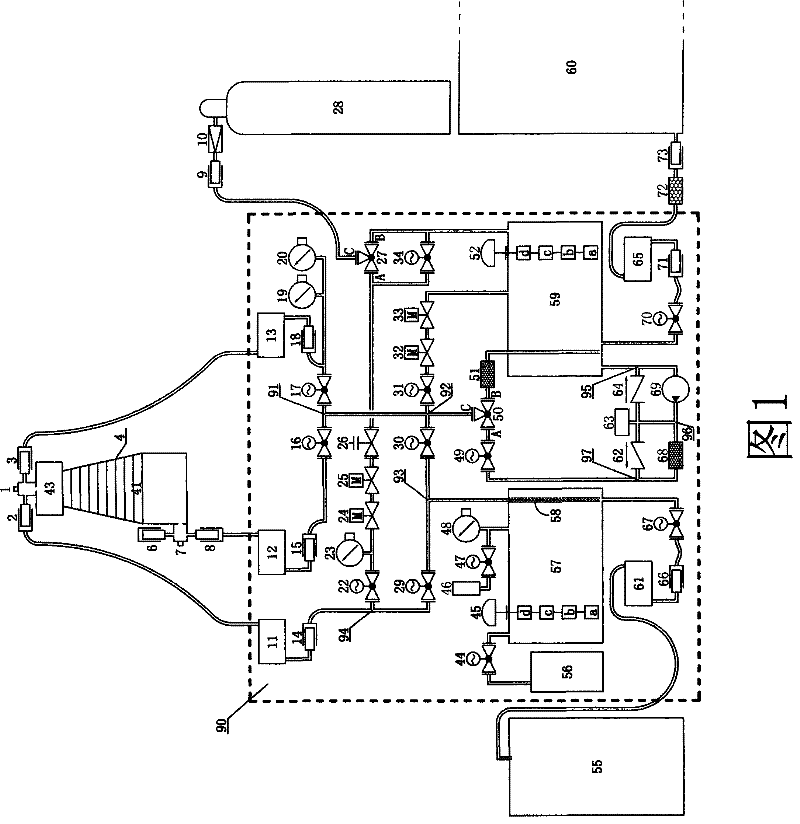

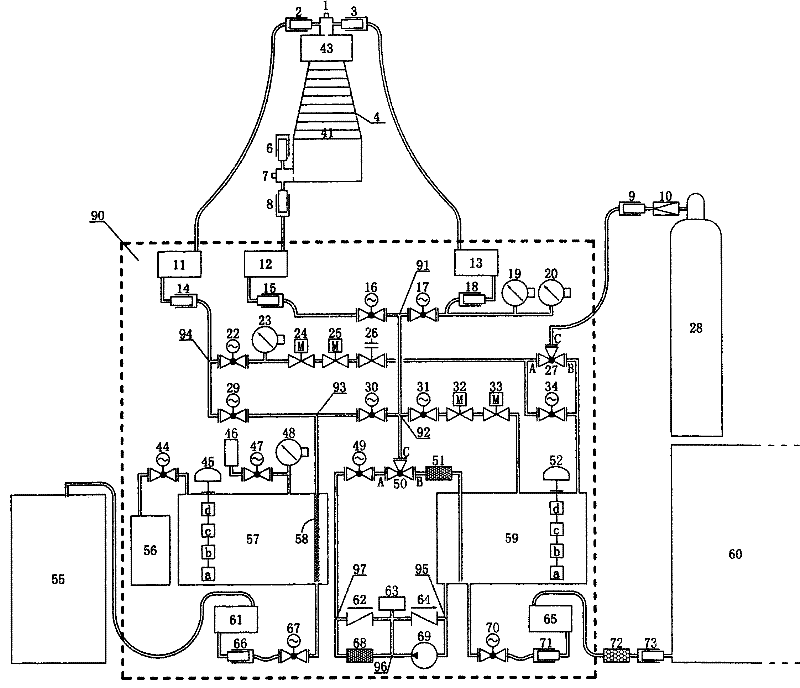

[0016] The invention as shown in Figure 1 is a kind of automatic degassing and oil changing device, comprises nitrogen bottle 28, high pressure transformer 4, automatic degassing and oil changing device 90, waste oil barrel 55, new oil barrel 60, wherein nitrogen bottle 28, The high voltage transformer 4, the waste oil barrel 55 and the new oil barrel 60 are respectively connected with the automatic degassing and oil changing device 90.

[0017] The high-voltage transformer 4 includes a body 41 and an expander 43 positioned on the top of the body 41. The bottom of the body 41 is connected with a vacuum refueling joint 7, and the vacuum refueling joint 7 is connected to the quick connectors 6 and 8 respectively, and the quick connector 8 is connected to the The pipeline in the automatic degassing and oil changing device 90 is connected, and the hose storage device 12, the quick joint 15 and the electric vacuum ball valve 16 are installed in sequence on the pipeline, and then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com