Extrusion die for metallic material

A metal material, extrusion die technology, applied in the direction of metal extrusion die, etc., can solve the problems of reduced dimensional accuracy of extruded items, difficulty in obtaining high quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

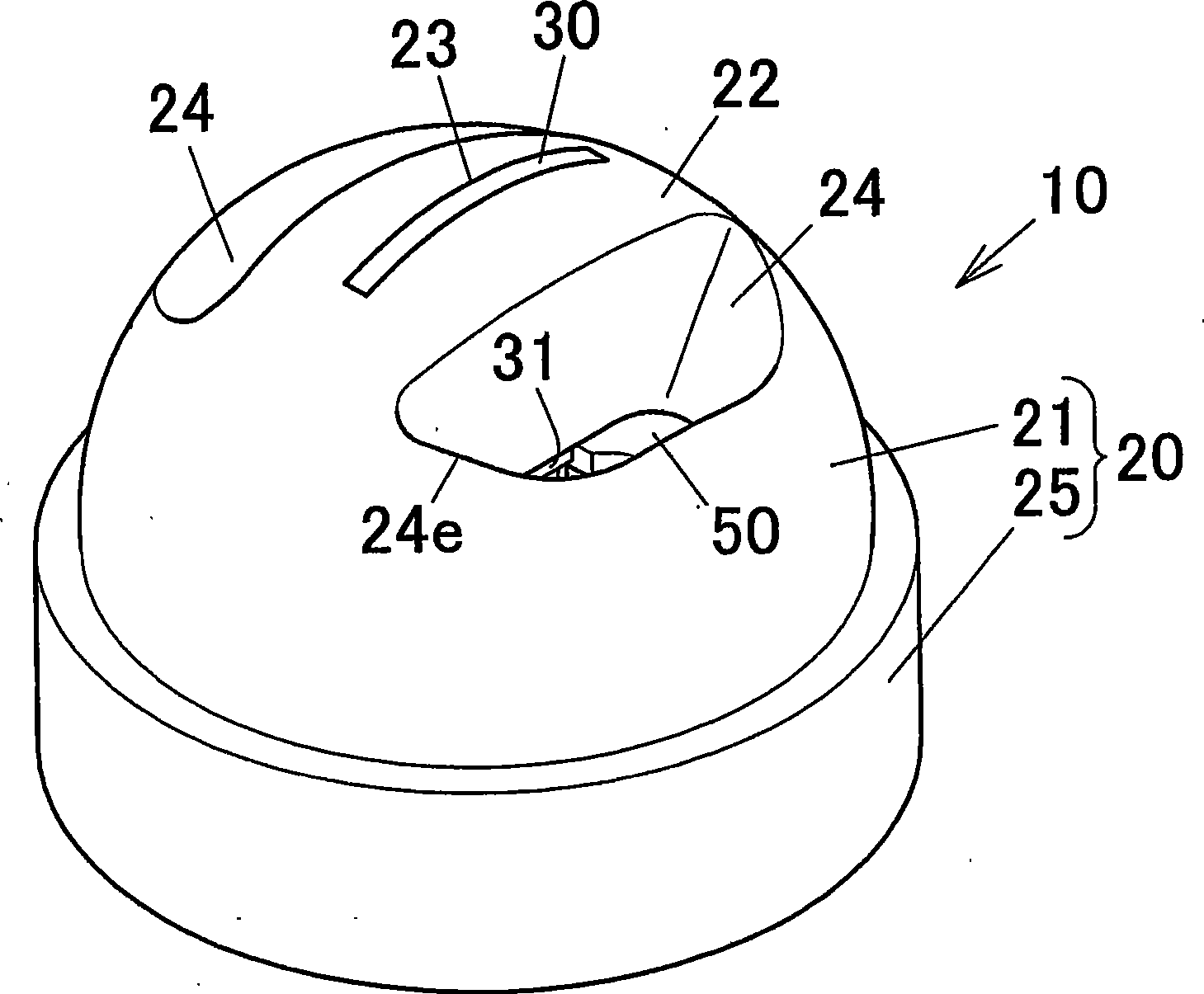

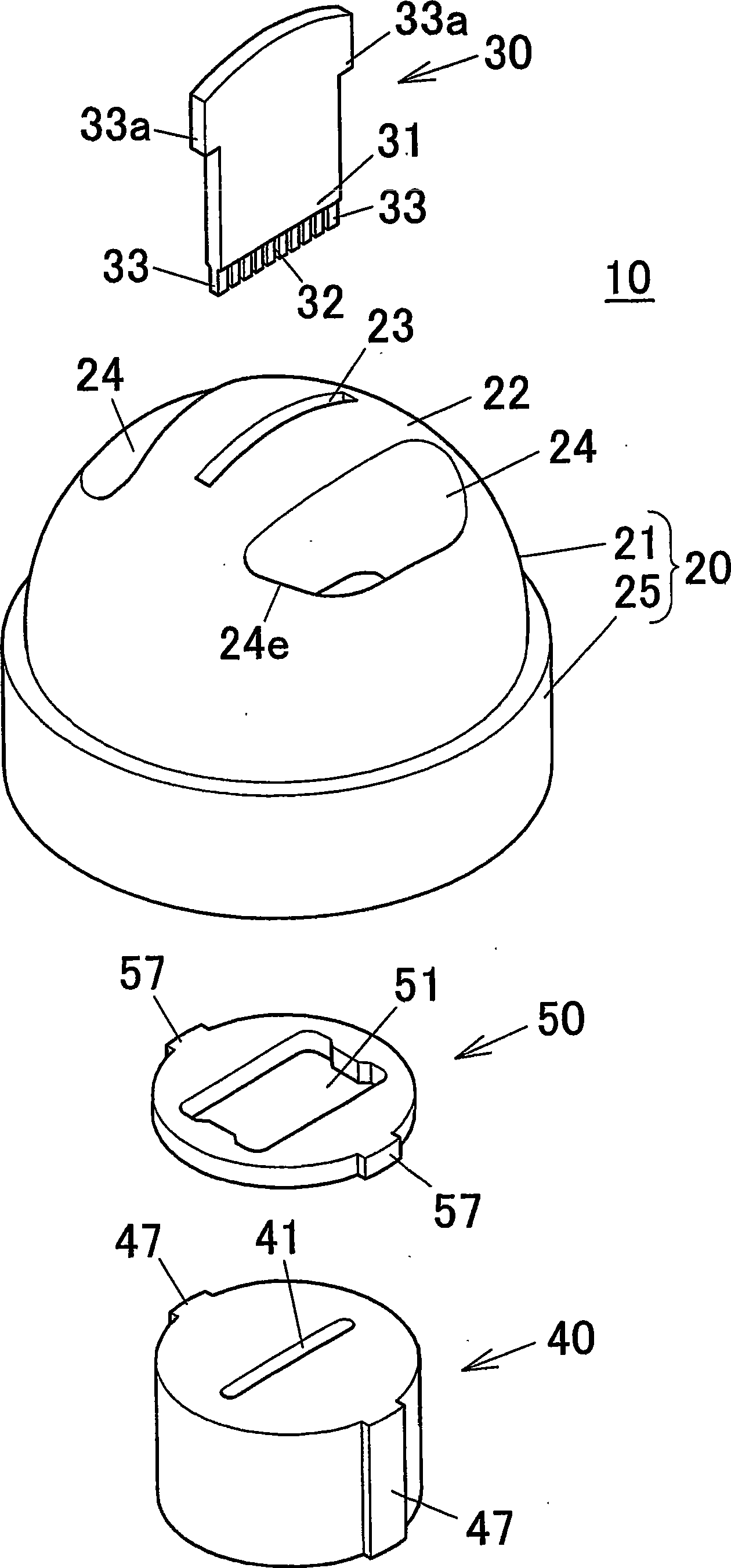

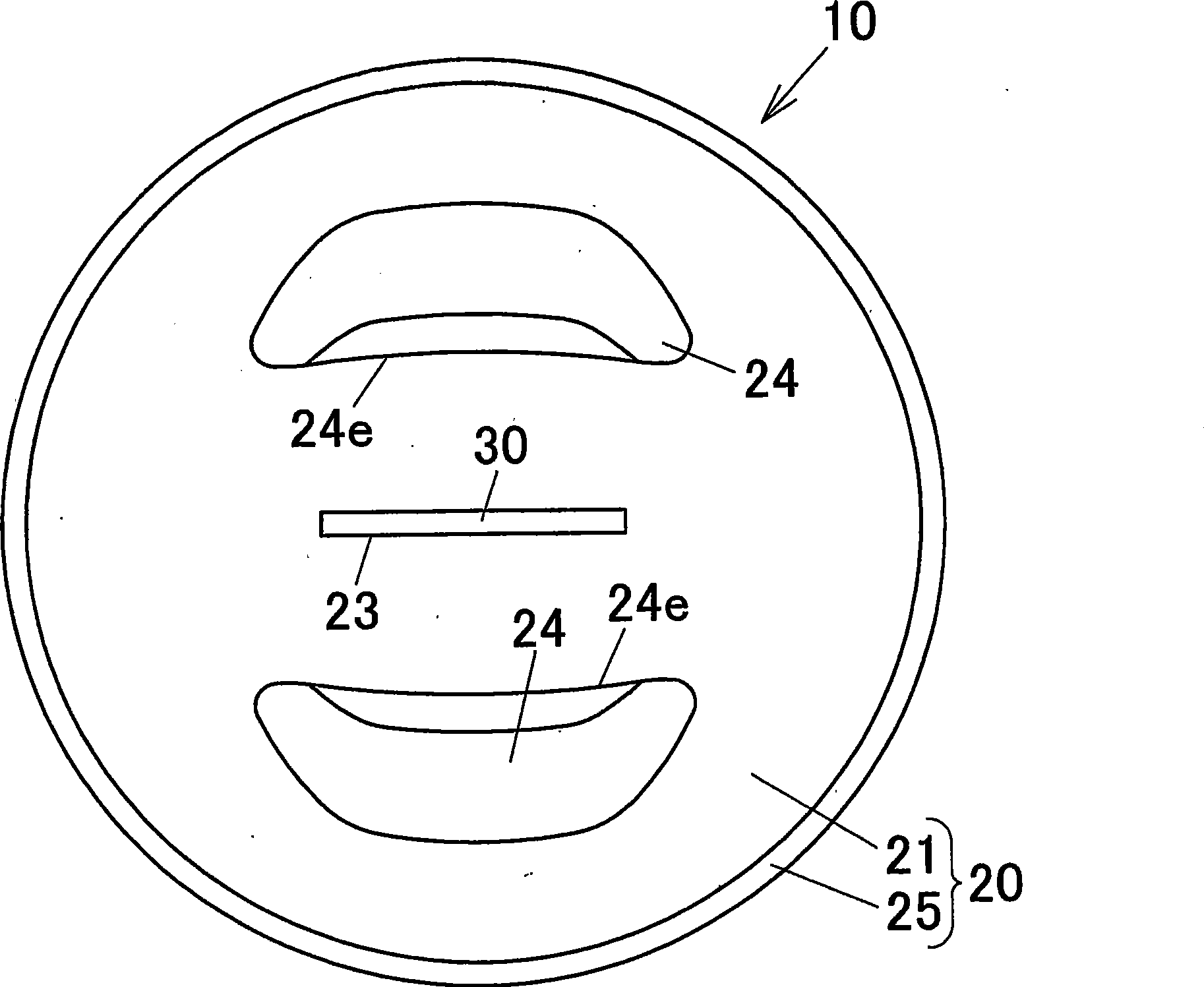

[0185] Figures 1 to 13 is an explanatory diagram showing an extrusion die for a metallic material according to a first embodiment of the present invention.

[0186] The extrusion die 10 for metallic materials according to the first embodiment is designed to extrude such as Figure 12 and 13 The multi-channel hollow part (multi-channel flat tube) 60 is shown.

[0187] The hollow member 60 is a metal member. In this embodiment, the hollow member 60 constitutes a heat exchange tube made of aluminum or an aluminum alloy.

[0188] The hollow member 60 is a flat member whose width is larger than the thickness and which is used in a heat exchanger (for example, a condenser for an automobile air conditioner). The hollow portion 61 of the hollow member 60 extends along the tube length direction and is divided into a plurality of heat exchange passages 63 by a plurality of partitions 62 arranged in parallel to each other. These channels 63 extend along the length of the tube and a...

example 1

[0251] As shown in Table 1, an extrusion die 10 according to the first embodiment was prepared. The pressure receiving portion 21 of the die case 20 of the die 10 has two channels 24 formed on both thickness direction sides of the extrusion hole 11 . The inclination angle θ of the tunnel 24 is adjusted to be 10°.

[0252] The billet pressure receiving surface 22 was formed in a 1 / 2 spherical configuration (convex spherical configuration) with a radius of 30 mm.

[0253] The ratio (2×Sb / Sa) of the planar state opening total area Sb of the cell inlet portion 24e to the planar state area Sa of the pressure receiving portion 21 was set to 0.1 (area ratio per cell was set to 0.05).

[0254] The male mold 30 is adjusted to: the height (thickness) of the mandrel 31 is 2.0 mm, the width of the mandrel 31 is 19.2 mm, the height of the channel forming protrusion 33 is 1.2 mm, the width of the channel forming protrusion 33 is 0.6 mm and the separation The width of the portion forming g...

example 2

[0260] As shown in Table 1, the ratio (2×Sb / Sa) of the planar state opening total area Sb of the cell inlet portion 24e to the planar state area Sa of the pressure receiving portion 21 is set to 0.15 (the area ratio of each cell is set to 0.075).

[0261] Except for the above, an extrusion die 10 having the same structure was prepared, and extrusion was performed in the same manner as above to be evaluated in the same manner as above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com